Platinum-copper alloy nano particle and preparation method thereof

A platinum-copper alloy and nanoparticle technology, applied in nanotechnology and other directions, can solve the problems affecting the morphology and structure of platinum nanoparticles and catalytic activity, and the removal method and process are cumbersome. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

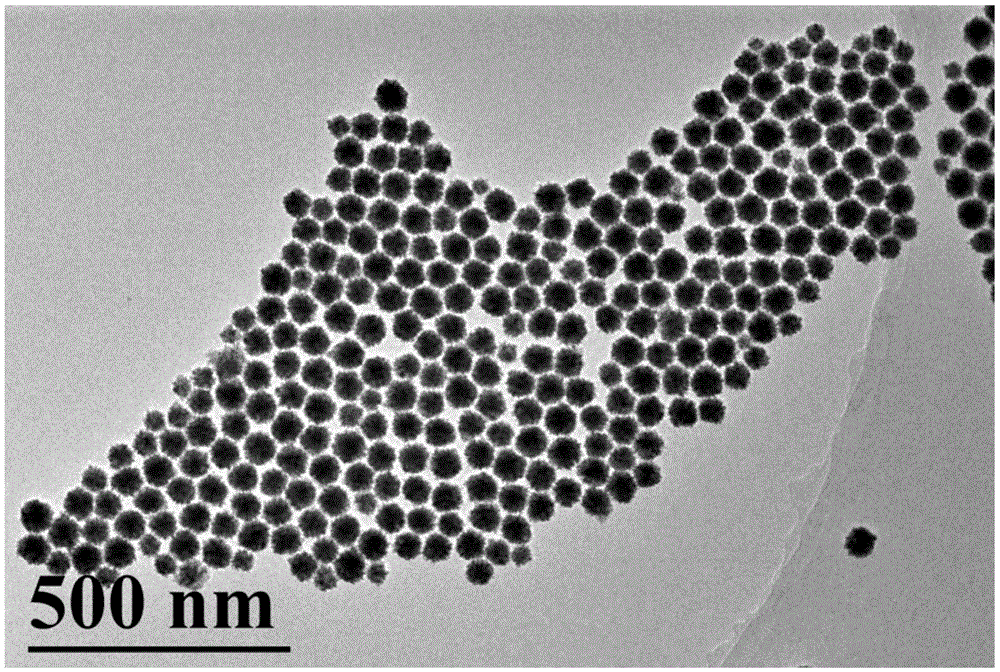

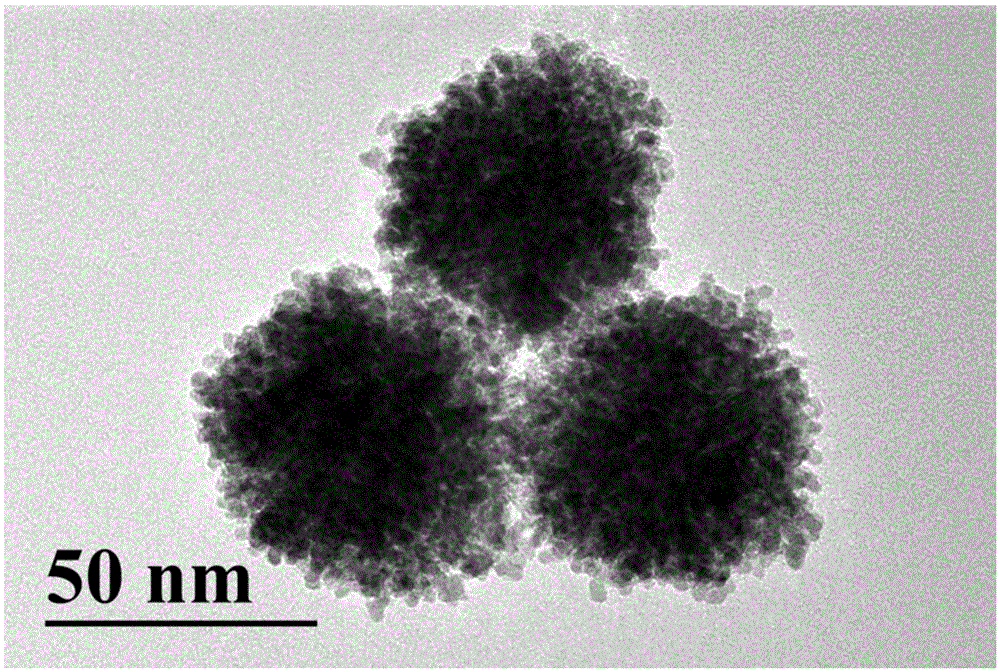

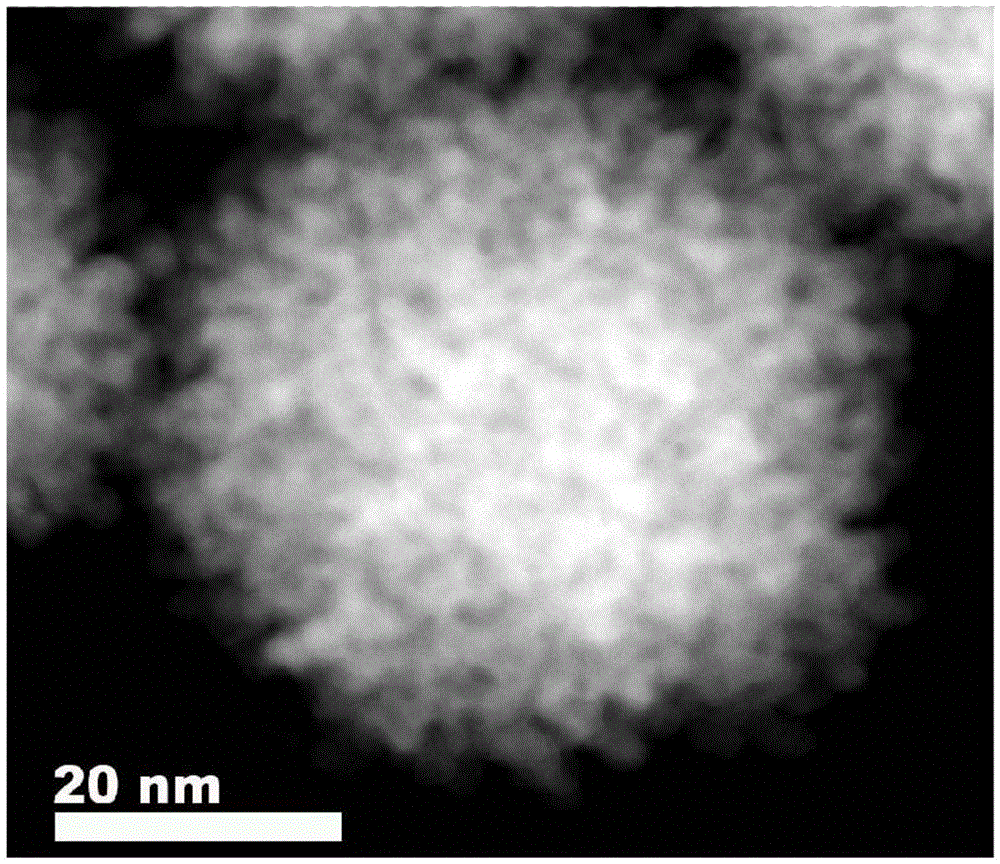

Image

Examples

Embodiment 1

[0047] A preparation method of platinum-copper alloy nanoparticles, comprising the steps of:

[0048] (1) Potassium tetrachloroplatinate (K) of preparation 10mmol / L 2 PtCl 4 ) solution, 1mol / L copper sulfate (CuSO4 ) solution and the L-ascorbic acid solution of 0.1mol / L;

[0049] (2) Add the magnetic rotor, 4.5mL ultrapure water, the 0.3mL potassium tetrachloroplatinate solution and 1 μL copper sulfate solution prepared above into a 10 ml glass vial in sequence, and stir for 10 minutes to make the solution mix evenly, and obtain Mixed aqueous solution;

[0050] (3) Quickly add 0.2mL of the L-ascorbic acid solution prepared above into the mixed aqueous solution, heat in a water bath to 60°C, and stir vigorously for 2 hours;

[0051] (4) after completion of the reaction, after the gained solution was centrifuged with 12000rpm rotating speed for 10min, the supernatant was removed to obtain a solid product, and in the gained solid product, water and ethanol mixed solution (wate...

Embodiment 2

[0055] A preparation method of platinum-copper alloy nanoparticles, comprising the steps of:

[0056] (1) Potassium tetrachloroplatinate (K) of preparation 10mmol / L 2 PtCl 4 ) solution, 1mol / L copper sulfate (CuSO 4 ) solution and the L-ascorbic acid solution of 0.1mol / L;

