Method for manufacturing nanoscale multilayer metal matrix composite with combination of magnetic field heat treatment

A multi-layer metal and composite material technology, applied in metal rolling and other directions, can solve the problems of inability to prepare multi-layer nano-scale metal materials, and achieve the effect of enhancing texture orientation and inhibiting coarsening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

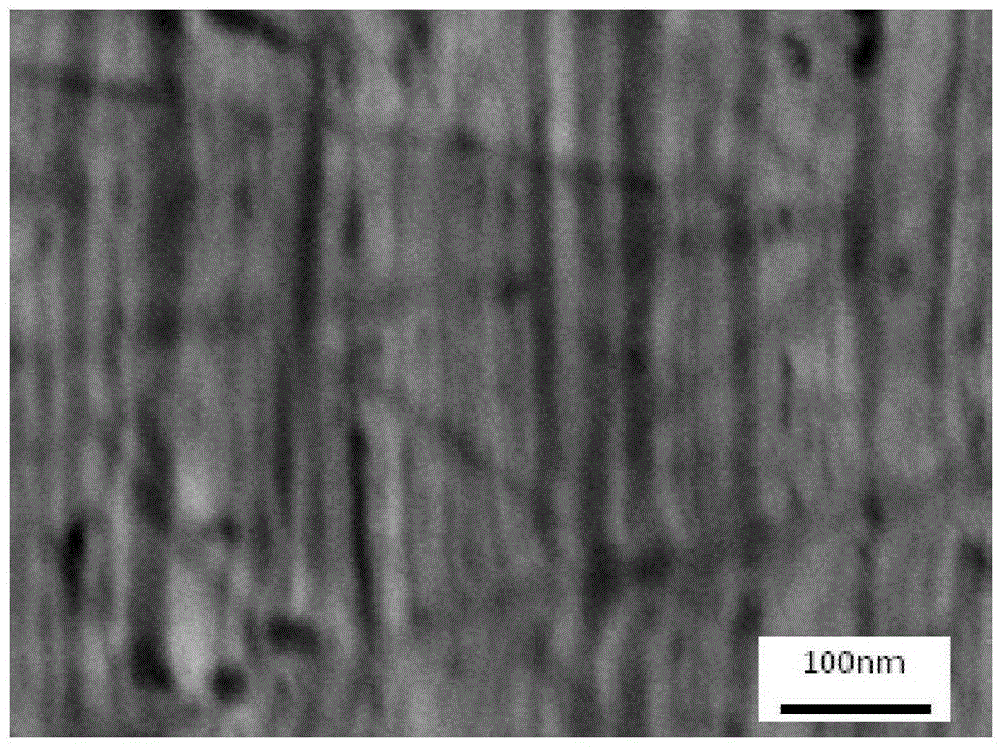

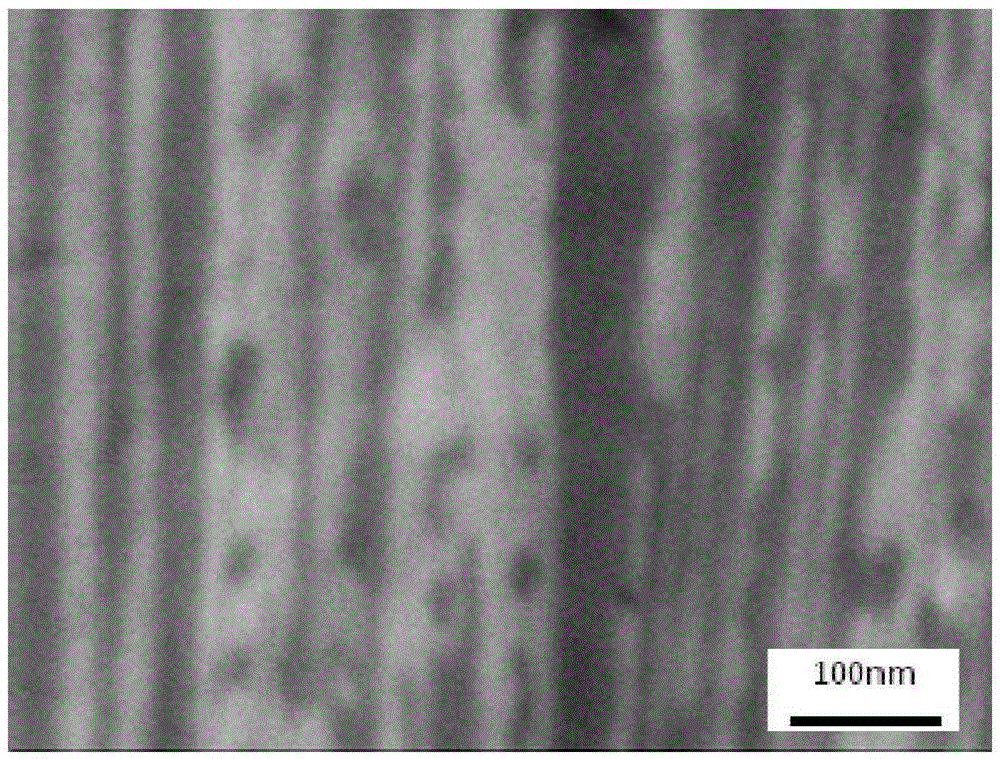

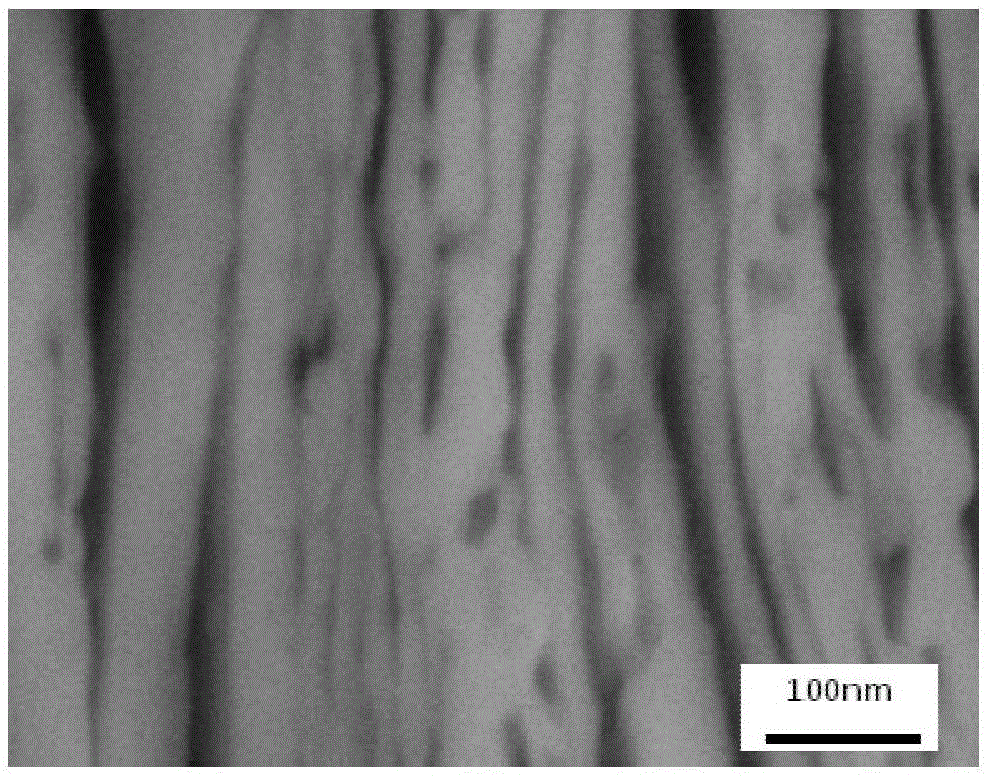

Image

Examples

Embodiment 1

[0046] The method for preparing nano-scale silver-nickel multilayer metal matrix composite material by combining with magnetic field heat treatment includes the following steps:

[0047] Step 1. Pretreatment of the substrate:

[0048] (1) The substrate is silver and nickel;

[0049] Among them, the substrate thickness is 0.05mm, the number of substrates is 20 silver substrates and 20 nickel substrates;

[0050] (2) Anneal the substrate under vacuum: the vacuum degree is 10*10 -2 Pa, the annealing temperature of the silver substrate is 400℃, and the annealing time is 30min; the annealing temperature of the nickel substrate is 700℃, and the annealing time is 60min; the internal stress of each substrate is removed after annealing;

[0051] (3) Clean both sides of the substrate, polish, descaling, clean the surface with acetone to remove oily impurities, and then cut the cuboid, where the length and width of each substrate after cutting are equal, and the thickness requirements of each subs...

Embodiment 2

[0077] The method for preparing nano-scale silver-nickel multilayer metal matrix composite material by combining with magnetic field heat treatment includes the following steps:

[0078] Step 1. Pretreatment of the substrate:

