Modified lithium manganese phosphate composite anode material and preparation method thereof

A composite positive electrode material, lithium manganese phosphate technology, applied in battery electrodes, electrical components, electrochemical generators, etc., can solve the problems of poor conductivity and poor rate performance, and achieve high specific capacity, excellent rate performance, and uniform dispersion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Take 0.1molLiMnPO 4 , 4g glucose, the LiMnPO 4 powder, NH 4 h 2 PO 4 , NaF and V 2 o 5 After weighing according to the mass ratio of the substance as 85:30:45:15, add it into the zirconia ball mill tank together with glucose, the mass ratio of the ball to material is 20:1, add 60ml of absolute ethanol, and pre-grind and mix at 300r / min for 0.5 hours Finally, high-energy ball milling at a speed of 400r / min for 2 hours to obtain a uniformly dispersed precursor mixture;

[0038] Add 50ml of deionized water to the above mixture, and perform high-energy ball milling at a speed of 400r / min for 3 hours, due to NH 4 h 2 PO 4 Dissolving self-adaptive regulation system is weakly acidic, mechanically activated V 2 o 5 Dissolving into gel and heteropoly acidification to obtain the lithium manganese phosphate / vanadium-containing colloidal precursor, placing the colloid in an 80°C blast drying oven for 24 hours, and grinding in a ball mill; the above-mentioned lithium manga...

Embodiment 2

[0040] Take 0.1molLiMnPO 4 , 3g sucrose, LiMnPO 4 powder and NaH 2 PO 4 After weighing according to the mass ratio of 80:20, add sucrose into the zirconia ball mill tank, the mass ratio of ball to material is 20:1, add 50ml of absolute ethanol, and high-energy ball mill at 400r / min for 2 hours to obtain dispersion Uniform precursor mixture; add 100ml deionized water to the above mixture, and LiMnPO 4 V 2 o 5 Quickly add to the above mixture, and high-energy ball milling at a speed of 400r / min for 3 hours to obtain the lithium manganese phosphate / vanadium-containing colloid precursor, dry the colloid in a blast drying oven at 80°C for 36 hours, and grind it by ball milling;

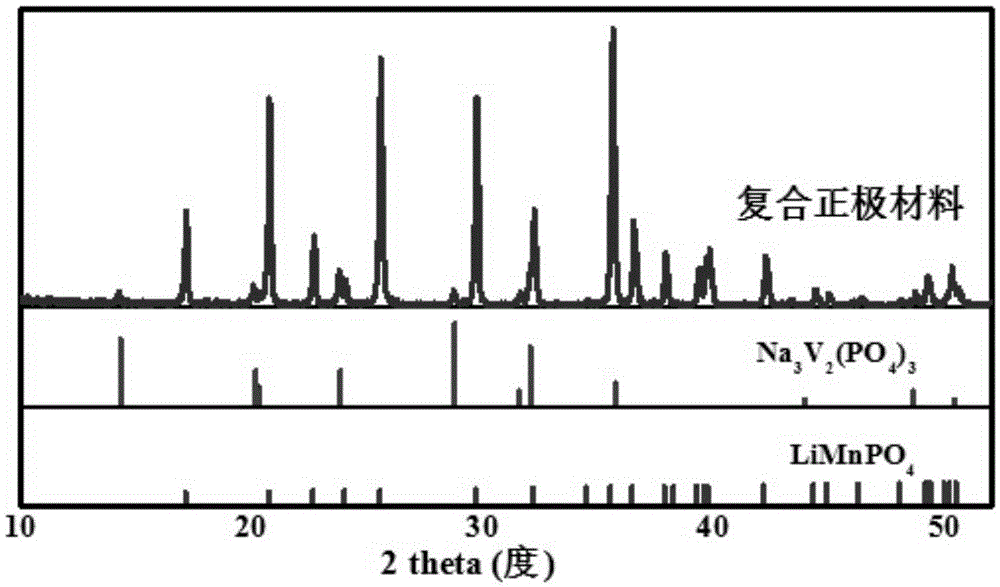

[0041] The above-mentioned lithium manganese phosphate / vanadium-containing colloidal precursor was sintered at 650 °C for 8 hours in a pure argon atmosphere to obtain 0.8LiMnPO 4 0.2Na 3 V 2 (PO 4 ) 3 / C composite material, XRD detects that this material has a two-phase composite structure (seein...

Embodiment 3

[0043] Take 0.1molLiMnPO 4 , 2g polyvinyl alcohol, the LiMnPO 4 powder, 85% concentrated phosphoric acid, V 2 o 5 And disodium edetate, ammonium fluoride by LiMnPO 4 :V 2 o 5 :H 3 PO 4 : EDTA-2Na, NH 4 The molar ratio of F substances is 95:5:10:7.5:15. After weighing, add polyvinyl alcohol into the zirconia ball milling tank. The mass ratio of ball to material is 20:1. After milling and mixing for 0.5 hours, then high-energy ball milling at a speed of 400r / min for 2 hours to obtain a uniformly dispersed precursor mixture; add 50ml of deionized water to the above mixture, 4 Add oxalic acid at a molar ratio of 15:95, and high-energy ball mill at a speed of 400r / min for 2 hours to obtain the lithium manganese phosphate / vanadium-containing colloidal precursor. The colloid is dried in a blast drying oven at 80°C for 20 hours, and ball milled to fineness; The lithium manganese phosphate / vanadium-containing colloidal precursor was sintered at 600 °C for 4 hours in a pure arg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com