Hydrophobic associated polymer and preparing method thereof

A hydrophobic association, polymer technology, applied in the field of polymers, can solve problems such as damage to the formation environment, intolerance to salt, performance degradation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

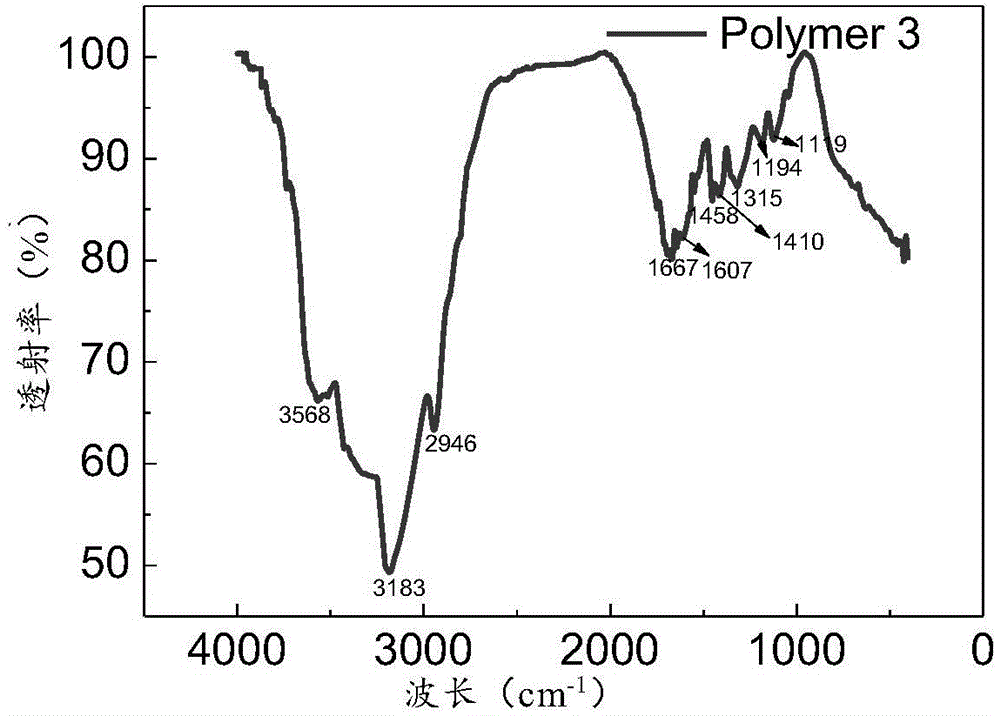

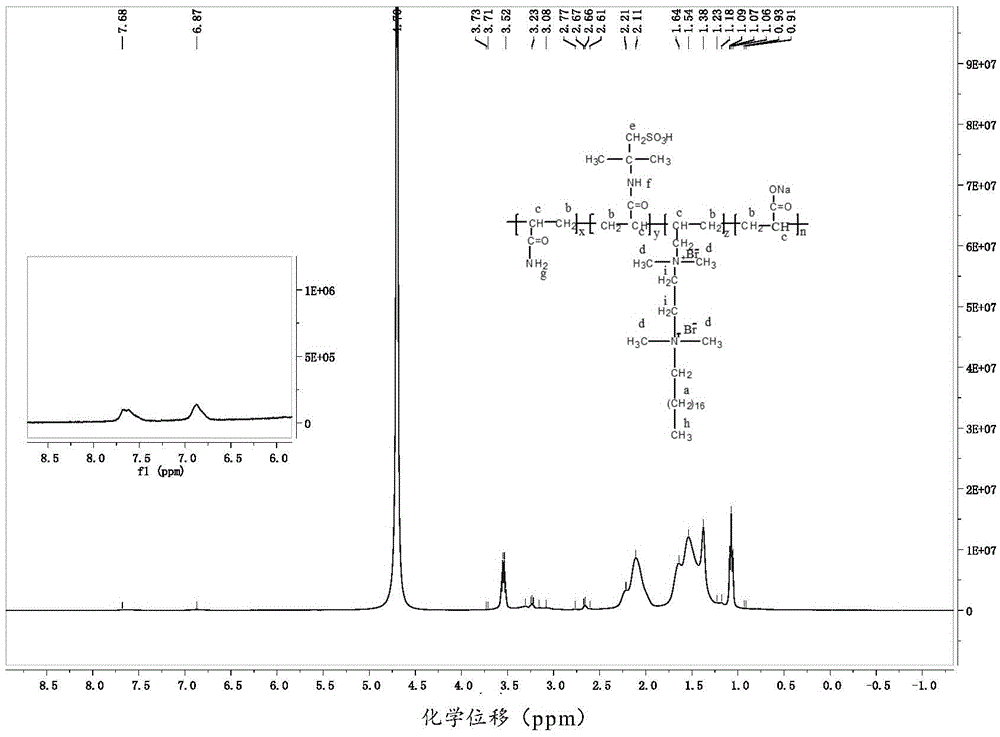

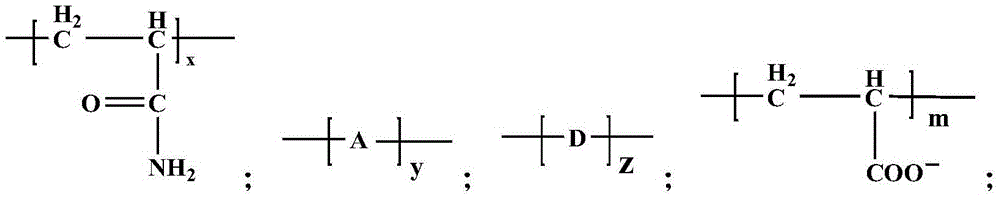

[0036] The present invention also provides a method for preparing the above-mentioned hydrophobic association polymer. The method is to introduce sodium acrylate in the form of subsequent hydrolysis, including: under the action of an initiator, acrylamide monomer, hydrophobic monomer and functional monomer Copolymerization reaction, after hydrolysis to obtain a hydrophobic association polymer; the hydrophobic monomer is selected from allyl alkyl quaternary ammonium salt, acrylamide alkyl sulfonic acid and its sulfonate, alkylphenol polyoxyethylene acrylate and acrylic acid One or more of polyoxyethylene alkyl esters; the number of carbon atoms of the alkyl group in the allyl alkyl quaternary ammonium salt and acrylamide alkyl sulfonic acid and its sulfonate is independently less than or equal to 20; The functional monomer is selected from one or more of sulfonic acid derivatives containing terminal alkenyl groups and sulfonate derivatives thereof, and heterocyclic derivatives c...

Embodiment 1

[0057] Acrylamide monomer, functional monomer 2-acrylamide-2-sodium methylpropane sulfonate and hydrophobic monomer octadecyl allyl dibromide tetramethylethylenediammonium are in the mole ratio of 85:14.2:0.8 Add to a 5000mL beaker and dissolve with pure water to prepare a mixed solution with a total monomer