Method for manufacturing liquid-crystal display

A technology of a liquid crystal display device and a manufacturing method, applied in optics, instruments, nonlinear optics, etc., can solve problems such as damage to thin-film transistor elements, uneven display, poor foreign matter, etc., and achieve the effect of improving display quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] In Example 1, the main heating is performed twice at different temperatures in the above step (4), and between the first main heating (first main heating step) and the second main heating (second main heating step), Furthermore, when light irradiation (2nd light irradiation process) is performed to the said film which performed the 1st main heating. Hereinafter, the method of manufacturing the liquid crystal display device of Example 1 will be sequentially described.

[0053] (Structure of liquid crystal display device)

[0054] It is a liquid crystal display device with an electrode structure for the FFS mode, and the pretilt angle is 0°.

[0055] (Photo Alignment Film Material)

[0056] As the solid content, a polymer having a methacryloyl skeleton and containing a photoreactive cinnamate group in a side chain is used. As the solvent, a solvent obtained by mixing N-methyl-pyrrolidone and butyl cellosolve at a weight ratio of 50:50 was used. In addition, the solid content c...

Embodiment 2

[0091] Example 2 is a case where a liquid crystal material containing liquid crystal molecules having negative dielectric constant anisotropy is used in Example 1. The manufacturing method of the liquid crystal display device of Example 2 is the same as that of Example 1 except that the dielectric constant anisotropy of the liquid crystal molecules is different. Therefore, the description of the overlapping points is omitted.

