Reflective NEA GaN nanowire array photoelectric negative electrode and manufacturing method therefor

A nanowire array and photocathode technology, applied in the fields of photoemission cathode, cold cathode manufacturing, electrode system manufacturing, etc., can solve the problems of low repeatability, expensive equipment, high emissivity of thin film materials, etc., to improve quantum efficiency, The loss of energy is small, and the effect of overcoming the conflicting relationship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0041] The method of adsorbing and arranging nano-scale Ni catalyst particles neatly on the surface of the substrate:

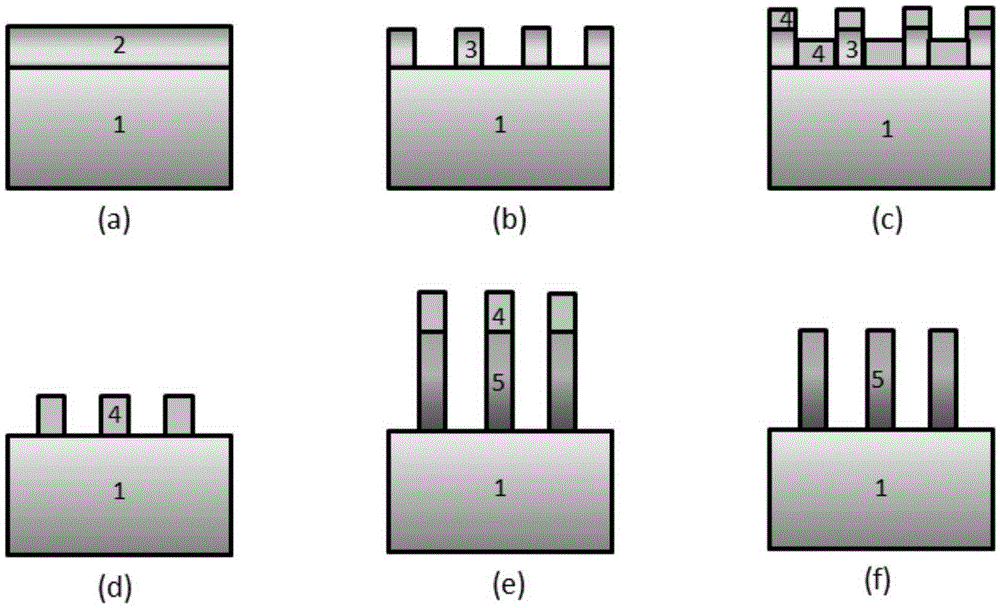

[0042] First, clean the Si or SiC substrate 1 with sulfuric acid and hydrogen peroxide at a volume ratio of 1:1, then use 5% hydrofluoric acid to etch and clean the Si or SiC substrate, and use an electron beam on the cleaned substrate surface The evaporation method evaporates a metal Al layer on the substrate layer to form an Al thin film 2, such as figure 2 As shown in (a), the thickness of the Al film 2 is 100-1000nm; the substrate evaporated with the Al film 2 is placed in a 0.5mol / L oxalic acid solution for electrochemical corrosion, and a porous aluminum oxide film is formed on the surface of the substrate. put the substrate with aluminum oxide film on the surface layer after electrochemical corrosion into 4% phosphoric acid by mass percentage and 2% chromic acid mixed solution for immersion, remove the aluminum oxide in contact with the substrate at t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com