Special flow type silicone sealant for road

A silicone sealant, road technology, applied in the direction of adhesives, adhesive additives, non-polymer adhesive additives, etc. Weathering performance, excellent high and low temperature resistance, the effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

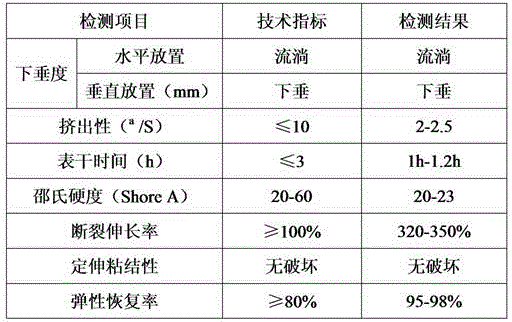

Image

Examples

Embodiment 1

[0022] A special silicone sealant for flowing roads, comprising the following raw materials in parts by weight: 54 parts of room temperature vulcanized methyl silicone rubber with a viscosity of 1200mPa·s, 125 parts of room temperature vulcanized methyl silicone rubber with a viscosity of 20000mPa·s, silicon micropowder 210 parts, 122 parts of nano-calcium carbonate, 1 part of di-n-butyltin dilaurate, 22 parts of methyl tributylketoxime silane, 5 parts of vinyl tributylketoxime silane, and 1 part of coupling agent. The coupling agent is a silane coupling agent.

[0023] The preparation method of the special silicone sealant for the flowing type road comprises the following steps:

[0024] (1) Add room temperature vulcanized methyl silicone rubber, silicon micropowder and nano-calcium carbonate of various viscosities into the vacuum kneader, heat up and stir, start vacuum dehydration at 100°C, and then heat the mixture at a temperature of 150°C, a vacuum degree of 0.07MPa, and ...

Embodiment 2

[0027] A special silicone sealant for flowing roads, comprising the following raw materials in parts by weight: 55 parts of room temperature vulcanized methyl silicone rubber with a viscosity of 1500 mPa s, 115 parts of room temperature vulcanized methyl silicone rubber with a viscosity of 18000 mPa s, silicon micropowder 215 parts, 125 parts of nano-calcium carbonate, 0.5 part of di-n-butyltin dilaurate, 25 parts of methyl tributylketoxime silane, 6 parts of vinyl tributylketoxime silane, and 1.5 parts of coupling agent. The coupling agent is a silane coupling agent.

[0028] The preparation method of the special silicone sealant for the flowing type road comprises the following steps:

[0029] (1) Add room temperature vulcanized methyl silicone rubber, silicon micropowder and nano-calcium carbonate of various viscosities into the vacuum kneader, heat up and stir, start vacuum dehydration at 80°C, and then vacuumize at 100°C, vacuum degree 0.08MPa, speed Stir for 2 hours und...

Embodiment 3

[0032] A special silicone sealant for flowing roads, comprising the following raw materials in parts by weight: 58 parts of room temperature vulcanized methyl silicone rubber with a viscosity of 1600 mPa s, 120 parts of room temperature vulcanized methyl silicone rubber with a viscosity of 20000 mPa s, silicon micropowder 220 parts, 130 parts of nano-calcium carbonate, 0.1 part of di-n-butyltin dilaurate, 30 parts of methyl tributylketoximosilane, 8 parts of vinyl tributylketoximosilane, and 1.2 parts of coupling agent. The coupling agent is a silane coupling agent.

[0033] The preparation method of the special silicone sealant for the flowing type road comprises the following steps:

[0034] (1) Add room temperature vulcanized methyl silicone rubber, silicon micropowder and nano-calcium carbonate of various viscosities into the vacuum kneader, heat up and stir, start vacuum dehydration at 100°C, and then vacuumize and dehydrate at 120°C, vacuum degree 0.09MPa, speed Stir fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com