Strength/toughness-modified urea formaldehyde resin foam thermal-insulation material and preparation method thereof

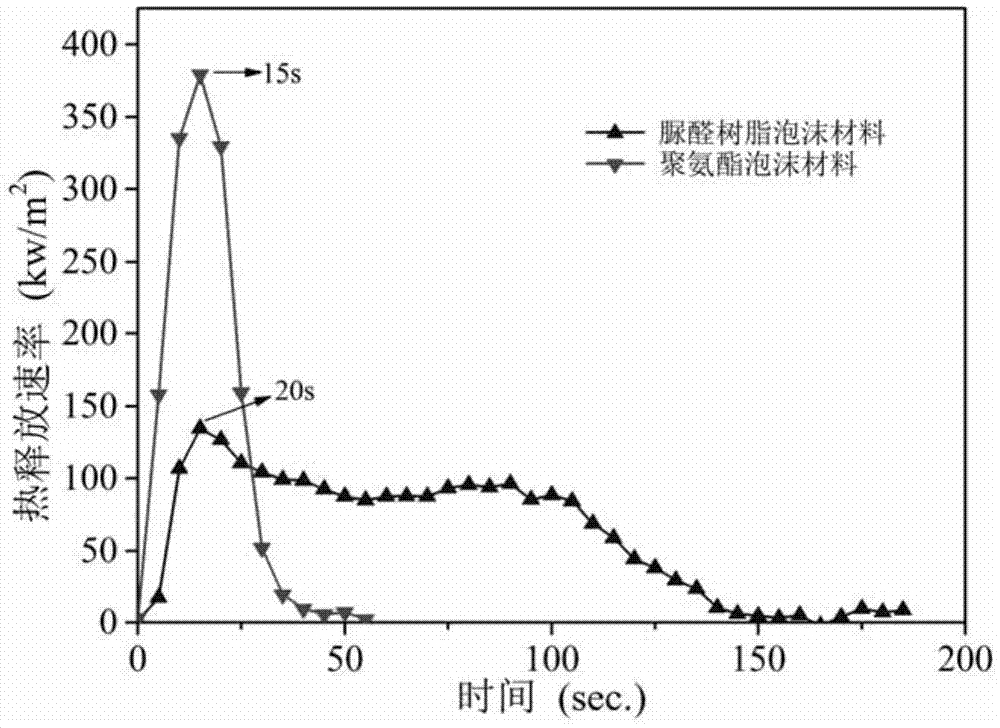

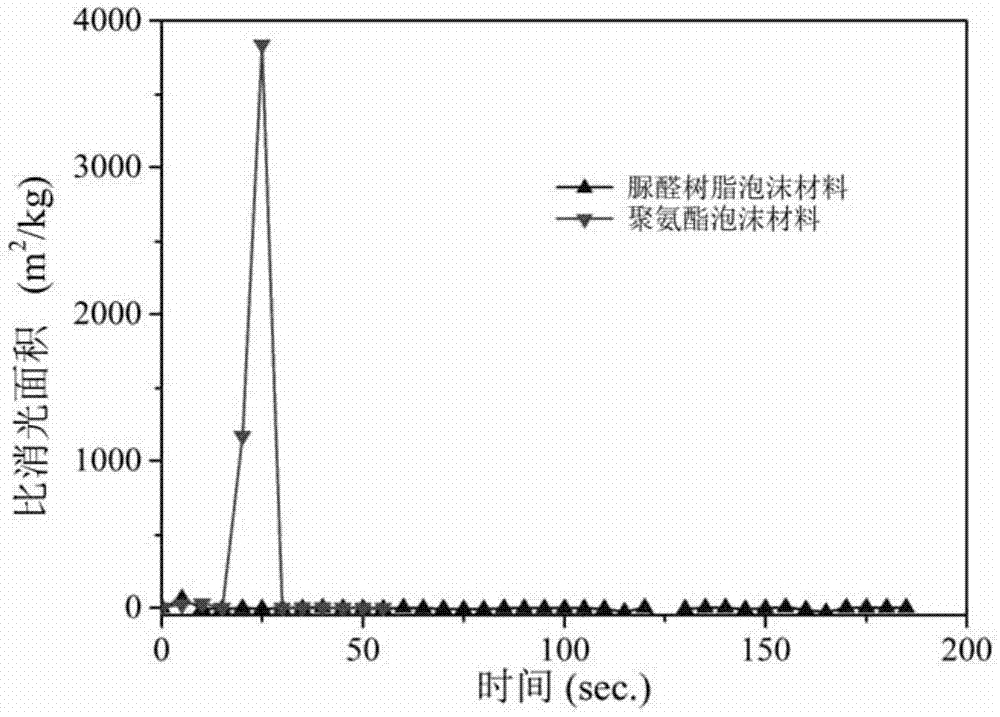

A technology of urea-formaldehyde resin foam and insulation materials, which is applied in the field of foam insulation materials, can solve the problems of high brittleness, easy slag drop, low strength, etc., and achieve the effects of improving compression strength, low cost, and good flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0038] Embodiment 1: The modified urea-formaldehyde resin foam insulation material in this embodiment is prepared from raw materials according to the following weight percentages:

[0039] Urea-formaldehyde resin: 91.24%; Foaming agent: 2.1%; Surfactant: 3.0%; Thickener: 0.46%; Curing agent: 1.2%; Modifier: 1.8%;

[0040] Wherein, surfactant is polyoxyethylene sorbitan monooleate (Tween-80); Thickener is: sodium carboxymethyl cellulose; Curing agent: mass fraction is 15% tartaric acid aqueous solution; Modified Agent: nano silicon dioxide.

[0041] The specific preparation method is as follows:

[0042] Step a. Stir urea-formaldehyde resin, n-hexane, and Tween-80 at room temperature at a speed of 300-400r / min until uniform (stirring takes 3-5min), then add nano-silica, and continue stirring for 3-5min , then add sodium carboxymethylcellulose, and then stir for 10 to 15 minutes at a stirring speed of 1400 to 1600 r / min; finally add tartaric acid solution, and continue stirrin...

specific Embodiment approach 2

[0051] Embodiment 2: The modified urea-formaldehyde resin foam insulation material in this embodiment is prepared from raw materials according to the following weight percentages:

[0052] Urea-formaldehyde resin: 89.7%; Foaming agent: 2.06%; Surfactant: 2.99%; Thickener: 0.45%; Curing agent: 1.2%; Modifier: 3.6%;

