Method for treating copper concentrate through improved side blowing molten pool melting furnace

A melting pool smelting furnace and copper concentrate technology, applied in furnaces, electric furnaces, rotary drum furnaces, etc., can solve problems such as endangering production safety and personal safety, excessive SO2, and foamy slag generation, and achieve less labor quota and lower production costs Low, compact flow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

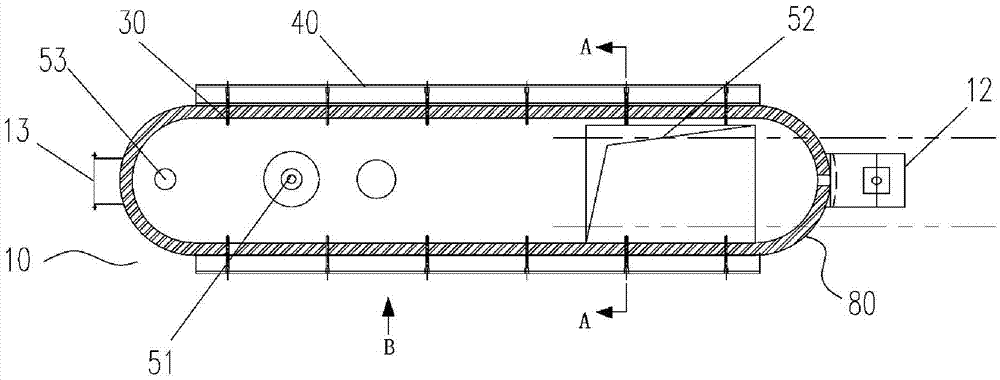

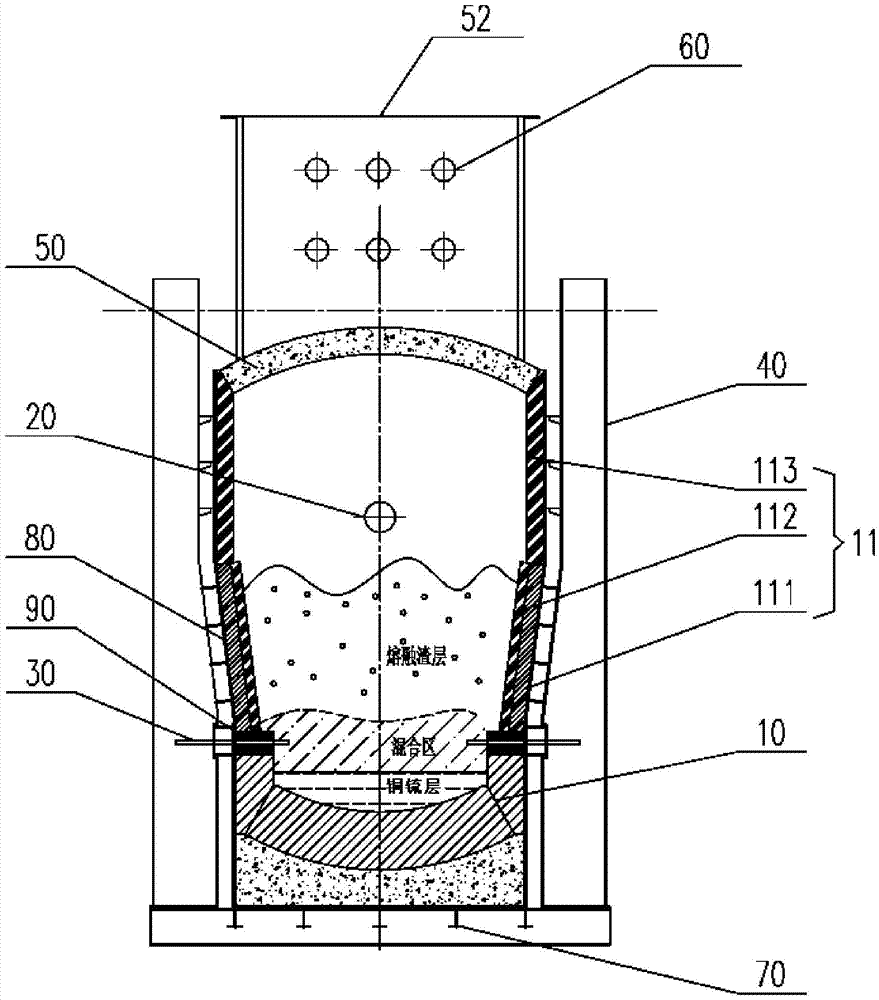

[0050]One embodiment of the present invention provides a method for processing copper concentrate using an improved side-blowing molten pool smelting furnace. The multi-channel spray guns 30 installed on both sides of the molten pool smelting furnace spray oxygen-enriched gas and fuel into the molten pool mixing zone at a flow rate of 180m / s-280m / s, so that the materials in the furnace undergo a molten pool smelting reaction and generate copper matte and Smelting slag; the above-mentioned melting pool mixing zone refers to the transition zone between the melting slag layer on the upper part of the melting pool and the copper matte layer on the lower part of the melting pool. The smelting slag ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com