Thermal treatment method of 3D printing thin-walled part with AlSi10Mg as substrate and 3D printing thin-walled part

A heat treatment method and 3D printing technology, applied in the field of aluminum alloy heat treatment, can solve the problems of large deformation of thin-walled parts, and achieve the effects of simple and easy heat treatment process, guaranteed product quality, and small changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

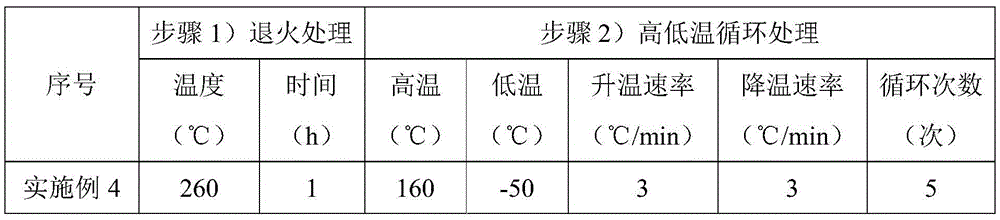

[0023] The heat treatment method of the 3D printing thin-walled parts with AlSi10Mg as the substrate of the present embodiment comprises the following steps:

[0024] 1) Anneal the AlSi10Mg thin-walled parts obtained by 3D printing. The annealing temperature is 260°C, the holding time is 4h, and air cooling;

[0025] 2) The thin-walled parts are subjected to high and low temperature cycle treatment in the high and low temperature range of high temperature of 160 °C and low temperature of -50 °C; first, the thin-walled parts are heated to 160 °C, kept for 4 hours, and cooled at a rate of 3 °C / min to -50°C, hold for 2 hours, then raise the temperature to 160°C at a rate of 3°C / min, hold for 4 hours, and complete one cycle; continue for 6 cycles, air-cool, and you are ready.

Embodiment 2

[0027] The heat treatment method of the 3D printing thin-walled parts with AlSi10Mg as the substrate of the present embodiment comprises the following steps:

[0028] 1) Anneal the AlSi10Mg thin-walled parts obtained by 3D printing. The annealing temperature is 360°C, the holding time is 1h, and air cooling;

[0029] 2) The thin-walled parts are subjected to high and low temperature cycle treatment in the high and low temperature range of high temperature of 160 °C and low temperature of -50 °C; first, the thin-walled parts are heated to 190 °C, kept for 2 hours, and cooled at a rate of 10 °C / min to -60°C, hold for 2 hours, then raise the temperature to 190°C at a rate of 10°C / min, hold for 2 hours, and complete a cycle; continue for 7 cycles, air-cool, and you are ready.

Embodiment 3

[0031] The heat treatment method of the 3D printing thin-walled parts with AlSi10Mg as the substrate of the present embodiment comprises the following steps:

[0032] 1) Anneal the AlSi10Mg thin-walled parts obtained by 3D printing. The annealing temperature is 320°C, the holding time is 3h, and air cooling;

[0033] 2) The thin-walled parts are subjected to high and low temperature cycle treatment in the high and low temperature range of high temperature of 180 °C and low temperature of -60 °C; firstly, the thin-walled parts are heated to 180 °C, kept for 2 hours, and cooled at a rate of 3 °C / min to -60°C, hold for 3 hours, then raise the temperature to 180°C at a rate of 3°C / min, hold for 2 hours, and complete one cycle; continue for 5 cycles, air-cool, and you are ready.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com