High-heat-conductive composition, preparation method and heat-conductive gasket thereof

A composition and high thermal conductivity technology, applied in chemical instruments and methods, heat exchange materials, etc., can solve the problems of high interface thermal resistance and poor dispersion, achieve high surface activity, good thermal conductivity, and reduce interface thermal resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

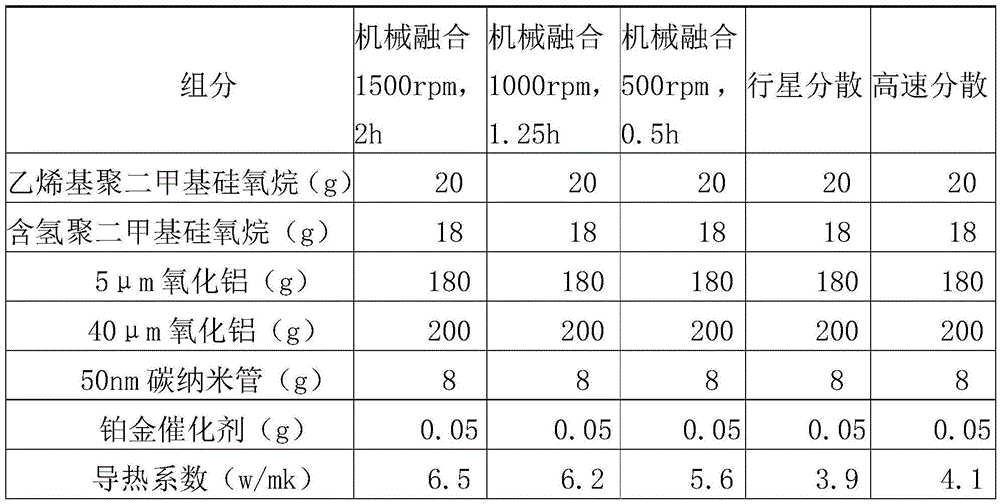

Embodiment 1

[0022] High thermal conductivity composition, including the following components in mass percentage: vinyl polydimethylsiloxane 4.7%, hydrogen-containing polydimethylsiloxane 4.3%, 40 μm alumina powder 47%, 5 μm alumina powder 42% , 50nm carbon nanotubes 1.99%, platinum catalyst 0.01%.

[0023] The preparation method of high thermal conductivity composition comprises the following steps:

[0024] Step 1: The heat-conducting powder is added to the fusion machine for fusion treatment. The speed of the fusion machine is 500rpm, the fusion time is 0.5h, and the process is water-cooled to obtain a composite heat-conducting filler;

[0025] Step 2: Add the above composite thermally conductive filler, vinyl polydimethylsiloxane and hydrogen-containing polydimethylsiloxane into the planetary disperser, stir and mix evenly, the speed of the planetary disperser is 5rpm-30rpm, and the stirring time is 10min ~30min, and then vacuumize to obtain the rubber.

[0026] The rubber compound p...

Embodiment 2

[0028] As for the high thermal conductivity composition described in Example 1, this example has the following differences: it includes the following components in mass percentage: vinyl polydimethylsiloxane 4.7%, hydrogen-containing polydimethylsiloxane 4.3%, 40μm zinc oxide powder 47%, 5μm alumina powder 42%, 50nm carbon nanotube 1.99%, platinum catalyst 0.01%.

[0029] The preparation method of high thermal conductivity composition comprises the following steps:

[0030] Step 1: The heat-conducting powder is added to the fusion machine for fusion treatment. The speed of the fusion machine is 1000rpm, the fusion time is 1.25h, and the process is water-cooled to obtain a composite heat-conducting filler;

[0031] Step 2: Add the above composite thermally conductive filler, vinyl polydimethylsiloxane and hydrogen-containing polydimethylsiloxane into the planetary disperser, stir and mix evenly, the speed of the planetary disperser is 5rpm-30rpm, and the stirring time is 10min ...

Embodiment 3

[0034] As described in the first and second embodiments, this embodiment has the following differences: it includes the following components in mass percentage: vinyl polydimethylsiloxane 4.7%, hydrogen-containing polydimethylsiloxane Oxane 4.3%, 40 μm alumina and zinc oxide powder 47%, 5 μm alumina powder 42%, 50nm carbon nanotube 1.99%, platinum catalyst 0.01%.

[0035] The preparation method of high thermal conductivity composition comprises the following steps:

[0036] Step 1: The heat-conducting powder is added to the fusion machine for fusion treatment. The speed of the fusion machine is 1500rpm, the fusion time is 2h, and the process is water-cooled to obtain a composite heat-conducting filler;

[0037] Step 2: Add the above composite thermally conductive filler, vinyl polydimethylsiloxane and hydrogen-containing polydimethylsiloxane into the planetary disperser, stir and mix evenly, the speed of the planetary disperser is 5rpm-30rpm, and the stirring time is 10min ~3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com