Method for preparing nanometer lanthanum oxide coating on metal carrier

A technology of nano-lanthanum oxide and metal carrier, which is applied in the direction of chemical instruments and methods, separation methods, chemical/physical processes, etc. It can solve the problem of affecting the transformation effect and service life of post-processing devices, the easy agglomeration of nano-materials, and the reduction of specific surface area, etc. problem, to achieve the effect of benefiting conversion efficiency and reaction rate, improving catalytic ability, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

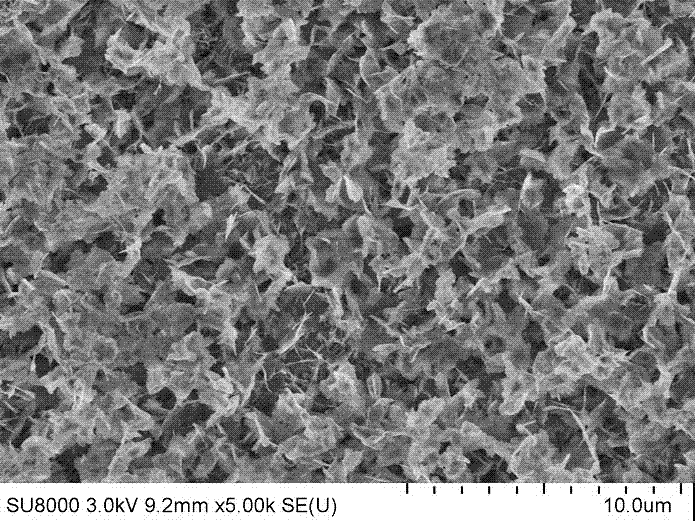

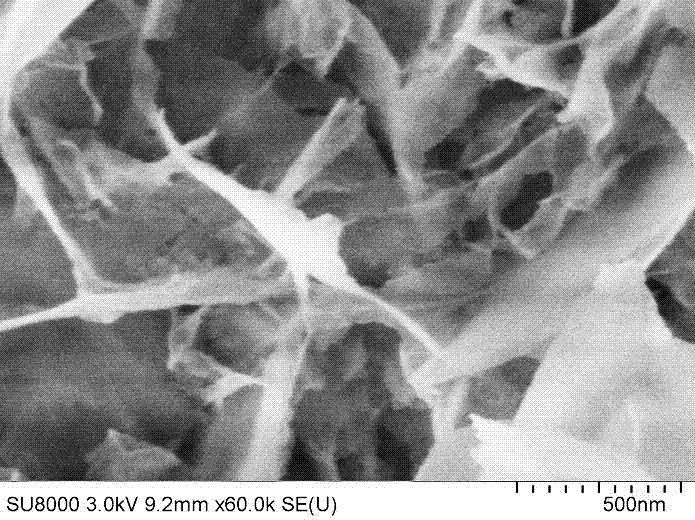

[0024] The metal foam carrier was used as the test object. Firstly, it is pretreated, and the technological process is electrochemical degreasing, electrochemical activation, and weak acid erosion. The parameters of the electrochemical degreasing process are shown in Table 1. Degrease the anode for 1min, then rinse it with clean water. The electroactivation process is to immerse the carrier in 50ml / L dilute sulfuric acid solution to maintain the activity of the carrier surface, and conduct the electrodeposition lanthanum oxide coating test within 10 minutes.

[0025]

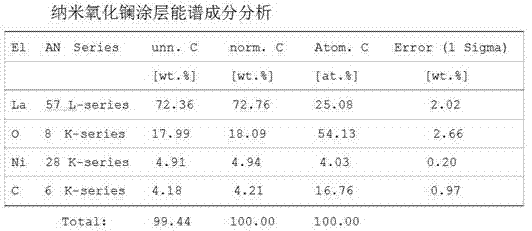

[0026]The composition of the plating solution used in the electrodeposition process is lanthanum sulfate 0.05mol / L, sodium sulfate 0.5mol / L, additive 1ml / L, ethanol 40% solvent, deionized water 60% solvent, and the temperature of the plating solution is room temperature. The above-mentioned pretreated carrier is put into the plating solution as an anode, and a stainless steel electrode is used as the cathod...

Embodiment 2

[0028] A metal fiber carrier was used as the test object. Firstly, it is pretreated, and the technological process is: electrochemical degreasing, electrochemical activation, and weak acid erosion. The parameters of the electrochemical degreasing process are shown in Table 1. Degrease the cathode for 3 minutes, then rinse it with clean water. The electroactivation process is to immerse the carrier in 50ml / L dilute sulfuric acid solution to maintain the activity of the carrier surface, and conduct the electrodeposition lanthanum oxide coating test within 10 minutes.

[0029] The composition of the plating solution used in the electrodeposition process is lanthanum nitrate 1mol / L, sodium sulfate 0.5mol / L, additive 8ml / L, ethanol 10% solvent, deionized water 90% solvent, and the temperature of the plating solution is 40°C. The above-mentioned pretreated carrier is put into the plating solution as a cathode, and the cathode adopts a glassy carbon electrode. Connect the pulse po...

Embodiment 3

[0031] The metal honeycomb carrier was used as the test object. Firstly, it is pretreated, and the technological process is electrochemical degreasing, electrochemical activation, and weak acid erosion. Among them, the electrochemical degreasing process parameters are as follows: Figure 4 shown. Degrease the cathode and anode for 3 minutes and 1 minute respectively, and then rinse them with clean water. The electroactivation process is to immerse the carrier in 50ml / L dilute sulfuric acid solution to maintain the activity of the carrier surface, and conduct the electrodeposition lanthanum oxide coating test within 10 minutes.

[0032] The composition of the plating solution used in the electrodeposition process is lanthanum acetate 0.1mol / L, sodium sulfate 0.5mol / L, additive 2ml / L, ethanol 60% solvent, deionized water 40% solvent, and the temperature of the plating solution is room temperature. The above-mentioned pretreated carrier is put into the plating solution as a ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com