Circuit boards and their applications

A circuit board and circuit technology, applied in the field of electronics, can solve the problems of poor waterproof ability of circuit boards, high circuit defect rate, complex production process, etc., and achieve the effect of reducing the probability of circuit defects, reducing production processes, and reducing process difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

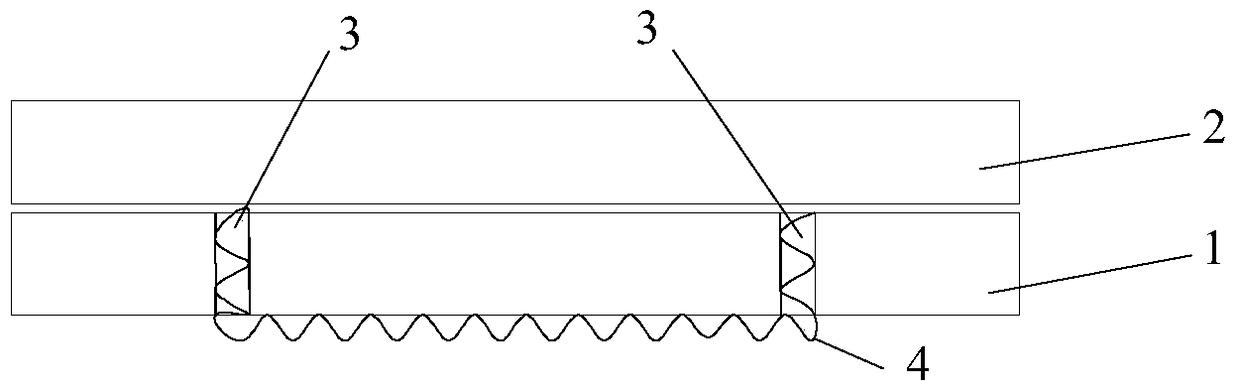

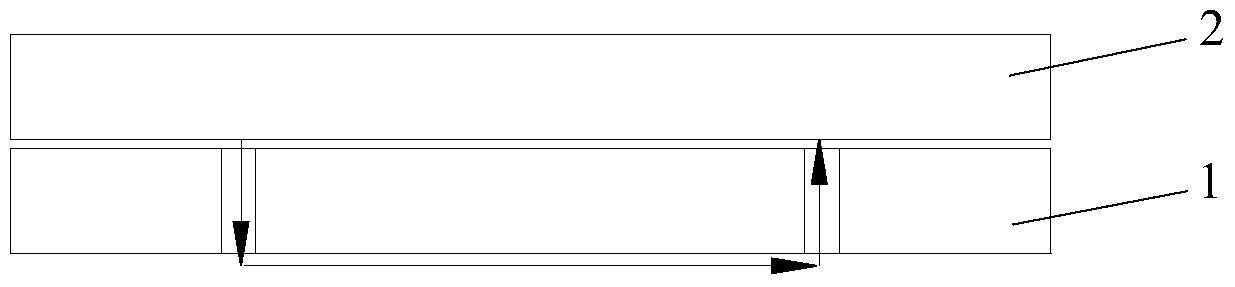

[0019] Such as figure 1 , the circuit board of the present invention comprises a substrate 1 and an etched metal circuit 2 positioned above the substrate 1, the substrate 1 is provided with at least one pair of through holes 3, the inside of the through holes 3 and the substrate between the two through holes 3 The bottom of the material is provided with a conductive coating 4, and the base material 1 and the etched metal circuit 2 form a conductive closed loop, such as figure 2 .

[0020] An etched metal circuit 2 is provided on one side of the substrate 1 to replace the traditional circuit formed by printing silver wires on the substrate 1. The conductive circuits are densely concentrated on the metal layer, which can reduce the probability of defects compared with the printed circuits. Improve the yield rate; by drilling the substrate 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com