A kind of green preparation method of modified chitosan-nanometer silver sol

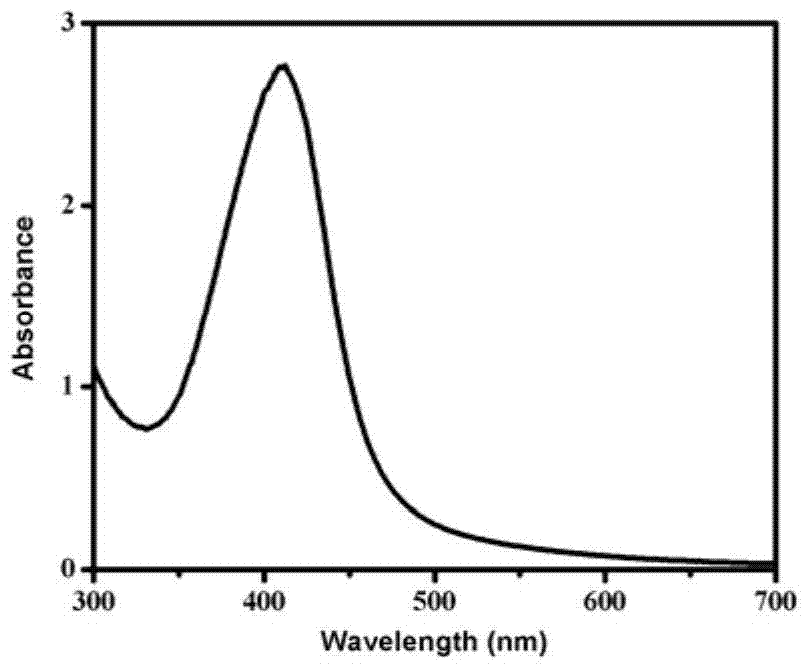

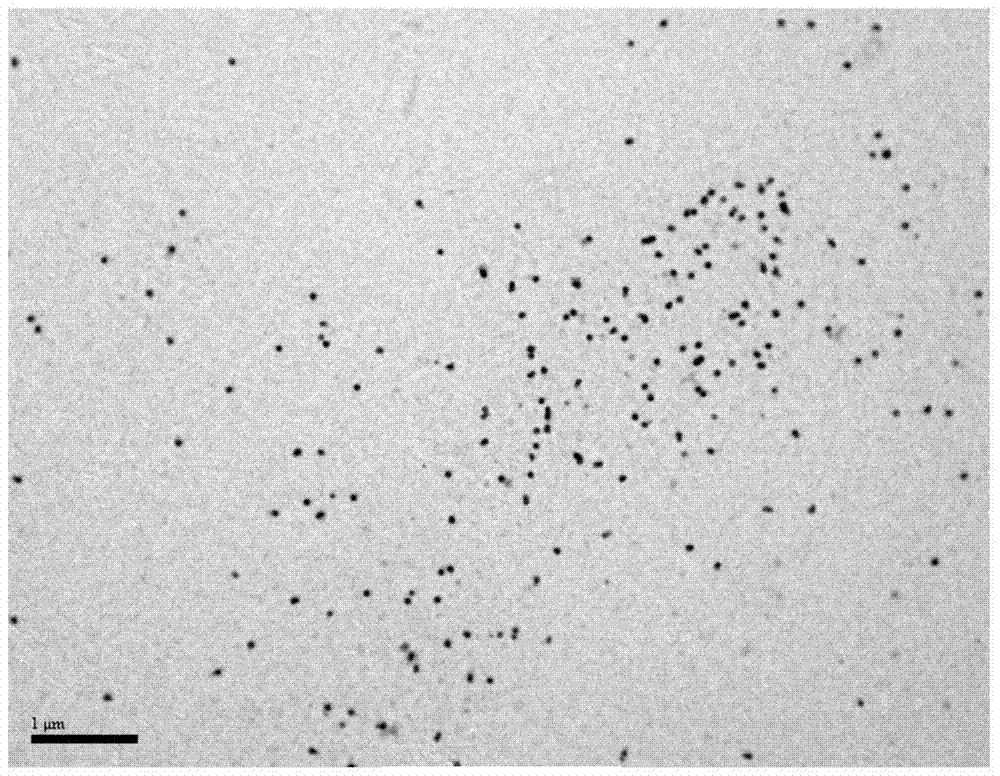

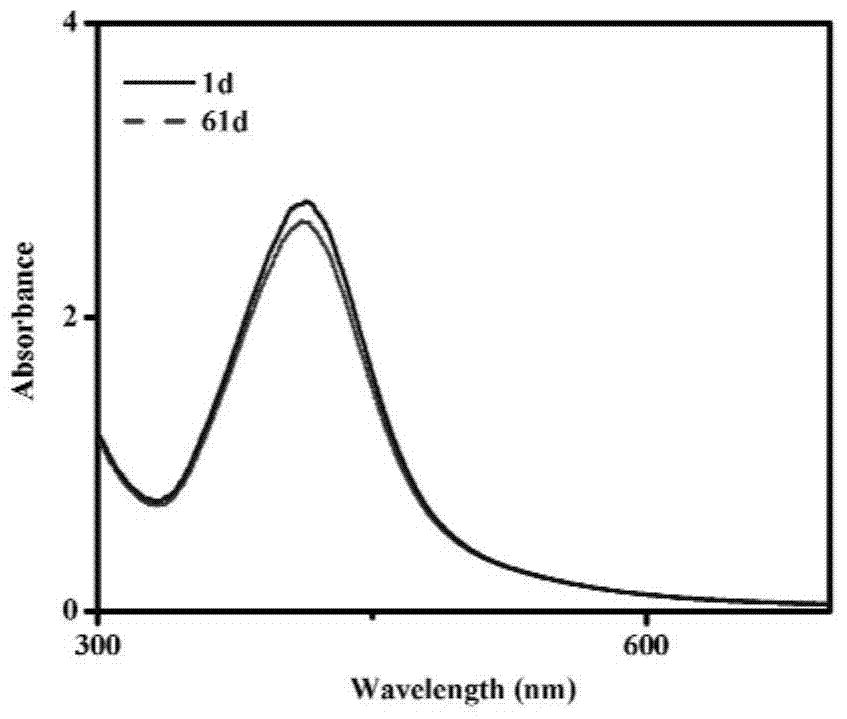

A technology of nano-silver sol and chitosan, which is applied in metal processing equipment, transportation and packaging, etc., can solve the problems of poor water solubility and restrictions on the application of chitosan-nano-silver sol, and achieve strong antibacterial properties and stable dispersion , the effect of reducing cytotoxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1) Disperse the chitosan powder in deionized water, adjust the pH to 5.0, and prepare a chitosan aqueous solution with a mass concentration of 0.1%; add 3-(2,4-dihydroxy)phenyl in the chitosan aqueous solution Propionic acid (HCA), make its molar concentration be 30% of amino molar concentration in chitosan, then add 1-ethyl-(3-dimethylaminopropyl) carbodiimide hydrochloride (EDC) As a catalyst, make its molar concentration 30% of the amino molar concentration in chitosan, react at 40°C for 12 hours to obtain an aqueous solution of modified chitosan, obtain modified chitosan after dialysis and freeze-drying;

[0026] 2) dissolving the modified chitosan obtained in the step 1) in deionized water, and being mixed with a modified chitosan aqueous solution whose mass concentration is 1%;

[0027] 3) dissolving silver nitrate in deionized water to prepare a silver nitrate aqueous solution with a mass concentration of 20%;

[0028] 4) Under dark conditions, take 1 mL of modi...

Embodiment 2

