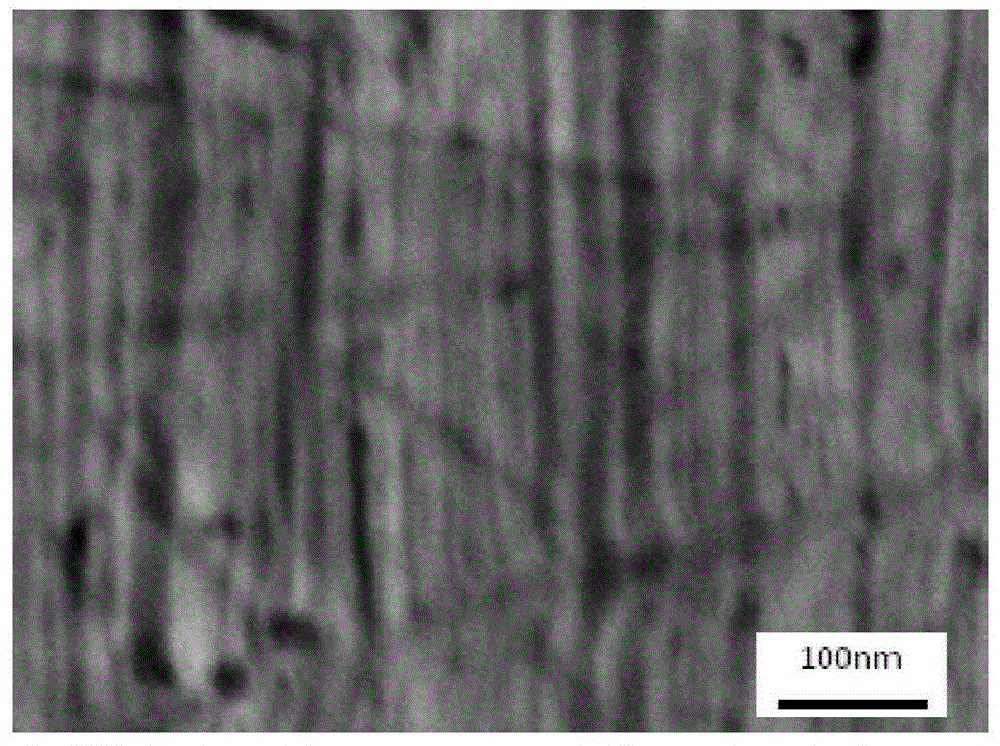

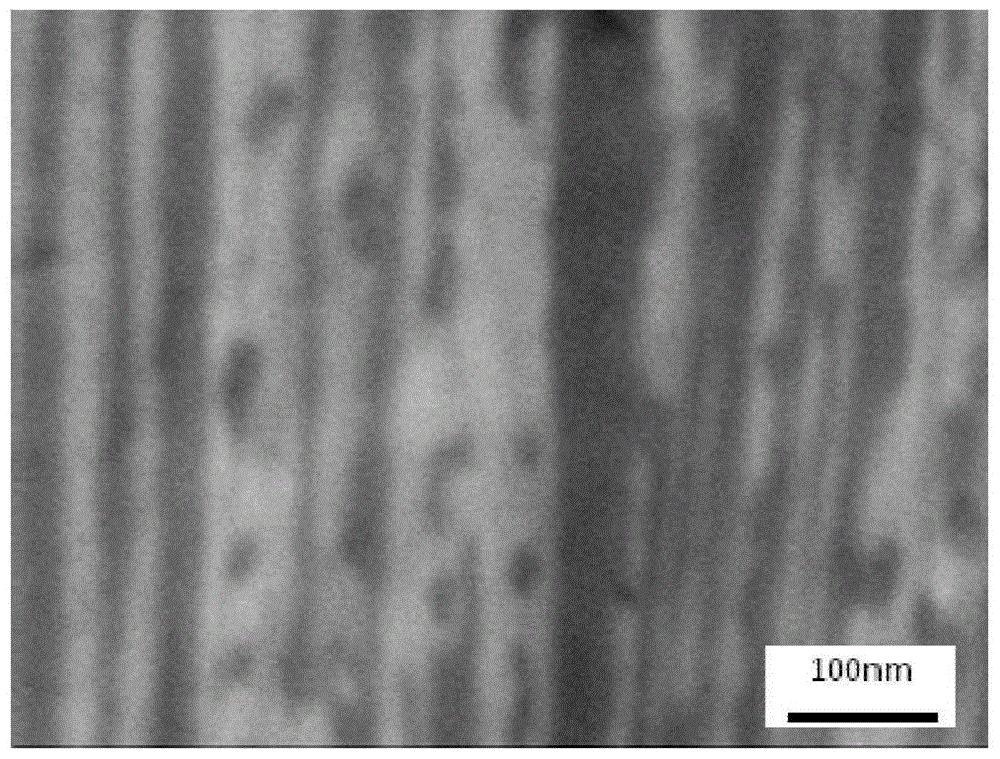

Method for preparing nanoscale multilayer metal matrix composites combined with magnetic field heat treatment

A multi-layer metal and composite material technology, applied in metal rolling and other directions, can solve the problem of inability to prepare multi-layer nano-scale metal materials, and achieve the effect of enhancing texture orientation and inhibiting coarsening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A method for preparing a nanoscale silver-nickel multilayer metal matrix composite material in combination with magnetic field heat treatment, comprising the following steps:

[0047] Step 1, pretreatment of the substrate:

[0048] (1) The substrate is silver and nickel;

[0049] Among them, the thickness of the substrates is 0.05mm, and the number of substrates is 20 silver substrates and 20 nickel substrates;

[0050] (2) Anneal the substrate under vacuum: the degree of vacuum is 10*10 -2Pa, the annealing temperature of the silver substrate is 400°C, and the annealing time is 30min; the annealing temperature of the nickel substrate is 700°C, and the annealing time is 60min; the internal stress of each substrate is removed after annealing;

[0051] (3) Clean both sides of the substrate, polish, remove scale, and after cleaning the surface with acetone to remove oily impurities, cut into a cuboid, wherein the length and width of each substrate after cutting are equal ...

Embodiment 2

[0077] A method for preparing a nanoscale silver-nickel multilayer metal matrix composite material in combination with magnetic field heat treatment, comprising the following steps:

[0078] Step 1, pretreatment of the substrate:

[0079] (1) The substrate is silver and nickel;

