MEMS polysilicon nanofilm pressure sensor chip and manufacturing method thereof

A pressure sensor, polysilicon technology, applied in fluid pressure measurement by changing the ohmic resistance, measurement of the property force of the piezoelectric resistance material, etc., can solve the problems of low sensitivity ratio, good temperature characteristics, and thin pressure-sensitive film, etc. Achieve the effect of improving sensitivity, high linearity and improving linearity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

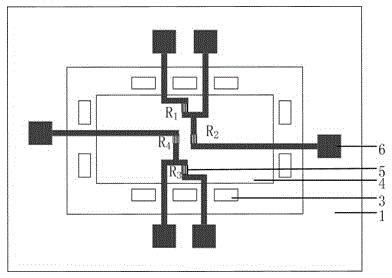

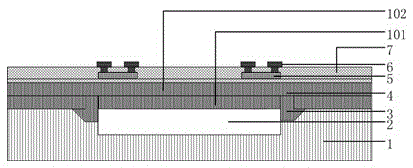

[0039] The present invention is a kind of MEMS polysilicon nano film pressure sensor chip, as figure 1 and figure 2 shown in . The sensor includes: a single crystal silicon substrate 1; on the single crystal silicon substrate 1, a pressure sensitive film 4 with a flat cross-section is arranged, with a film thickness of 3 μm and an area of 200 μm×100 μm; the pressure sensitive film 4 and the single crystal silicon substrate The bottom 1 is connected to form a closed cavity 2 between the two, and the height of the cavity is 1 μm; there are corrosion holes 3 around the edge of the pressure sensitive film 4, and after the sacrificial layer is etched and removed, it is sealed with polysilicon to form an approximate vacuum cavity; Four force-sensitive resistors 5 are arranged on the pressure film 4, and the force-sensitive resistors are P-type polysilicon nano-films; the four force-sensitive resistors 5 are connected by metal wires 6 to form a Wheatstone bridge, which converts p...

Embodiment 2

[0041] The present invention proposes a method for preparing a MEMS polysilicon nano-membrane pressure sensor chip, comprising the following steps:

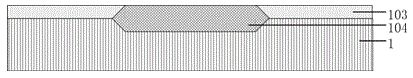

[0042] (1) image 3 Shown is the first thermal oxidation process. Deposit 0.2 μm thick silicon nitride on the single crystal silicon substrate by plasma enhanced chemical vapor deposition (PECVD) as a mask layer, then thermally oxidize and grow 1 μm thick silicon dioxide, and use phosphoric acid and hydrofluoric acid to remove the nitride respectively. Silicon and silicon dioxide, forming grooves with a depth of 0.5 μm on the silicon wafer.

[0043] (2) Figure 4 Shown is the second thermal oxidation process. Step (1) was repeated to form stepped grooves with two depths of 0.5 μm and 1 μm on the silicon wafer.

[0044] (3) Figure 5 Shown is the process of depositing the first layer of polysilicon. Use PECVD to deposit silicon dioxide in the groove, and use low pressure chemical vapor deposition (LPCVD) to deposit 1 μm thic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com