Battery with membrane-coated electrodes

A coating and electrode technology, applied in the direction of electrode carrier/collector, battery electrode, secondary battery, etc., can solve the problems of limited charge and discharge life, complicated manufacturing process, poor ion conductivity and mechanical strength, etc., and achieve capacity and The effect of improving the working platform, increasing ion conductivity, and increasing safety and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

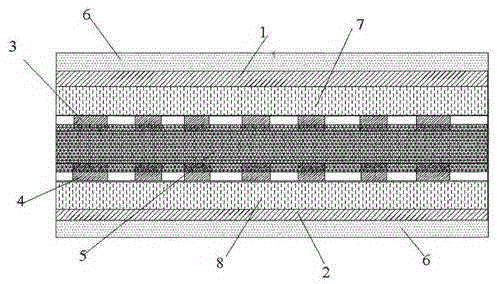

[0032] Such as figure 1 As shown, a polymer battery includes a positive electrode sheet 1 and a negative electrode sheet 2 arranged inside the battery casing 6, a separator 5 is arranged between the positive electrode sheet 1 and the negative electrode sheet 2; A positive electrode coating 7 and a positive electrode catalytic network 3 are provided. The positive electrode coating 7 covers the surface of the positive electrode sheet 1, and the positive electrode catalytic network 3 covers the surface of the separator 5; The net 4 and the negative electrode coating 8, the negative electrode catalytic net 4 is covered on the surface of the separator 5, the negative electrode coating 8 is covered on the surface of the negative electrode sheet 2, the positive electrode coating 7 is connected with the positive electrode catalytic net 3, the negative electrode coating 8 is connected to the negative electrode The catalytic nets 4 are connected.

[0033] The positive electrode sheet 1...

Embodiment 2

[0039] Such as figure 2 As shown, the nano-Rh-graphene composite electrode was prepared by the following steps,

[0040] Step 1: Weigh a portion of graphite powder, add an appropriate amount of concentrated sulfuric acid as a solvent in an ice bath, stir, and control the reaction temperature below 20°C, according to the mass ratio of graphite powder: sodium nitrate: potassium permanganate 1 :0.5:3 Slowly add sodium nitrate and potassium permanganate to the solution, stir for 10 minutes; raise the temperature to 35°C, stir for 3 hours, add deionized water to the solution according to the volume ratio of concentrated sulfuric acid: deionized water 1:0.2 , heat up to 98°C, stir for 30 minutes, then add deionized water according to the volume ratio of concentrated sulfuric acid: deionized water 1:0.5, stop the reaction, add 5% hydrogen peroxide to the solution according to the molar ratio of graphite powder: hydrogen peroxide 1:0.2, Heat centrifugation, wash with appropriate amo...

Embodiment 3

[0044] Such as image 3 As shown, the nano-Co 2 SnO 4 The polysulfonate naphthalene electrode is prepared by the following steps,

[0045] Step 1: Weigh a portion of SnCl 4 , take an appropriate amount of deionized water as a solvent, stir to dissolve, and add CoCl to the solution according to the tin chloride:cobalt chloride molar ratio of 1:2 2 According to tin chloride: sodium hydroxide molar ratio 1:10, add NaOH aqueous solution to the solution, stir at room temperature for 10 minutes, put the solution in the reaction kettle, feed nitrogen: oxygen 15:1, feed the mixed gas of nitrogen and oxygen , sealed, reacted at 240 ° C for 30 h, cooled naturally to room temperature, washed with deionized water and absolute ethanol, and lyophilized under a vacuum of 0.98 to obtain Co 2 SnO 4 powder;

[0046] Step 2: Weigh a portion of Co 2 SnO 4 Powder, according to the molar ratio of cobalt stannate:hydrochloric acid 1:15, add 2mol / L hydrochloric acid solution as a solvent, sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com