[0080] Among them, the thickness of the substrates is 0.1mm, and the number of substrates is 10 silver substrates and 10 nickel substrates;

[0081] (2) Anneal the substrate under the protection of high-purity argon: the annealing temperature of the silver substrate is 450°C, and the annealing time is 20min; the annealing temperature of the nickel substrate is 600°C, and the annealing time is 90min; The internal stress of each substrate is removed;

[0082] (3) Clean both sides of the substrate, polish, remove scale, and after cleaning the surface with acetone to remove oily impurities, cut into a cuboid, wherein the length and width of each substrate after cutting are equal respectively, and the th...

Embodiment 3

[0108] A method for preparing a nanoscale copper-iron multilayer metal matrix composite material in combination with magnetic field heat treatment, comprising the following steps:

[0109] Step 1, pretreatment of the substrate:

[0110] (1) The substrate is copper and iron;

[0111] Among them, the thickness of the substrates is 0.1mm, and the number of substrates is 10 copper substrates and 10 iron substrates;

[0112] (2) Anneal the substrate under vacuum: the degree of vacuum is 10*10 -2 Pa, the annealing temperature of the copper substrate is 400°C, and the annealing time is 40min; the annealing temperature of the iron substrate is 500°C, and the annealing time is 60min; the internal stress of each substrate is removed after annealing;

[0113] (3) Clean both sides of the substrate, polish, remove scale, and after cleaning the surface with acetone to remove oily impurities, cut into a cuboid, wherein the length and width of each substrate after cutting are equal respective...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com