Hot gold foil

A technology of hot stamping paper and base film, applied in the field of hot stamping paper, can solve the problems of limited application scope of hot stamping paper, unrealistic hot stamping of metal foil, insufficient adhesion of metal foil, etc., and achieves exquisite patterns, good hot stamping effect, and hot stamping high quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

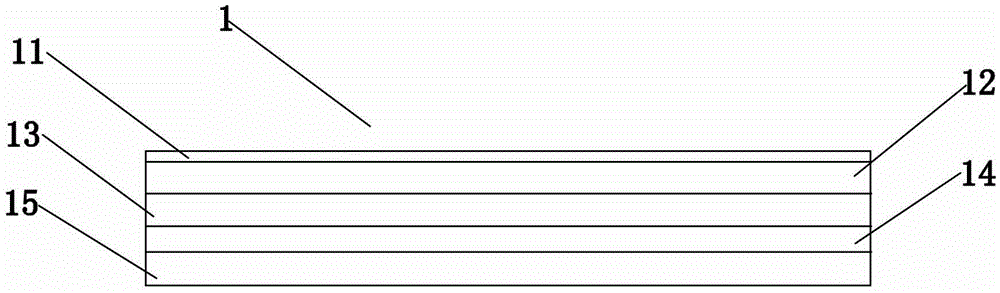

[0025] Embodiment one, see figure 1 Shown, a kind of bronzing paper 1 comprises base film layer 11, the release layer 12 on the base film layer 11, the colored layer 13 on the release layer 12 and the aluminized layer 14 on the colored layer 13, and described aluminized The bottom of the layer 14 is provided with an ink layer 15, and the mass percentage of each component of the ink layer 15 is composed of: 25-35% epoxy resin, 35-45% polyester resin, 20-30% auxiliary agent, 2- 8% defoamer and leveling agent.

[0026] As a more specific technical solution of the present invention.

[0027] Preferably, the mass percentage of the epoxy resin is 30%.

[0028] Preferably, the mass percentage of the polyester resin is 40%.

[0029] Preferably, the mass percentage of the auxiliary agent is 25%.

[0030] Preferably, the mass percent of the defoamer and leveling agent is 5%.

[0031] Preferably, the auxiliary agent is isophorone.

[0032] Preferably, the base film layer 11 is a PE...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com