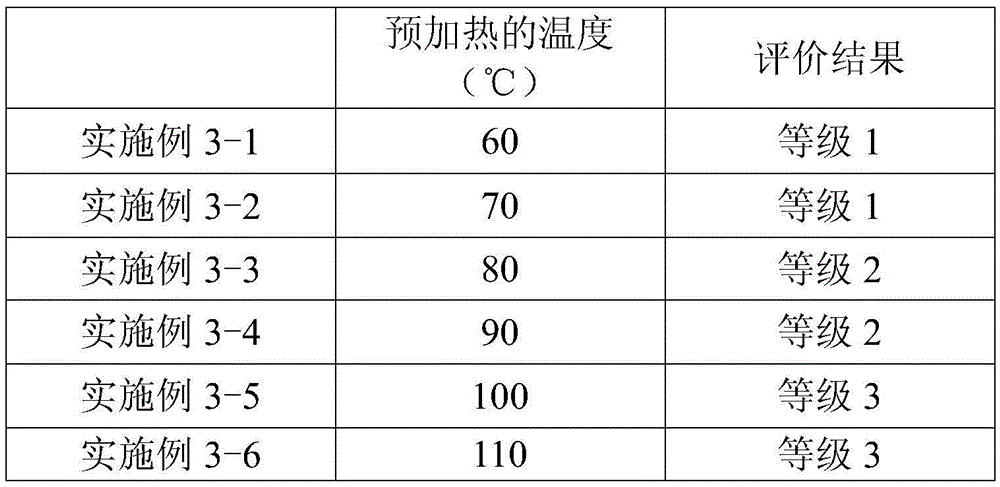

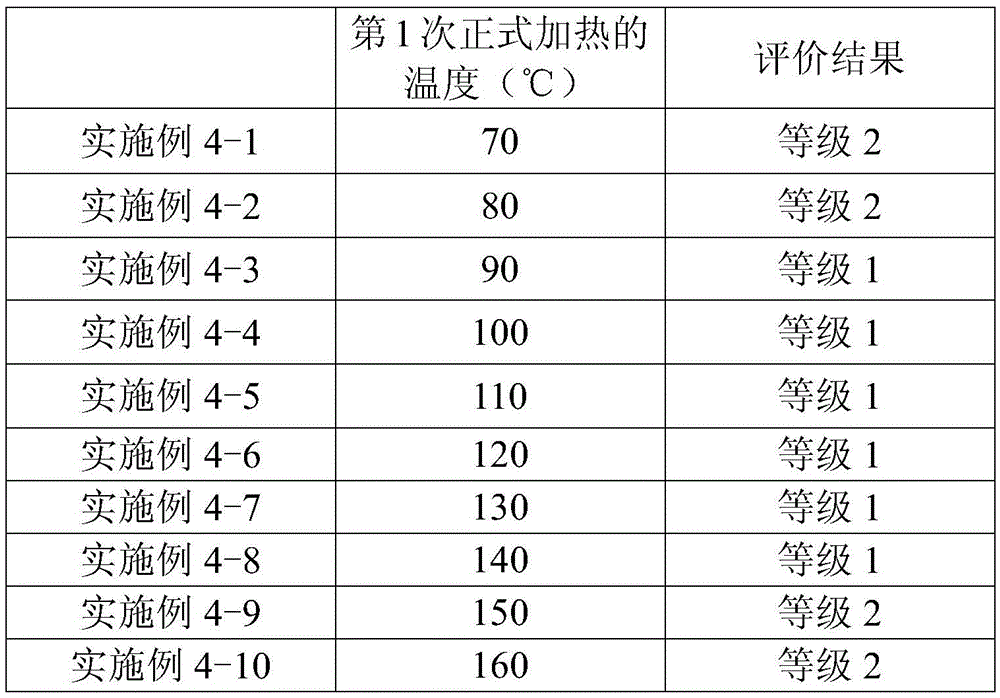

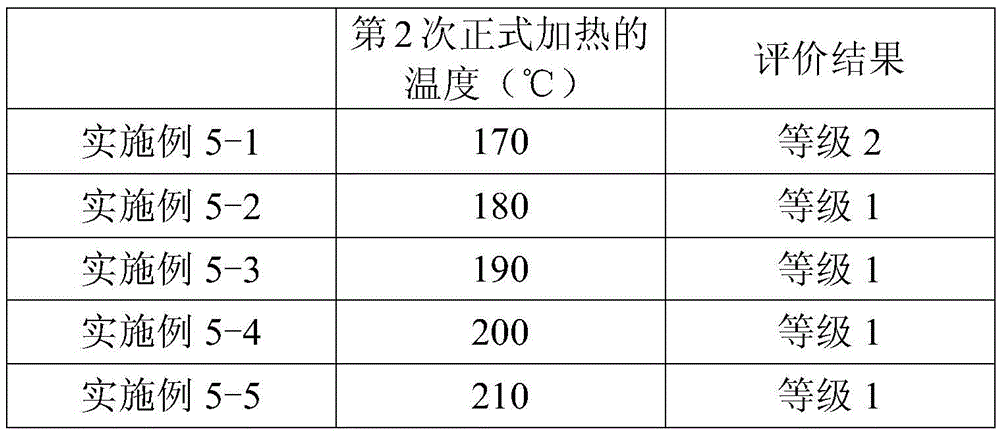

Embodiment 3-1

[0117] In Example 3-1, the main heating was performed twice at different temperatures in the above step (4). The method of manufacturing the liquid crystal display device of Example 3-1 will be sequentially described below.

[0118] (Structure of liquid crystal display device)

[0119] It is a liquid crystal display device with an electrode structure for the FFS mode, and the pretilt angle is 0°.

[0120] (Photo Alignment Film Material)

[0121] As the solid content, a polymer containing an azobenzene structure having photoreactivity is used. As the solvent, a solvent obtained by mixing N-methyl-pyrrolidone and butyl cellosolve at a weight ratio of 50:50 was used. In addition, the solid content concentration was 4% by weight. Here, the azophenyl group is a photofunctional group capable of photoisomerization.

[0122] (Process of forming a film of photo-alignment film material)

[0123] On two substrates, a film of a photo-alignment film material was formed by a spin coating method.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com