Winding pipe for hollow composite insulator and preparation method of winding pipe for hollow composite insulator

A technology of composite insulators and wound pipes, which is applied in applications, household appliances, tubular objects, etc., can solve the problem that the airtightness, anti-aging performance and mechanical strength of the products cannot meet the requirements of use, and the amount of glue hanging on monofilaments is not enough. Good control, affecting yield and mechanical strength and other issues, to achieve good economic benefits, shorten the production cycle, and good electrical breakdown resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The winding tube for hollow composite insulators in this embodiment is formed by winding and curing glass fibers impregnated with epoxy resin glue. The epoxy resin glue is composed of the following raw materials in parts by weight: 80 parts of epoxy resin, methyl tetra 65 parts of hydrophthalic anhydride, 10 parts of propylene oxide butyl ether, 3 parts of 2,4,6-tris(dimethylaminomethyl)phenol, 0.5 part of BYKA530 defoamer; the glue content of the winding tube is 25% (mass percentage). The glass fiber is non-alkali glass fiber non-twisted yarn.

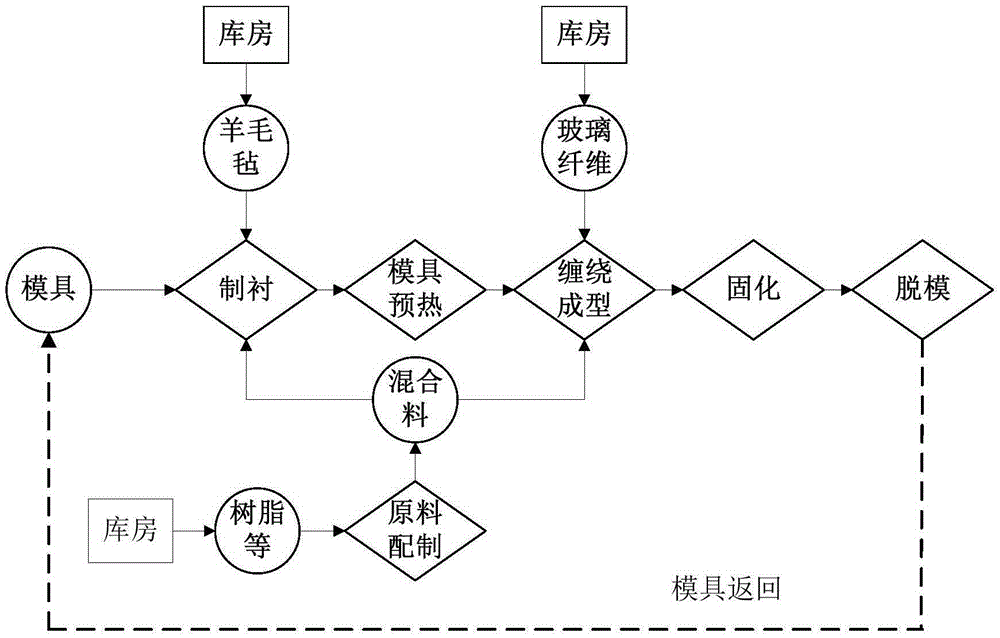

[0044] The preparation method of the wound pipe for the hollow composite insulator of this embodiment, the process flow is as follows figure 1 shown, including the following steps:

[0045] 1) Glue compounding: Take E51 type epoxy resin, methyl tetrahydrophthalic anhydride, propylene oxide butyl ether, 2,4,6-tris(dimethylaminomethyl)phenol and BYKA530 defoamer and mix evenly Prepare epoxy resin glue, heat the epoxy resin glu...

Embodiment 2

[0054] The winding pipe for hollow composite insulators in this embodiment is formed by winding and curing glass fibers impregnated with epoxy resin glue, and the epoxy resin glue is composed of the following raw materials in parts by weight: 100 parts of epoxy resin, methyl tetra 80 parts of hydrophthalic anhydride, 5 parts of propylene oxide butyl ether, 2 parts of 2,4,6-tris(dimethylaminomethyl)phenol, 0.3 parts of BYKA530 defoamer: the glue content of the winding tube is 27% (mass percentage). The glass fiber is an alkali-free glass fiber roving.

[0055] The preparation method of the wound pipe for the hollow composite insulator of this embodiment, the process flow chart is the same as that of Embodiment 1, including the following steps:

[0056] 1) Glue compounding: Take E51 type epoxy resin, methyl tetrahydrophthalic anhydride, propylene oxide butyl ether, 2,4,6-tris(dimethylaminomethyl)phenol and BYKA530 defoamer and mix evenly Prepare epoxy resin glue, heat the epox...

Embodiment 3

[0065] The winding tube for hollow composite insulators in this embodiment is formed by winding and curing glass fibers impregnated with epoxy resin glue. The epoxy resin glue is composed of the following raw materials in parts by weight: 120 parts of epoxy resin, methyl tetra 50 parts of hydrophthalic anhydride, 8 parts of propylene oxide butyl ether, 5 parts of 2,4,6-tris(dimethylaminomethyl)phenol, 0.1 part of BYKA530 defoamer; the glue content of the winding tube is 30% (mass percentage). The glass fiber is an alkali-free glass fiber roving.

[0066] The preparation method of the wound pipe for the hollow composite insulator of this embodiment, the process flow is as follows figure 1 shown, including the following steps:

[0067] 1) Glue compounding: Take E51 type epoxy resin, methyl tetrahydrophthalic anhydride, propylene oxide butyl ether, 2,4,6-tris(dimethylaminomethyl)phenol and BYKA530 defoamer and mix evenly Prepare epoxy resin glue, heat the epoxy resin glue at 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Winding angle | aaaaa | aaaaa |

| Winding angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com