[0030] 1) Disperse the chitosan powder in deionized water, adjust the pH to 5.0, and prepare a chitosan aqueous solution with a mass concentration of 0.5%; add 3-(2,4-dihydroxy)phenyl in the chitosan aqueous solution Propionic acid (HCA), make its molar concentration be 40% of amino molar concentration in chitosan, then add 1-ethyl-(3-dimethylaminopropyl) carbodiimide hydrochloride (EDC) As a catalyst, make its molar concentration 40% of the molar concentration of amino groups in chitosan, react at 40°C for 18 hours to obtain an aqueous solution of modified chitosan, obtain modified chitosan after dialysis and freeze-drying;

[0031] 2) the modified chitosan obtained in the step 1) is dissolved in deionized water, and is mixed with a modified chitosan aqueous solution whose mass concentration is 3%;

[0032] 3) dissolving silver nitrate in deionized water to prepare a silver nitrate aqueous solution with a mass concentration of 30%;

[0033] 4) Under the condition of avoiding...

Embodiment 3

[0035] 1) Disperse the chitosan powder in deionized water, adjust the pH to 5.0, and prepare a chitosan aqueous solution with a mass concentration of 1%; add 3-(2,4-dihydroxy)phenyl in the chitosan aqueous solution Propionic acid (HCA), make its molar concentration be 60% of amino molar concentration in chitosan, then add 1-ethyl-(3-dimethylaminopropyl) carbodiimide hydrochloride (EDC) As a catalyst, make its molar concentration 60% of the molar concentration of amino groups in chitosan, react at 30°C for 24 hours to obtain an aqueous solution of modified chitosan, obtain modified chitosan after dialysis and freeze-drying;

[0036] 2) the modified chitosan obtained in the step 1) is dissolved in deionized water, and is mixed with a modified chitosan aqueous solution whose mass concentration is 5%;

[0037] 3) dissolving silver nitrate in deionized water to prepare a silver nitrate aqueous solution with a mass concentration of 50%;

[0038] 4) Under dark conditions, take 5 mL ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of deacetylation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com