Full-optical fiber laser interference lithography equipment and method thereof

A laser interference lithography, all-fiber technology, applied in the field of lithography, can solve the problems of interference pattern quality degradation, laser perturbation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Reference will now be made in detail to embodiments of the invention, examples of which are illustrated in the accompanying drawings, wherein like numerals refer to like elements throughout. The following embodiments will be described by referring to the figures in order to explain the present invention.

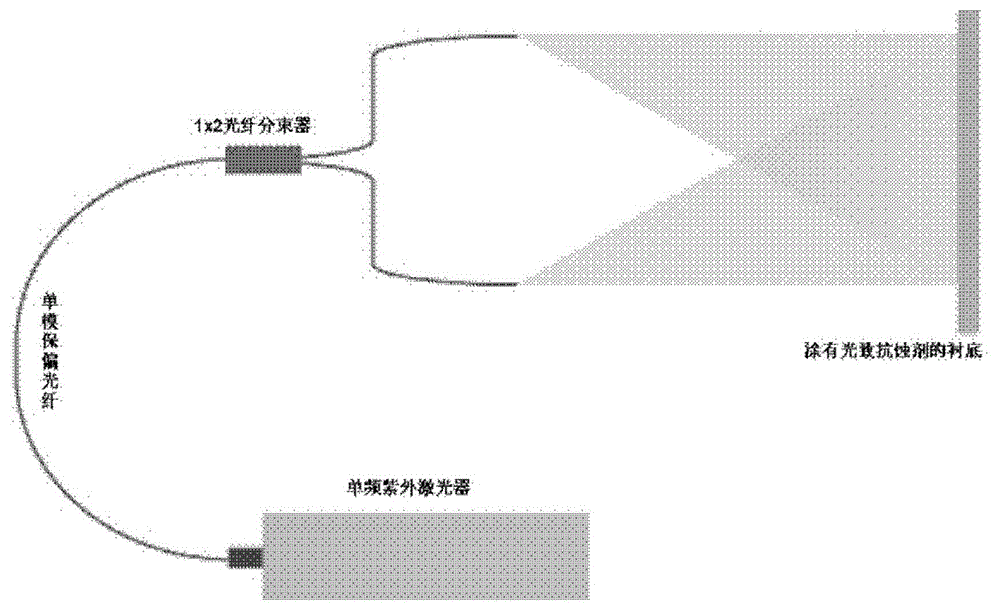

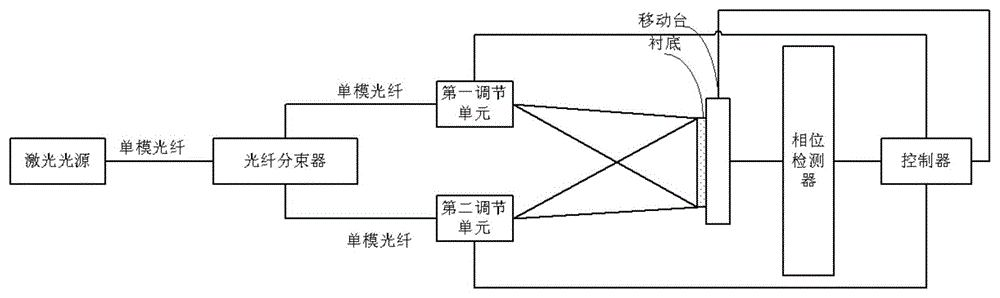

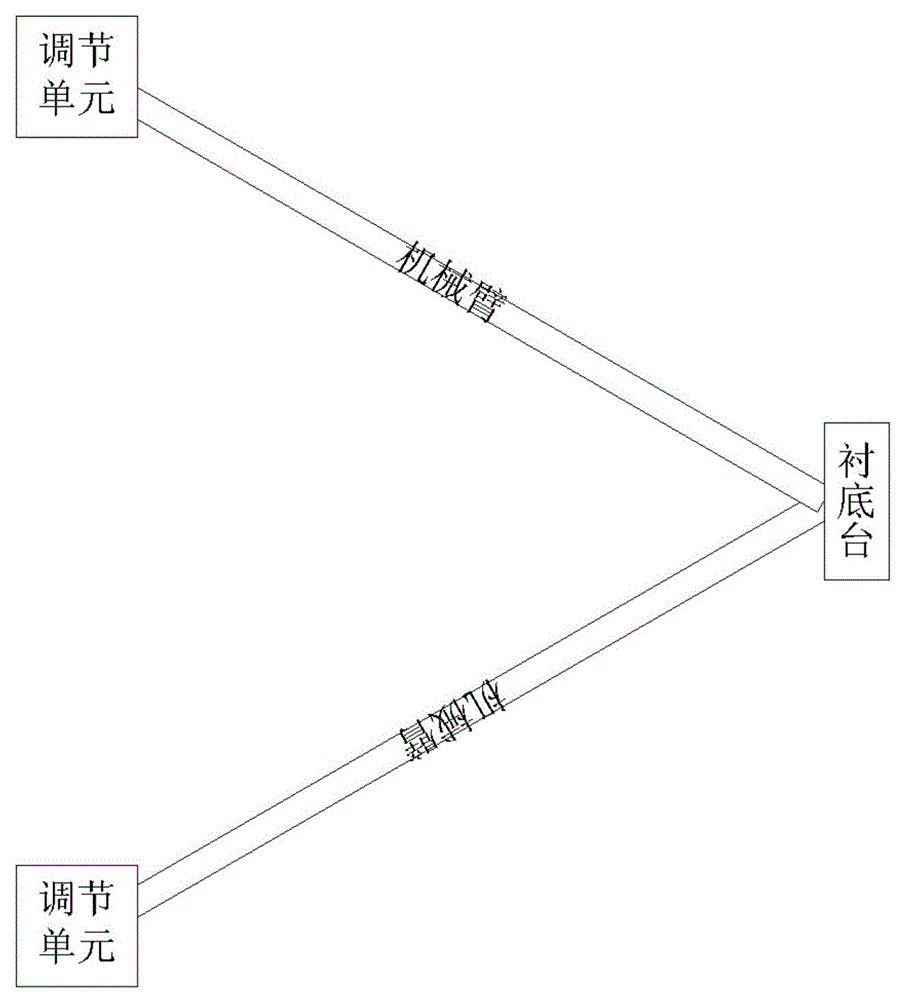

[0034] figure 1 The principle diagram of the all-fiber interference lithography system proposed by the present invention is schematically illustrated. The laser beam output from a 405nm single-frequency UV laser is coupled into a single-mode polarization-maintaining fiber (PMF). The PMF is connected to a 1x2 fiber optic beam splitter to obtain two laser beams with approximately equal intensities. The end face of the output fiber connected to the fiber splitter is directed towards the photoresist-coated substrate. Since a single-mode fiber with a small core diameter essentially behaves as a spatial fiber, it is preferable to obtain a circular Gaussian beam when emit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com