Turning to multi-wire cutting method and equipment

A multi-wire cutting and multi-wire cutting machine technology, applied in the field of mechanical processing, can solve the problems of increased material turnover time and long time, and achieve the effects of improving product quality, reducing the probability of defects, and shortening material turnover time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

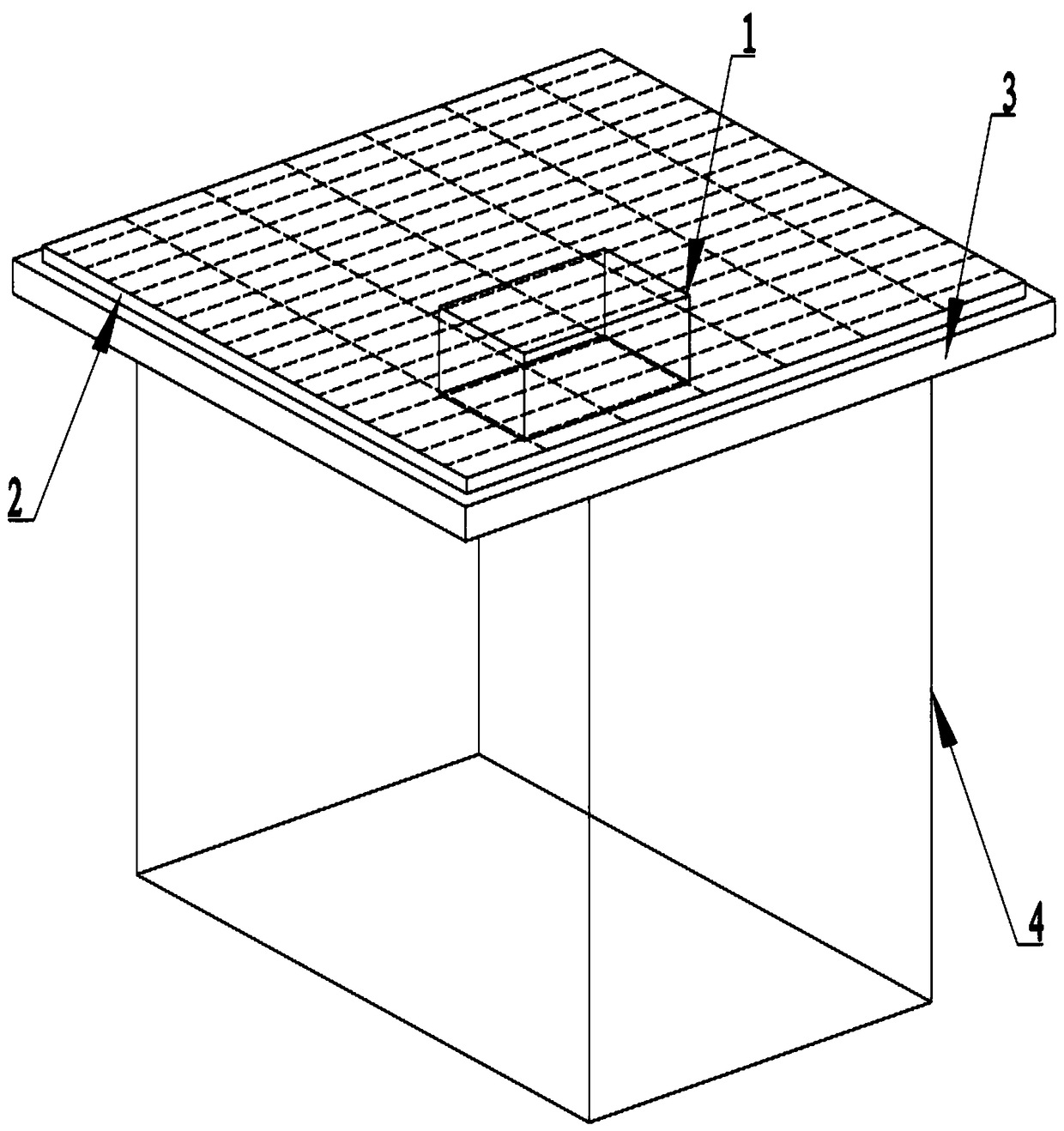

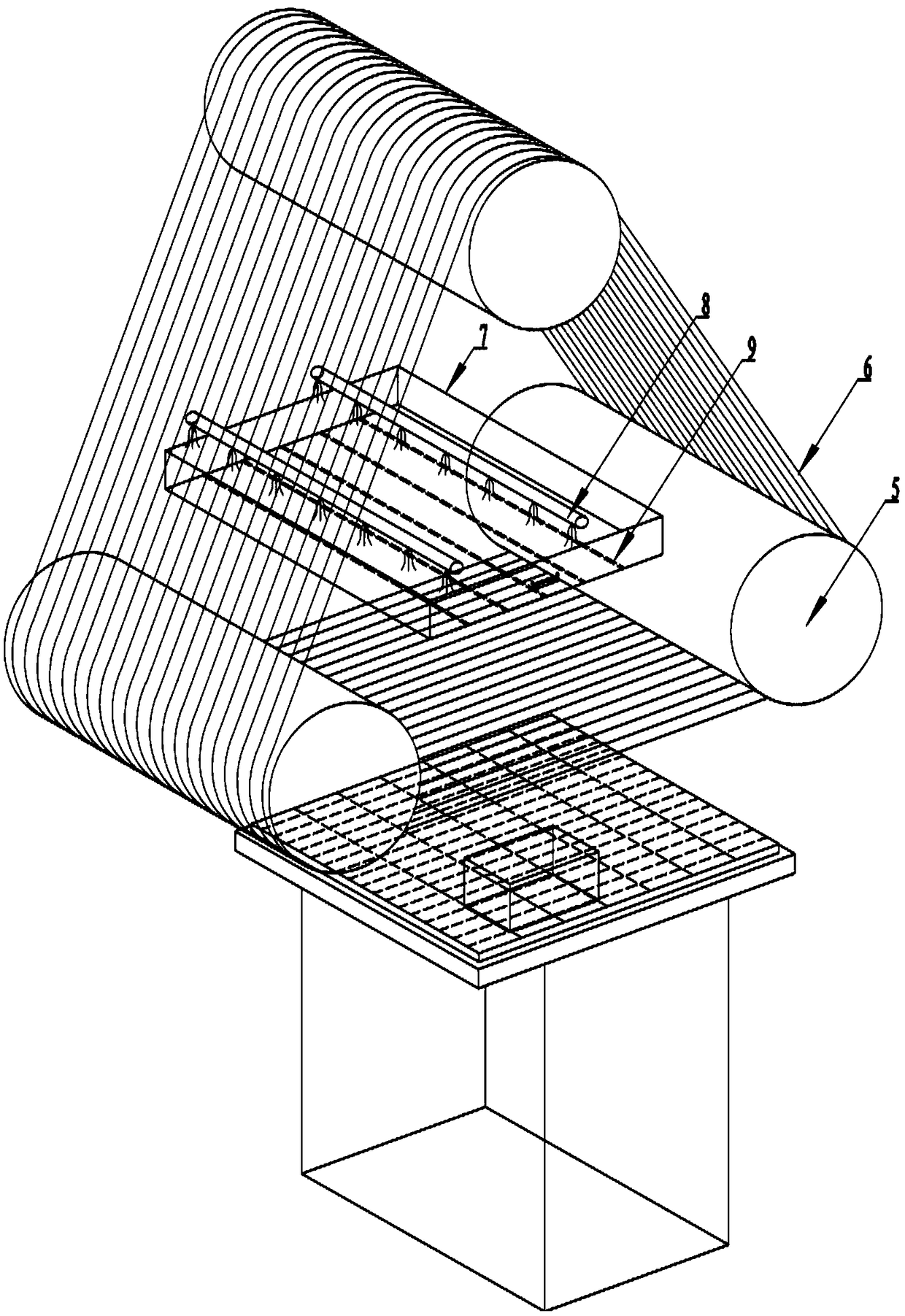

[0053] The multi-wire cutting machine consists of three sheaves on which several cutting wires arranged in parallel are wound, a working table located below the cutting lines, and a liquid leakage pipe located above the cutting lines.

[0054] Wherein, the surface of each sheave is coated with a polyurethane coating, and a plurality of V-shaped grooves with uniform groove spacing are opened on the polyurethane coating. It is also equipped with driving devices such as guide wheels, swing rods, take-up wheels, and pay-off wheels for the movement of the cutting line.

[0055] The worktable is driven by a screw rod and a servo device, and can move from bottom to top at a set speed.

[0056] The liquid suction pump provides power to make the mortar or coolant spray out from the leakage pipe, flow into the leakage box, and then evenly flow to the cutting line through the gap of the leakage box.

[0057] The units of dimensions described below are mm, the size of the multi-wire cutt...

