Wet flue gas desulfurization tower with deep dehumidification function and dehumidification process

A wet flue gas desulfurization and desulfurization tower technology, applied in the field of wet flue gas desulfurization, can solve the problems of reducing chimney anti-corrosion investment, complex system, high cost, etc. The effect of heat increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

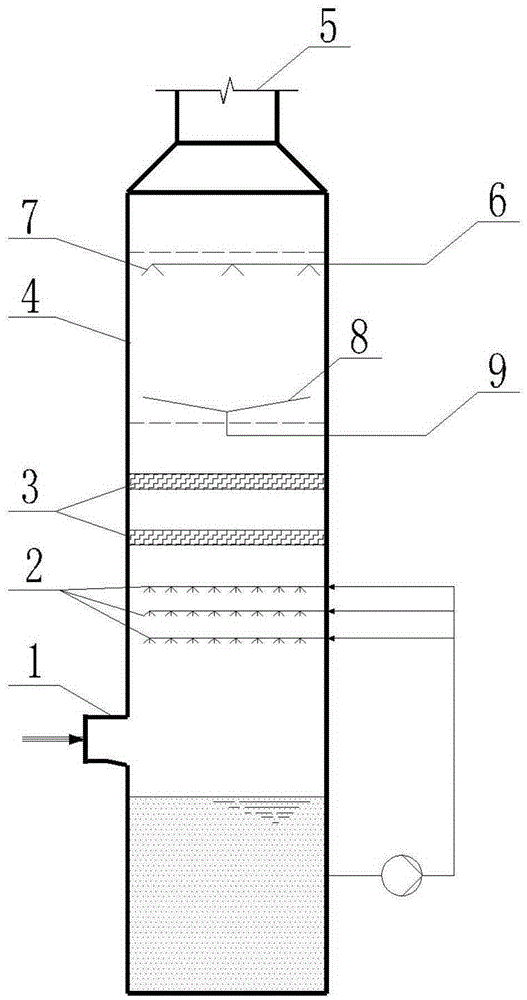

[0031] A wet flue gas desulfurization tower with deep dehumidification function. The inlet of the desulfurization tower is connected to the inlet flue 1, and the top is the flue gas outlet 5. The desulfurization tower is equipped with a desulfurization spray layer 2 and a demister in sequence from the middle to the upper part. 3 and a dehumidifier 4, the dehumidifier 4 includes a dehumidification nozzle 7 and a liquid contact device 8 located below the dehumidification nozzle 7, the top of the dehumidifier is provided with a dehumidification working fluid inlet 6, the dehumidification working fluid inlet 6 is connected to the dehumidification nozzle 7, and the liquid contact device The middle part of 8 connects dilute working medium outlet 9.

[0032] The coal-fired flue gas enters the desulfurization tower through the inlet flue 1, and after being washed and desulfurized by the desulfurization spray layer 2, and most of the liquid droplets are removed by the demister 3, the sa...

Embodiment 2

[0037] The difference between this embodiment and embodiment 1 is:

[0038] Fillers are arranged below the dehumidification nozzle 7 to increase the mass transfer area, reduce the equipment volume and improve the dehumidification efficiency.

Embodiment 3

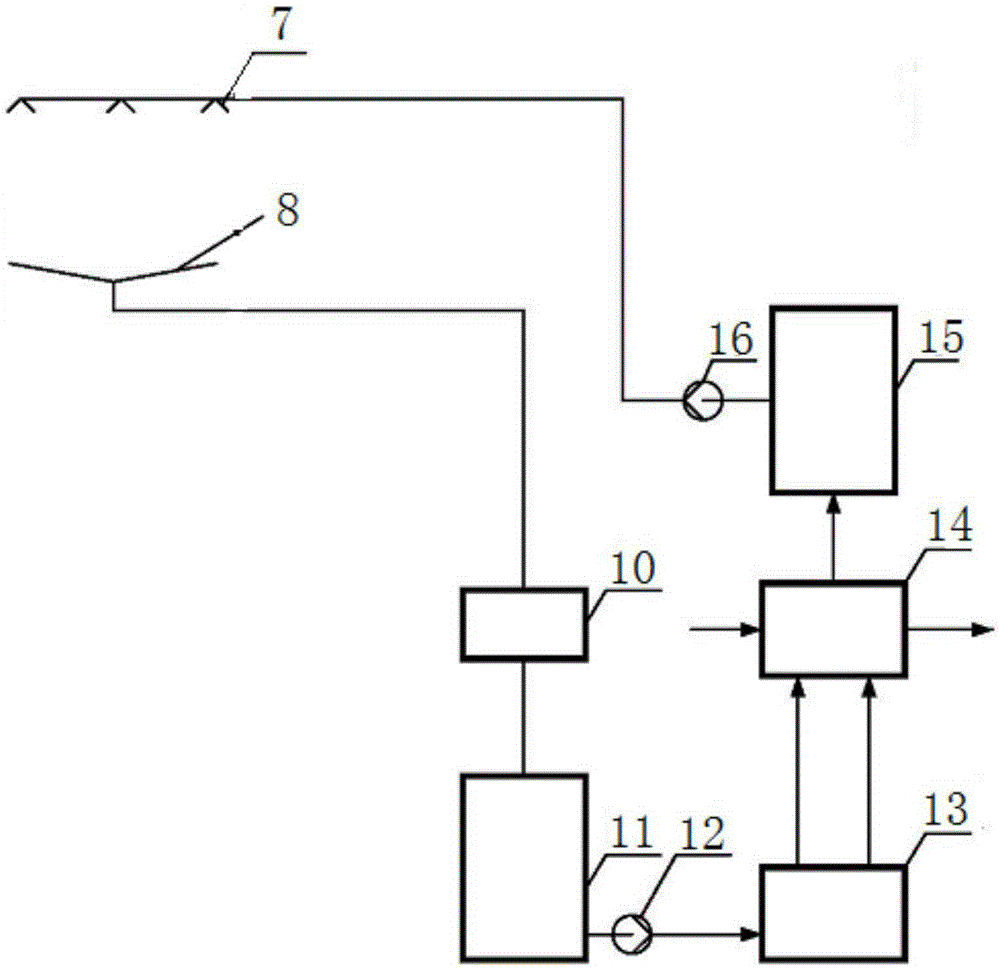

[0040] Such as figure 2 As shown, the liquid contact device 8 is connected to the working medium pool 15, and a purifier 10, a dilute working medium pool 11 and a water-liquid separator 13 are arranged successively between the liquid contact device 8 and the working medium pool, and the water-liquid separator 13 The vapor pressure of the dilute working fluid in the (flash evaporator) is higher than the water vapor partial pressure of the air in the water-liquid separator 13; Input to the dehumidifier 4, spray and absorb water vapor through the dehumidification nozzle 7 to form a dilute working fluid, then the dilute working fluid flows into the dilute working fluid pool 11 after being purified by the purifier, and is input to the water-liquid separator 11 through the dilute working fluid pump 12 Realize the separation of dehumidification working fluid and water, and the separated dehumidification working fluid is sent to the working fluid pool after cooling for recycling agai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com