Fabric finishing agent and preparation method thereof

A fabric finishing agent and catalyst technology, which is applied in fiber treatment, textiles and papermaking, etc., can solve the problems of low natural degradation ability and high bioaccumulation, and achieve improved water and oil repellency, simple preparation process and mild reaction conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) After evacuating the self-made polymerization bottle for 1-2 hours, add PHMS (3g, 1.67mmol), 40%-80% THF, PEO (0.7g, 1.67mmol), AGE (0.23g, 1.67mmol) and Karstedt's The catalyst (20μl) was bubbled with nitrogen for 15-20min, and the temperature was raised to 60°C for 3-4h, then the temperature was lowered to 45°C and PFBE (1.968g, 6.68mmol) was added, the temperature was raised to 58°C, and hydrosilylation was carried out for 10-12h reaction.

[0042] (2) Pour out the polymer solution after cooling, distill under reduced pressure at 40°C to remove impurities such as small molecules and by-products, and dry in a vacuum oven for 24 hours.

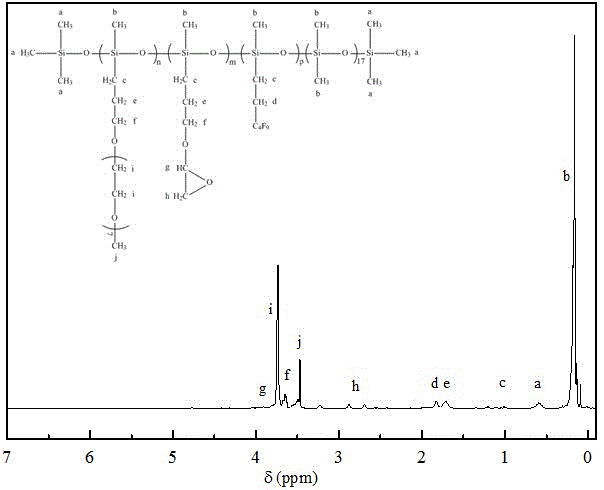

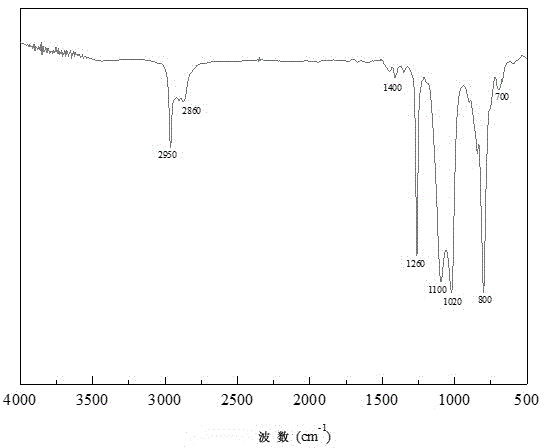

[0043] For products 1 HNMR and FTIR characterize the structure of the polymer, specifically as figure 1 and figure 2 shown.

Embodiment 2

[0045] (1) After evacuating the self-made polymerization bottle for 1-2 hours, add PHMS (3g, 1.67mmol), 40%-80% THF, PEO (0.7g, 1.67mmol), AGE (0.23g, 1.67mmol) and Karstedt's The catalyst (20μl) was bubbled with nitrogen for 15-20min, and the temperature was raised to 60°C for 3-4h, then the temperature was lowered to 45°C and PFHE (1.968g, 6.68mmol) was added, the temperature was raised to 58°C, and hydrosilylation was carried out for 10-12h reaction.

[0046] (2) Pour out the polymer solution after cooling, distill under reduced pressure at 40°C to remove impurities such as small molecules and by-products, and dry in a vacuum oven for 24 hours.

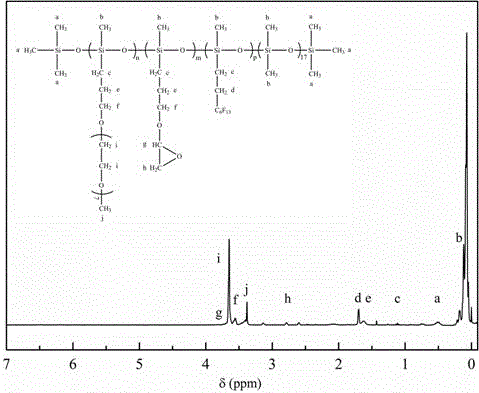

[0047] For products 1 HNMR and FTIR characterize the structure of the polymer, specifically as image 3 and Figure 4 shown.

Embodiment 3

[0049](1) After evacuating the self-made polymerization bottle for 1 to 2 hours, add PHMS (3g, 1.67mmol), 40% to 80% THF, PEO (1.4g, 3.34mmol), AGE (0.23g, 1.67mmol) and Karstedt's The catalyst (20μl) was bubbled with nitrogen for 15-20min, and the temperature was raised to 60°C for 3-4h, then the temperature was lowered to 45°C and PFBE (1.476g, 5.01mmol) was added, the temperature was raised to 58°C, and hydrosilylation was carried out for 10-12h reaction.

[0050] (2) Pour out the polymer solution after cooling, distill under reduced pressure at 40°C to remove impurities such as small molecules and by-products, and dry in a vacuum oven for 24 hours. For products 1 HNMR and FTIR characterize the structure of the polymer, specifically as figure 1 and figure 2 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com