A synthetic method of cumenyl polyoxyethylene ether

A technology of cumyl polyoxyethylene ether and synthesis method, which is applied in the field of organic compound synthesis, and achieves the effects of stable quality, high double bond retention rate and narrow molecular weight distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

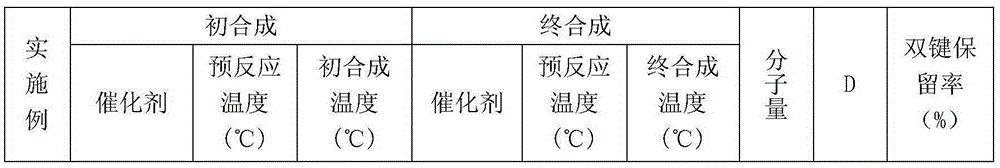

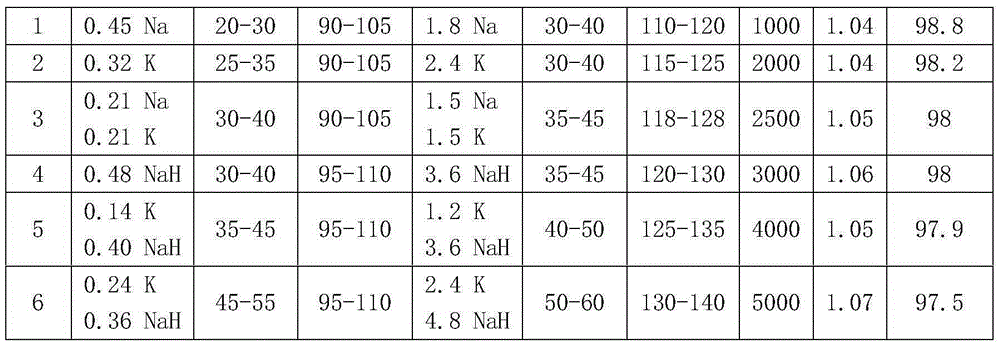

Examples

Embodiment 1

[0027] A kind of synthetic method of cumenyl polyoxyethylene ether of the present embodiment, comprises the steps:

[0028] 1) Add 42.0 parts of isopropenyl cumenol to the reaction kettle, add 0.45 parts of catalyst metal sodium within 30 minutes, control the reaction temperature to 20-30 ° C, and the reaction time is 0.5 hours; after the reaction, put the product into 798.0 Parts of isopropenyl cumenol, nitrogen replacement, heating up to 90°C, feeding 960 parts of ethylene oxide, controlling the reaction temperature to 90-105°C, and the reaction time is 4.0 hours; after the reaction, cool down to 70°C and discharge to obtain A cumenyl polyoxyethylene ether oligomer with a molecular weight of 300.

[0029] 2) Add 90 parts of the cumenyl polyoxyethylene ether oligomer with a molecular weight of 300 obtained in the step 1) into the reactor, add 1.8 parts of catalyst sodium metal within 30 minutes, and control the reaction temperature to 30-40°C , the reaction time was 0.5 hour...

Embodiment 2

[0032] A kind of synthetic method of cumenyl polyoxyethylene ether of the present embodiment, comprises the steps:

[0033] 1) Add 36.1 parts of isopropenyl cumenol in the reactor, add 0.32 parts of catalyst metal potassium within 50 minutes (begin to add catalyst within 50 minutes and complete within 50 minutes after adding the catalyst), and control the reaction temperature to 25-35°C, the reaction time is 0.5 hours; after the reaction, put the product into 383.9 parts of isopropenyl cumenol, replace it with nitrogen, raise the temperature to 90°C, feed 630 parts of ethylene oxide, and control the reaction temperature to 90 -105°C, the reaction time was 5.0 hours; after the reaction, the temperature was lowered to 70°C and discharged to obtain a cumenyl polyoxyethylene ether oligomer with a molecular weight of 350.

[0034] 2) Add 84 parts of the cumenyl polyoxyethylene ether oligomer with a molecular weight of 350 obtained in the step 1) to the reactor, add 2.4 parts of cat...

Embodiment 3

[0037] A kind of synthetic method of cumenyl polyoxyethylene ether of the present embodiment, comprises the steps:

[0038] 1) Add 36 parts of isopropenyl cumenol in the reactor, add 0.21 parts of metal sodium and 0.21 parts of metal potassium catalyst within 50 minutes, control the reaction temperature to 30-40 ° C, and the reaction time is 0.8 hours; Put the product into 300 parts of isopropenyl cumenol, replace it with nitrogen, raise the temperature to 90°C, feed 504 parts of ethylene oxide, control the reaction temperature to 90-105°C, and the reaction time is 5.5 hours; after the reaction, cool down to A cumenyl polyoxyethylene ether oligomer with a molecular weight of 350 was obtained by discharging at 70°C.

[0039] 2) Add 84 parts of cumenyl polyoxyethylene ether oligomers with a molecular weight of 350 obtained in step 1) in the reactor, add 1.5 parts of metal sodium and 1.5 parts of metal potassium catalyst within 50 minutes, and control the reaction The temperature ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com