[0053] Wherein, surfactant is polyoxyethylene sorbitan monooleate (Tween-80); Thickener is: sodium carboxymethyl cellulose; Curing agent: mass fraction is 15% tartaric acid aqueous solution; Modified Agent: basalt fiber.

[0054] The specific preparation method is as follows:

[0055] Step a. Stir urea-formaldehyde resin, n-hexane, and Tween-80 at room temperature at a speed of 300-400 r / min until uniform (stirring takes 3-5 minutes), then add basalt fiber, continue stirring for 3-5 minutes, and then Add sodium carboxymethyl cellulose, and then stir for 10-15 minutes at a stirring speed of 1400-1600 r / min; finally add tartaric acid solution, and continue stirring...

specific Embodiment approach 3

[0064] Specific embodiment three: The modified urea-formaldehyde resin foam insulation material in this embodiment is prepared from raw materials according to the following weight percentages:

[0065] Urea-formaldehyde resin: 90.5%; Foaming agent: 2.08%; Surfactant: 3.02%; Thickener: 0.45%; Curing agent: 1.25%; Modifier: 2.7%;

[0066] Wherein, surfactant is polyoxyethylene sorbitan monooleate (Tween-80); Thickener is: sodium carboxymethyl cellulose; Curing agent: mass fraction is 15% tartaric acid aqueous solution; Modified Agent: polyvinyl acetate.

[0067] The specific preparation method is as follows:

[0068] Step a. Stir urea-formaldehyde resin, n-hexane, and Tween-80 at room temperature at a speed of 300-400r / min until uniform (stirring takes 3-5min), then add polyvinyl acetate, and continue stirring for 3-5min , then add sodium carboxymethylcellulose, and then stir for 10 to 15 minutes at a stirring speed of 1400 to 1600 r / min; finally add tartaric acid solution, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com