Rolling method of 6061 aluminum alloy ring part with ultra-large diameter and special-shaped section

A special-shaped cross-section, super-large diameter technology, applied in the field of ring rolling, can solve the problems of aluminum alloy rings that cannot be rolled, and achieve the effects of uniform internal structure, high material utilization rate, and complete streamlines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

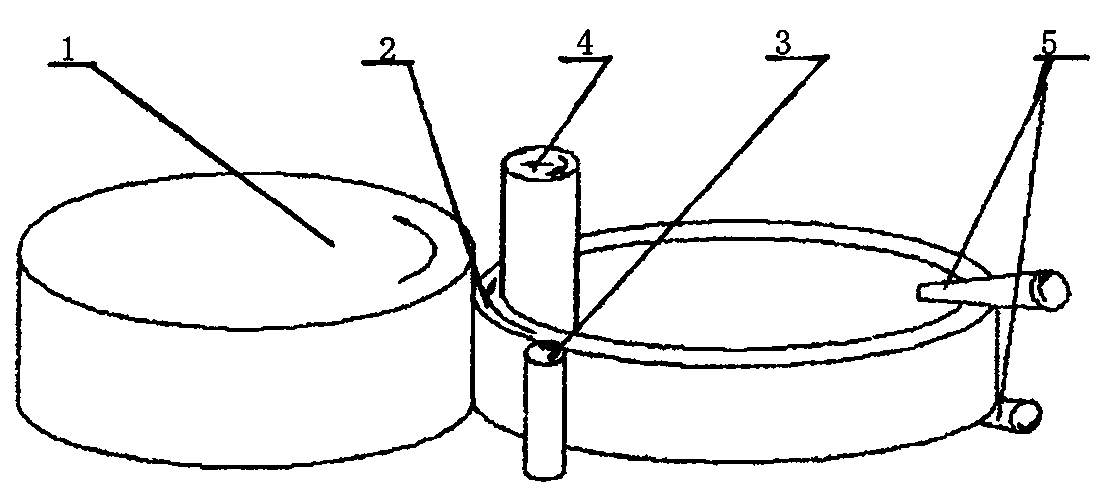

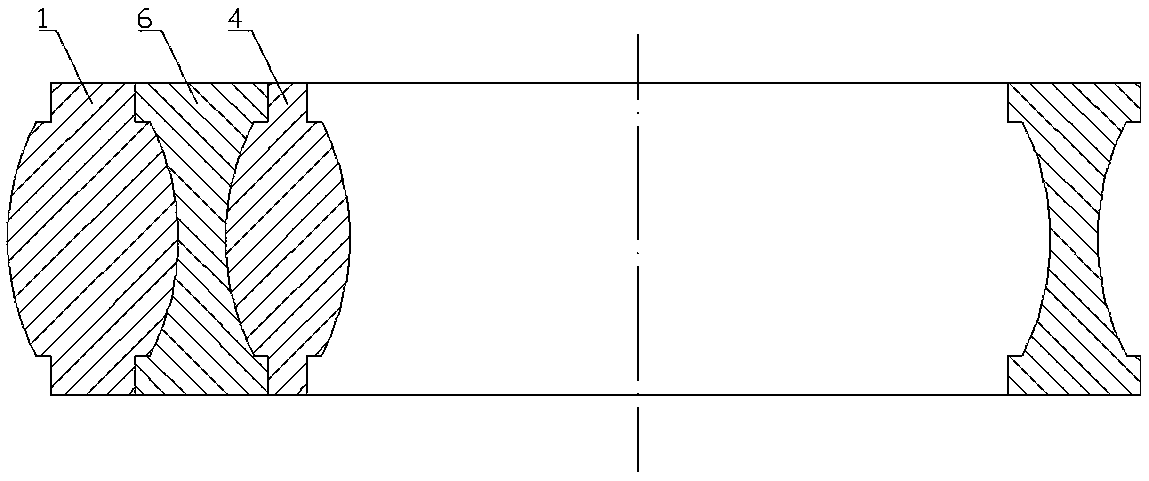

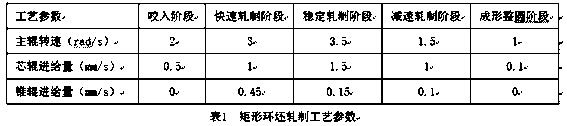

[0026] A rolling method of a super-large-diameter 6061 aluminum alloy special-shaped cross-section ring, comprising the following steps:

[0027] (1) Blanking, the height-to-diameter ratio of the blanking material is less than 2.5, and the 6061 aluminum alloy ingot is sawed into ingots as required. The ingot size is 1150mm in diameter and 2800mm in height;

[0028] (2) Put the ingot into the electric furnace to heat up, the furnace temperature is controlled at 470°C, and the holding time is 22 hours;

[0029] (3) Free forging, upsetting, punching, and bracket hole expansion of 6061 aluminum alloy ingots;

[0030] First, the heated and heat-preserved ingot is upset and forged into a round cake-shaped billet, and then the billet is punched. The inner diameter of the punching hole is 500mm. After the punching is completed, the temperature is raised to 470°C and kept for 5 hours. Finally, the billet is horse-framed. Reaming, preparing a ring blank with an outer diameter of 5000mm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com