Sand wind speed reducing plate, sand-preventing barrier, manufacturing method and application thereof

A speed brake and sand blowing technology, applied in climate change adaptation, soil protection, construction, etc., can solve the problems of non-degradable plastic sand-blocking and sand-fixing nets, large labor requirements for laying, high cost of stone grids, etc., and achieve good environmental stability Good performance and anti-aging performance, easy to recycle and reuse, and avoid the effects of wind and sand damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

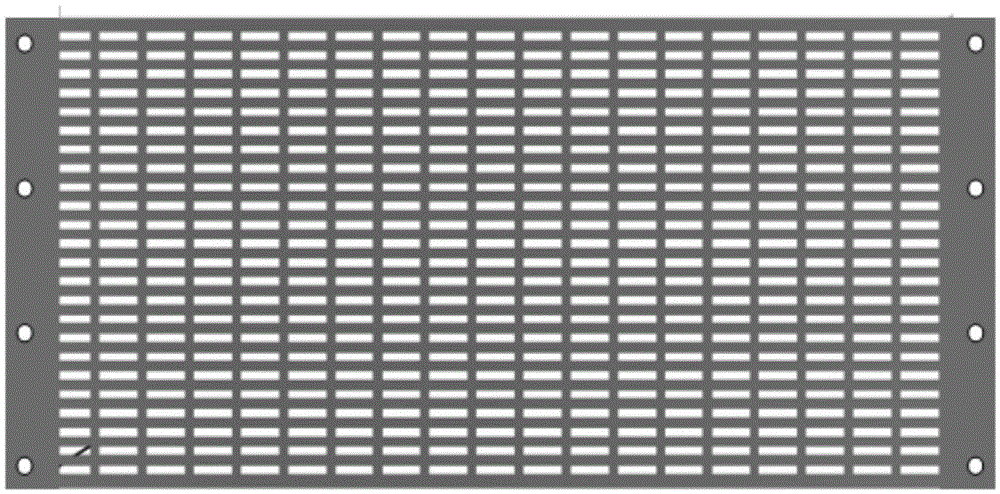

[0034] In the present invention, the wind and sand deceleration plate is a polymer plate made of high-density polyethylene (HDPE) as the main raw material, adding anti-ultraviolet additives, colorants (for example, color masterbatch) and other auxiliary materials, and there are polygonal shapes distributed on the plate. holes and round holes. The preparation method of the wind-sand speed brake of the present invention comprises: (1) batching, (2) dry mixing of raw materials, (3) extruding, (4) calendering, (5) punching, (6) drying, (7) ) detection.

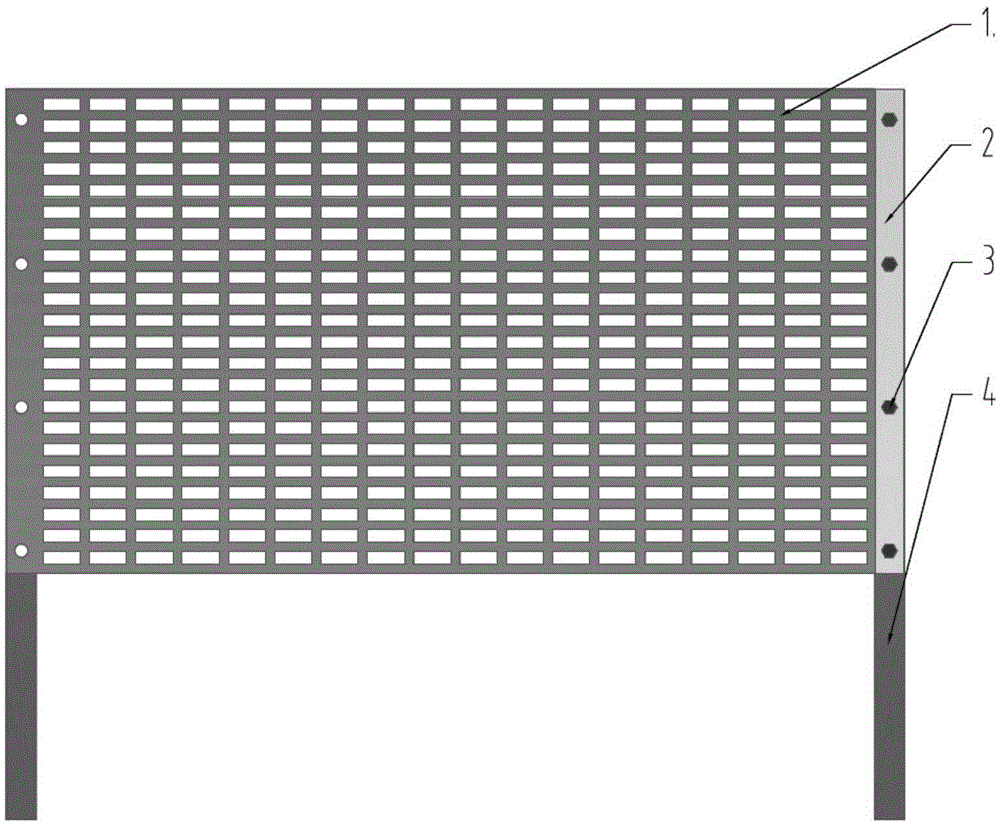

[0035] figure 2 As shown, the sand prevention barrier of the present invention is formed in the following manner: the wind-sand deceleration plate 1 is fixed between the column 4 and the pressure plate 2 with, for example, bolts 3 and pressing plate 2; the bottom of the column 4 is buried under the desert soil, preferably Ground, described wind-sand speed-brake and column and desert become vertical shape, and many wind-sand spe...

Embodiment 1

[0079] (1) Ingredients

[0080] Weigh 100kg of high-density polyethylene (HDPE), 6kg of anti-ultraviolet auxiliary agent, and 0.4kg of green color masterbatch. Among them, the silicon dioxide content in the anti-ultraviolet auxiliary agent is 1%; the particle size is 20.0nm, and the dispersion appearance grade is A3.

[0081] (2) dry mixing of raw materials

[0082] Put the weighed raw materials into the mixer for drying and stir evenly, the drying temperature is 85°C, and the drying and mixing time is 23 minutes.

[0083] (3) extrusion

[0084] Add the dried and mixed raw materials into the extruder to extrude a plate with a thickness of 2mm, a width of 2.1m, and a length of 2.0m. The working parameters of the extruder are: the extrusion rate is 120 kg / hour, and the extrusion temperature is 180°C.

[0085] (4) calendering

[0086] Pass the extruded sheet through a three-roller calender to smooth, calender and flatten it. The working parameters are: the temperature of the...

Embodiment 2

[0104] (1) Ingredients

[0105] Weigh 100kg of high-density polyethylene (HDPE), 10kg of anti-ultraviolet auxiliary agent, and 0.5kg of green color masterbatch, wherein the content of silicon dioxide in the anti-ultraviolet auxiliary agent is 1.2%; the particle size is 22.0nm, and the apparent dispersion level is A3.

[0106] (2) dry mixing of raw materials

[0107] Put the weighed raw materials into the mixer for drying and stir evenly, the drying temperature is 95°C, and the drying and mixing time is 25 minutes.

[0108] (3) extrusion

[0109] Add the dry and mixed raw materials into the extruder to extrude a plate with a thickness of 2.5mm, a width of 3.1m, and a length of 3.0m. The working parameters of the extruder are: extrusion rate 150 kg / h, extrusion temperature 200°C.

[0110] (4) calendering

[0111] Pass the extruded board through a three-roller calender to smooth it, calender and flatten it. The working parameters are: roller temperature 200°C, roller speed at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com