Lutetium-aluminum garnet scintillation ceramic in non-stoichiometric ratio and preparation method for ceramic

A non-stoichiometric ratio, lutetium aluminum garnet technology, applied in the field of preparation of transparent scintillation ceramics, can solve problems such as performance defects, and achieve the effect of huge application potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The method for preparing lutetium aluminum garnet scintillation ceramics can be prepared by solid phase reaction method, according to the stoichiometric ratio [Lu (1-x) RE x ] 3 Al 5 o 12 Carry out ingredient weighing Al 2 o 3 and RE high-purity oxides, while Lu 2 o 3 The powder needs to weigh (3 / 2)(1-x)(1+y)mol. The oxide powder raw materials are uniformly mixed by ball milling, absolute ethanol is used as the ball milling medium, the ball milling speed is 60-150rmp / min, and the ball milling time is 5-20h.

[0037] The method for preparing lutetium-aluminum-garnet scintillation ceramics can be prepared by liquid-phase method, directly using liquid-phase synthesis such as precipitation method or sol-gel combustion synthesis to obtain a component of [Lu (1-x)(1+y) RE x ] 3 Al 5 o 12 the initial powder.

[0038] The method for preparing lutetium aluminum garnet scintillation ceramics is prepared into a green body by dry pressing, cold isostatic pressing, coll...

Embodiment 1

[0058] Embodiment 1: x=0.005, y=0.03, 0.5at% Ce: (Lu 0.995×1.03 ) 3 Al 5 o 12

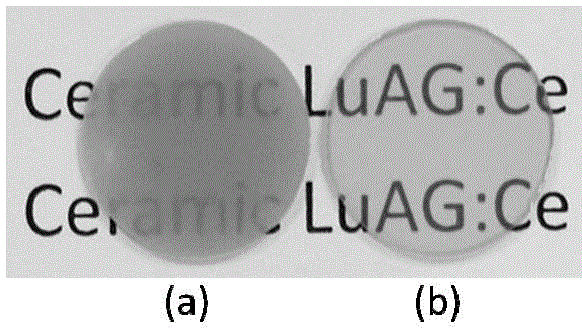

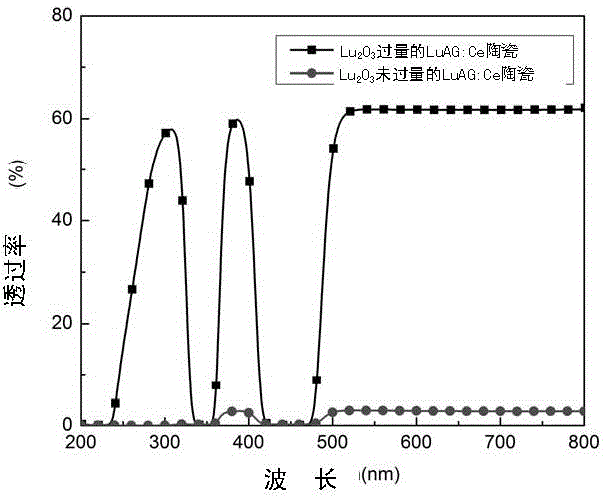

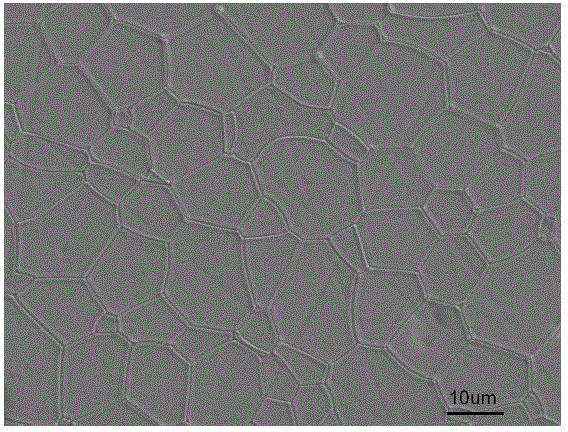

[0059] Using commercially available high-purity Lu 2 o 3 (99.99%), Al 2 o 3 (99.99%) and CeO 2 (99.99%) powder as raw material, according to (Lu 0.995×1.03 Ce 0.005 ) 3 al 5 o 12 The chemical formula is weighed, using absolute ethanol as the ball milling medium, the ratio of the sum of the mass of the above-mentioned oxides to the amount of ethanol added is 60g:25ml, and ball milling on a high-energy ball mill for 10-20h at a ball milling speed of 60-120rmp / min. After the ball-milled slurry is dried and sieved, the ceramic green body is obtained by dry pressing and cold isostatic pressing in sequence. The green body is sintered in a vacuum furnace with a sintering temperature range of 1700-1850°C and a holding time of 5-50 Hour. The ceramic samples obtained by vacuum sintering were annealed in an air atmosphere at 1200°C-1600°C for 5-50h, then mechanically thinned and polished to obtain...

Embodiment 2

[0067] Embodiment 2: x=0.003, y=0.02, 0.3at%Ce: (Lu 0.997×1.02 ) 3 al 5 o 12

[0068] Using commercially available high-purity Lu 2 o 3 (99.99%), Al 2 o 3 (99.99%) and CeO 2 (99.99%) powder as raw material, according to (Lu 0.997×1.02 Ce 0.003 ) 3 al 5 o 12 The chemical formula is weighed, using absolute ethanol as the ball milling medium, the ratio of the sum of the mass of the above-mentioned oxides to the amount of ethanol added is 60g:25ml, and ball milling on a high-energy ball mill for 10-20h at a ball milling speed of 60-120rmp / min. After the ball-milled slurry is dried and sieved, the ceramic green body is obtained by dry pressing and cold isostatic pressing in sequence. The green body is sintered in a vacuum furnace with a sintering temperature range of 1700-1900°C and a holding time of 5-50 Hour. The ceramic samples obtained by vacuum sintering were annealed in the mixture of oxygen and air for 5-50 hours, the annealing temperature range was 1200°C-1600...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com