[0079] (1) The substrate is silver and nickel;

[0080] Among them, the substrate thickness is 0.1mm, the number of substrates is 10 silver substrates and 10 nickel substrates;

[0081] (2) Anneal the substrate under the protection of high-purity argon: the annealing temperature of the silver substrate is 450℃, and the annealing time is 20min; the annealing temperature of the nickel substrate is 600℃, and the annealing time is 90min; after annealing treatment Remove the internal stress of each substrate;

[0082] (3) Clean both sides of the substrate, polish, descaling, clean the surface with acetone to remove oily impurities, and then cut the cuboid, where the length and width of each substrate after cutting are equal, and the thickness requirements of each sub...

Embodiment 3

[0108] The method for preparing nano-scale copper-iron multilayer metal matrix composite material by combining with magnetic field heat treatment includes the following steps:

[0109] Step 1. Pretreatment of the substrate:

[0110] (1) The substrate is copper and iron;

[0111] Among them, the substrate thickness is 0.1mm, the number of substrates is 10 copper substrates and 10 iron substrates;

[0112] (2) Anneal the substrate under vacuum: the vacuum degree is 10*10 -2 Pa, the annealing temperature of the copper substrate is 400°C, and the annealing time is 40min; the annealing temperature of the iron substrate is 500°C, and the annealing time is 60min; the internal stress of each substrate is removed after annealing;

[0113] (3) Clean both sides of the substrate, polish, descaling, clean the surface with acetone to remove oily impurities, and then cut the cuboid, where the length and width of each substrate after cutting are equal, and the thickness requirements of each substrate a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com