Reinforced PP/recycled PET bottle flake alloy for vehicle fan wind wheels, and preparation method thereof

A technology of fans and bottle flakes, which is applied in the field of alloy composite materials and its preparation, can solve the problems of application limitations, difficulty in meeting the heat resistance, high strength, and high dynamic balance of automobile fan wheels, and achieve the compounding process and processing process Simplicity, realization of high value-added utilization, and the effect of expanding the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

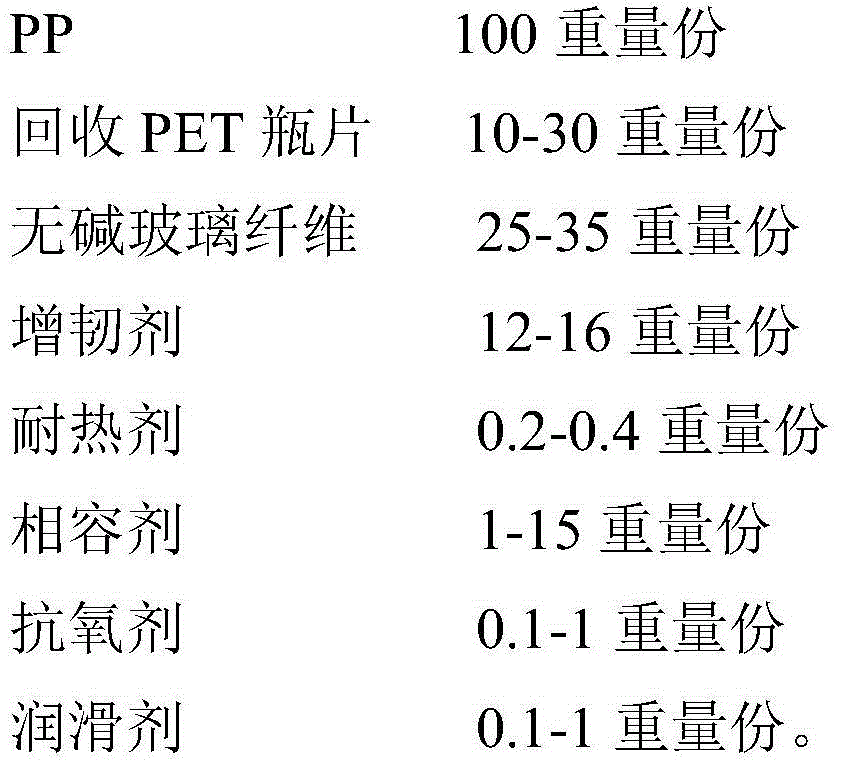

[0042] A kind of preparation method of reinforced PP / recycled PET bottle flake alloy for automobile fan wind wheel, comprises the following steps:

[0043] 1) Dry the recovered PET bottle flakes in a vacuum oven. Drying is preferably divided into two stages, wherein the first stage is dried at a temperature of 75°C-80°C for 3h-5h, preferably 3.5h-4.5h; the second stage is at a temperature of 120°C-140°C Dry for 4h-10h, preferably 4h-6h.

[0044] 2) Mix PP, recycled PET bottle flakes, toughening agent, heat-resistant agent, compatibilizer, antioxidant and lubricant in proportion for 5-10 minutes to make a mixture.

[0045] 3) Add the mixture into the twin-screw extruder through the main feeding port of the twin-screw extruder, and at the same time of melting and extruding, add alkali-free glass fiber from the side feeding device to melt and extrude, and the extruded material is cooled , air-dried, pelletized, and dried to obtain the composite material of the reinforced PP / recyc...

Embodiment 1

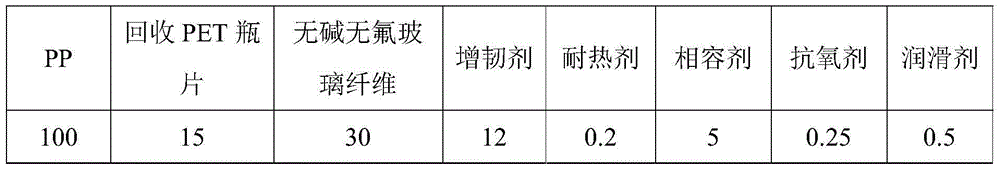

[0048] The composite material of reinforced PP / reclaimed PET bottle flake alloy for the wind wheel of automobile fan of the present invention, its composition is as shown in table 1:

[0049] Table 1: Unit (kg)

[0050]

[0051] Among them, the flexural modulus of PP reaches 2400MPa;

[0052] The intrinsic viscosity of recycled PET bottle flakes is 0.68dl / g;

[0053] Alkali-free and fluorine-free glass fiber is long fiber;

[0054] The toughening agent is POE-MAH graft copolymer, wherein the content of maleic anhydride accounts for 0.9% of the POE-MAH graft copolymer.

[0055] The compatibilizer is PP-MAH graft copolymer, wherein the content of maleic anhydride accounts for 0.9% of the PP-MAH graft copolymer.

[0056] The heat-resistant agent is an aroyl compound N,N'-dicyclohexyl-2,6-naphthalenediamide;

[0057] The antioxidant is antioxidant 1010 and antioxidant DLTP, the ratio of the two is 1:1;

Embodiment 2

[0060] The composite material of reinforced PP / reclaimed PET bottle flake alloy for the wind wheel of automobile fan of the present invention, its composition is as shown in table 2:

[0061] Table 2: Unit (kg)

[0062]

[0063] Among them, the flexural modulus of PP reaches 2400MPa;

[0064] The intrinsic viscosity of recycled PET bottle flakes is 0.68dl / g;

[0065] Alkali-free and fluorine-free glass fibers are short fibers with a diameter of 13 microns and a length of 4.5mm;

[0066] The toughening agent is POE-MAH graft copolymer, wherein the content of maleic anhydride accounts for 0.8% of the POE-MAH graft copolymer.

[0067] The compatibilizer is PP-MAH graft copolymer, wherein the content of maleic anhydride accounts for 1.0% of the PP-MAH graft copolymer.

[0068] The heat-resistant agent is an aroyl compound N,N'-dicyclohexyl-2,6-naphthalenediamide;

[0069] The antioxidant is antioxidant 1010 and antioxidant DLTP, the ratio of the two is 1:1;

[0070] The lu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural modulus | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com