mass concentration of 25%. Add sodium dodecylbenzenesulfonate at a ratio of 10 times the molar concentration of the hydrophobic monomer and stir well. , then put the beaker into a 30°C water bath and keep warm until the solution temperature is 30°C, add ammonium persulfate and sodium bisulfite composite initiator to initiate polymerization, wherein the mass ratio of ammonium persulfate to sodium bisulfite is 5:4, over The amount of ammonium sulfate added is 0.1% of the monomer mass; the polymerization reaction is carried out under adiabatic conditions, and a thermometer is inserted in the center of the reaction system to monitor the progress of the polymerization reaction. ...

Embodiment 2

[0061] Acrylamide monomer, sodium acrylate monomer, functional monomer 2-acrylamide-2-sodium methyl propane sulfonate and hydrophobic monomer octadecyl allyl dibromide tetramethylethylene diammonium according to 69: The molar ratio of 16:14.2:0.8 (the ratio of the four) is added to deionized water, fully dissolved, and this solution is used as the water phase; add a compound with a mass ratio of Span-80:Tween-20=8:2 to kerosene The emulsifier is stirred until fully dissolved, and as the oil phase, the additive amount of the compound emulsifier is 15% to 18% of the total system mass. Under high-speed stirring, the aqueous phase solution was added to the oil phase, emulsified for 20 min, and transferred to a 5000 mL beaker, with the total mass concentration of the monomer being 25%. Add ammonium persulfate and sodium bisulfite composite initiator when the emulsion is kept at 30°C to initiate polymerization, wherein the mass ratio of ammonium persulfate to sodium bisulfite is 5:4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com