Embodiment 2

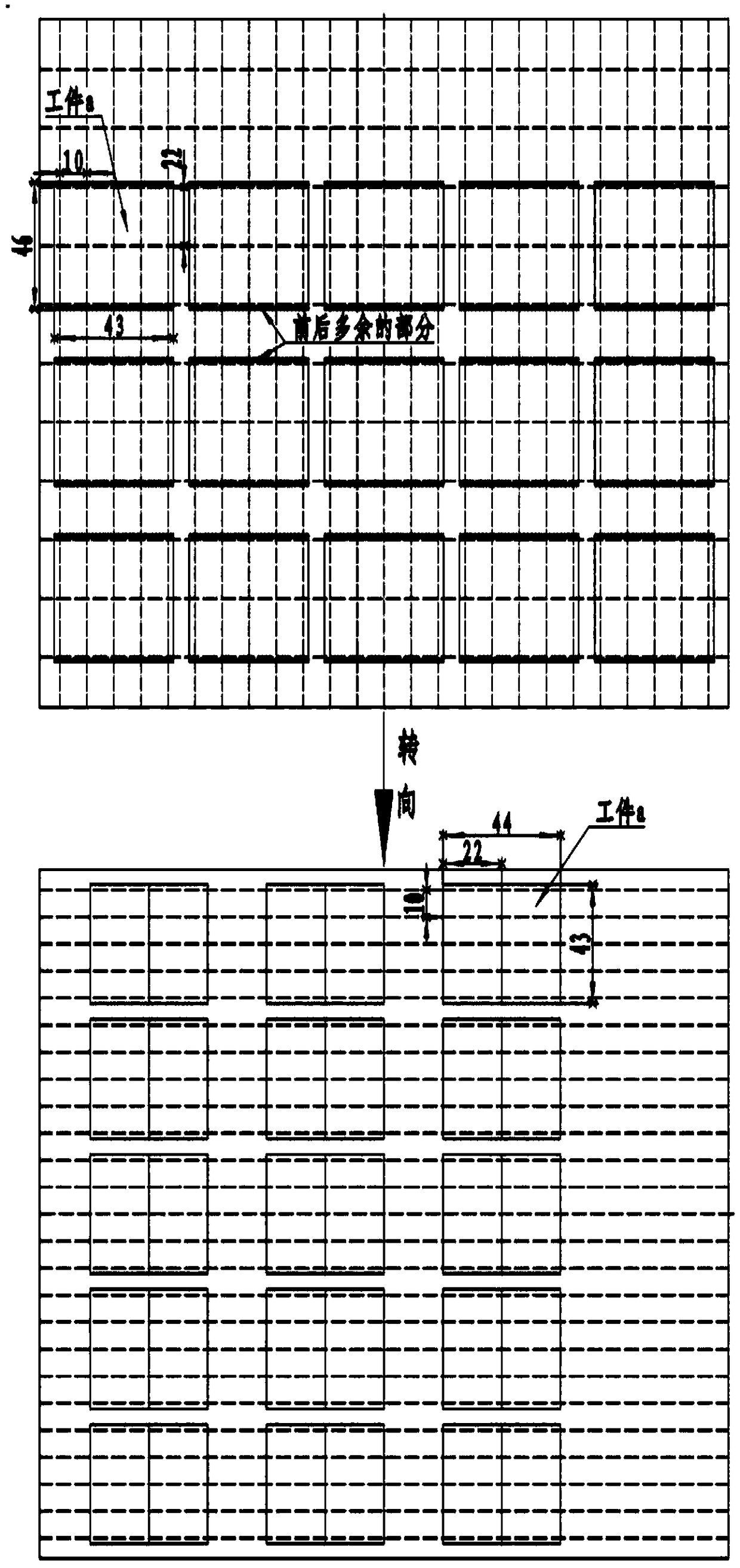

[0062] Embodiment 2 is basically the same as the multi-wire cutting method and multi-wire cutting machine of embodiment 1, and its difference is as Figure 4 As shown, the size of the two directions of the cut block is the same. The size of the block workpiece b is 46*46*38 as an example. After cutting, the corresponding size is 22*22*5. size.

[0063] In the above embodiment 2, only two multi-wire cutting machines are needed to complete the cutting in three directions.

[0064] The following table is the comparison of the processing time of each process of cutting 9 pieces of workpieces with a size of 46*46*38 into 252 pieces of 22*22*5 in Example 2. It can be seen that Example 2 can save about 24% of time:

[0065]

Embodiment 3

[0067] The multi-wire cutting method and the multi-wire cutting machine in embodiment 3 and embodiment 1 are basically the same, the difference is that the size of one direction of the square workpiece does not need to be cut, taking 46*43*15 as an example, the corresponding size after cutting For 22*10*15, only need to cut 22 and 10 direction size.

[0068] In the above embodiment 3, only two multi-wire cutting machines are needed to complete the cutting in two directions.

[0069] The following table is the comparison of the processing time of each process of cutting 15 pieces of workpieces with a size of 46*43*15 into 120 pieces of 22*10*15 in Example 3. It can be seen that Example 3 can save about 33% of time:

[0070]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com