[0057] (2) Add the magnetic rotor, 4.0mL ultrapure water, the 0.6mL potassium tetrachloroplatinate solution and 1 μL copper sulfate solution prepared above into a 10 ml glass vial in sequence, and stir for 10 minutes to make the solution mix evenly, to obtain Mixed aqueous solution;

[0058] (3) Add 0.4 mL of L-ascorbic acid prepared above to the mixed aqueous solution quickly, and heat to 60° C. in a water bath, and stir vigorously for 2 hours;

[0059] (4) after completion of the reaction, after the gained solution was centrifuged with 12000rpm rotating speed for 10min, the supernatant was removed to obtain a solid product, and in the gained solid product, water and ethanol mixed solution (water: etha...

Embodiment 3

[0062] A preparation method of platinum-copper alloy nanoparticles, comprising the steps of:

[0063] (1) Potassium tetrachloroplatinate (K) of preparation 10mmol / L 2 PtCl 4 ) solution, 1mol / L copper sulfate (CuSO 4 ) solution and the L-ascorbic acid solution of 0.1mol / L;

[0064] (2) Add the magnetic rotor, 4.5mL ultrapure water, the 0.3mL potassium tetrachloroplatinate solution and 3 μL copper sulfate solution prepared above into a 10 ml glass vial in turn, and stir for 10 minutes to make the solution mix evenly, and obtain Mixed aqueous solution;

[0065] (3) Quickly add 0.2mL of L-ascorbic acid prepared above into the mixed aqueous solution, heat in a water bath to 60°C, and stir vigorously for 2 hours;

[0066] (4) after completion of the reaction, after the gained solution was centrifuged with 12000rpm rotating speed for 10min, the supernatant was removed to obtain a solid product, and in the gained solid product, water and ethanol mixed solution (water: ethanol volu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com