Method for preparing high-filling composite masterbatch through semi-open type superheated steam spray-drying method

A technology of spray drying and superheated steam, which is applied in the field of preparing high-filling composite masterbatch, can solve the problems of restricting the development of spray drying, rubber thermal oxygen aging, combustion, etc. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

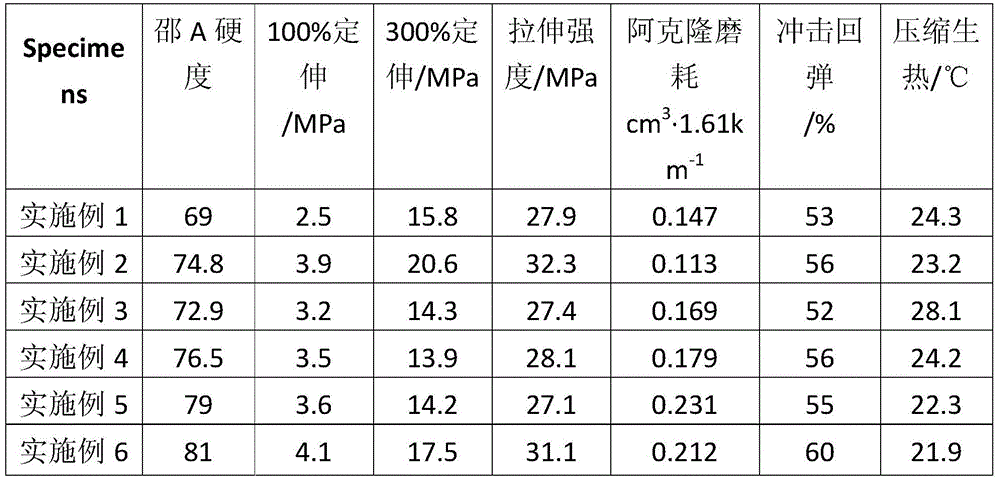

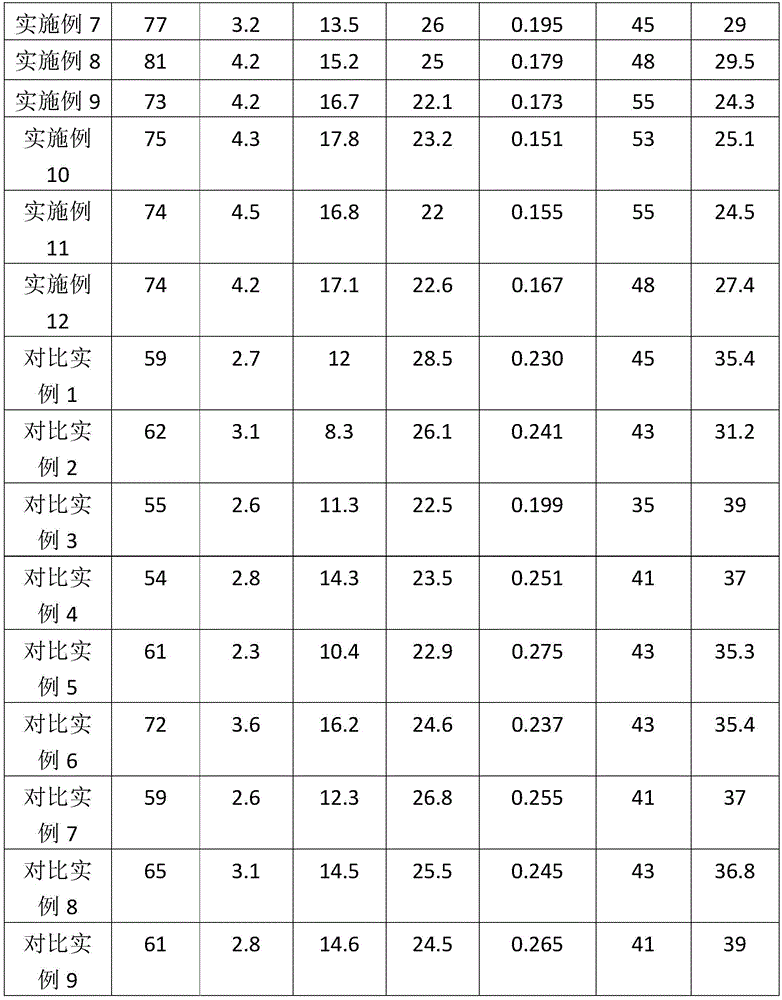

Embodiment 1

[0036]Add 30 g of commercially available carbon black N234 powder into 970 g of water, stir evenly, then add 15 g of ethanol, stir and grind for 15 minutes to obtain a carbon black suspension. Under stirring, 333.3g of natural emulsion with a solid content of 30% was mixed to obtain a mixed solution with a particle size of 5 μm colloidal particles, and the evenly stirred mixed solution was subjected to semi-open superheated steam spray drying treatment, and the atomized droplets were controlled at 30 μm , the spray drying inlet temperature is 150°C, and the outlet temperature is 80°C to obtain powdered nanocomposite masterbatch, and ethanol is condensed and recovered during the drying process. Take the above masterbatch 130phr, ZnO5phr, stearic acid 2phr, anti-aging agent 1010NA1phr, accelerator CZ1.2phr, sulfur 2phr, mix the rubber, measure the vulcanization curve and rubber processing performance after parking for 8 hours, vulcanize at 143 ° C, and measure the mechanical prop...

Embodiment 2

[0038] Add 60 g of commercially available carbon black N330 powder into 140 g of water, stir evenly, then add 60 g of ethanol, stir and grind for 15 min to obtain a carbon black suspension. Under stirring, mix 333.3g of natural rubber latex with a solid content of 30% to obtain a mixed solution with a particle size of 20 μm, and carry out a semi-open superheated steam spray drying treatment on the mixed solution evenly stirred, and control the atomized droplets at 100 μm , the spray drying inlet temperature is 350°C, and the outlet temperature is 120°C to obtain powdered nanocomposite masterbatch, and ethanol is condensed and recovered during the drying process. Get above-mentioned masterbatch 160phr, all the other steps are with embodiment 1.

Embodiment 3

[0040] Add 50 g of commercially available carbon black N110 powder into 450 g of water, stir evenly, then add 30 g of ethanol, stir and grind for 15 min to obtain a carbon black suspension. Under stirring, mix 250g of styrene-butadiene latex with a solid content of 40% to obtain a mixed solution with a particle size of 10 μm colloidal particles, and carry out a semi-open superheated steam spray drying process on the evenly stirred mixed solution, and control the atomized droplets at 50 μm , the spray drying inlet temperature is 250°C, and the outlet temperature is 100°C to obtain powdered nanocomposite masterbatch, and ethanol is condensed and recovered during the drying process. Get above-mentioned masterbatch 150phr, all the other steps are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com