Gas Absorption Falling Film Reactor

A falling film reactor and gas absorption technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of high axial velocity of gas, uneven gas distribution, uneven flow rate, etc., to eliminate fluctuations stability, ensuring stability and uniformity, and avoiding the effects of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

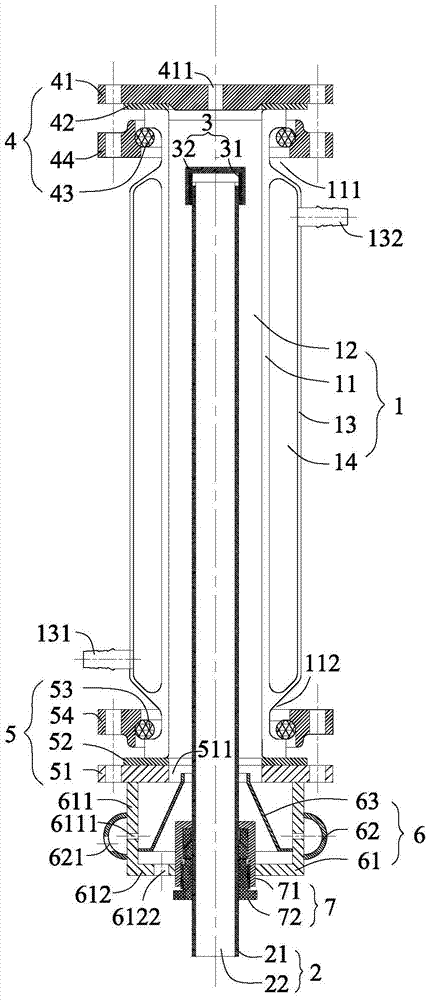

[0068] The gas absorption falling film reactor of the present invention will be described in detail below with reference to the accompanying drawings.

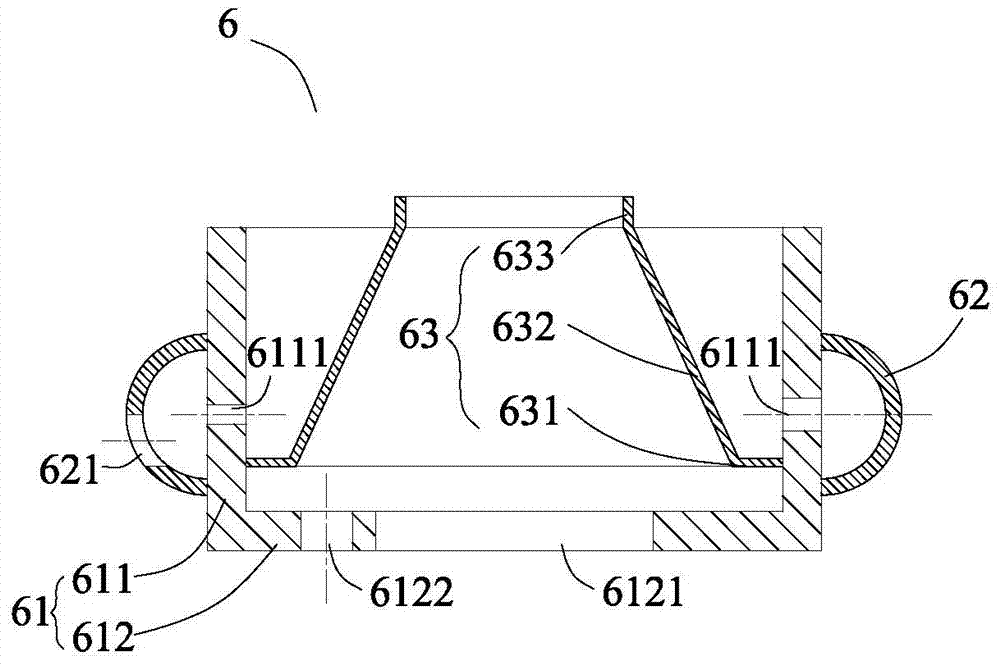

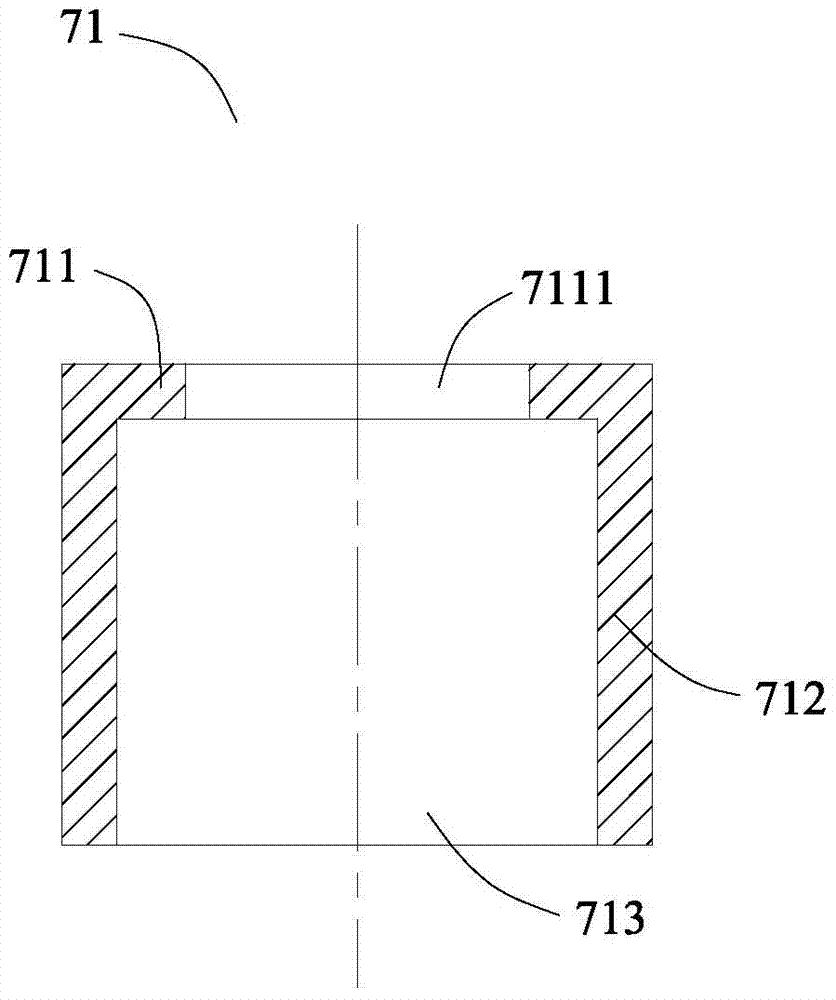

[0069] refer to Figure 1 to Figure 3 , The gas absorption falling film reactor according to the present invention includes a jacket 1 , a wetted wall column 2 , a liquid distribution mechanism 3 , an upper fixing mechanism 4 , a lower fixing mechanism 5 , a gas distribution mechanism 6 and a sealing mechanism 7 .

[0070] The jacket 1 has: an inner wall 11, which forms an accommodating cavity 12; and an outer wall 13, which surrounds the middle of the inner wall 11 and forms a first cavity 14 with the inner wall 11, and is provided with a heat transfer medium inlet 131 communicating with the first cavity 14 and The heat conduction medium outlet 132 , the heat conduction medium inlet 131 , the first cavity 14 and the heat conduction medium outlet 132 form a passage for the heat conduction medium (not shown), and the heat condu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com