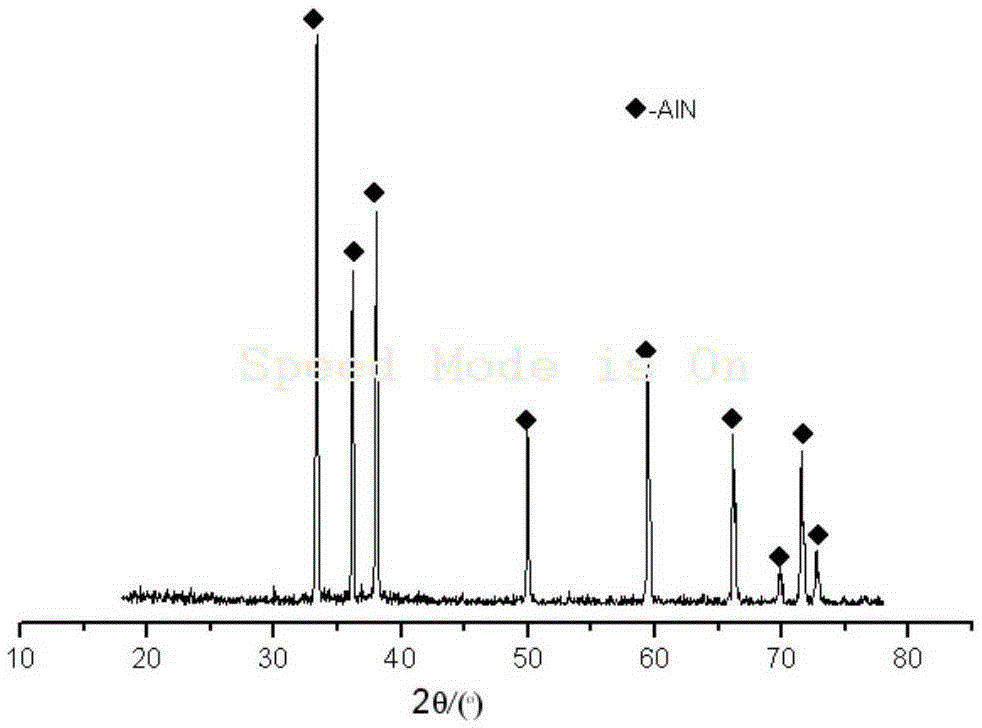

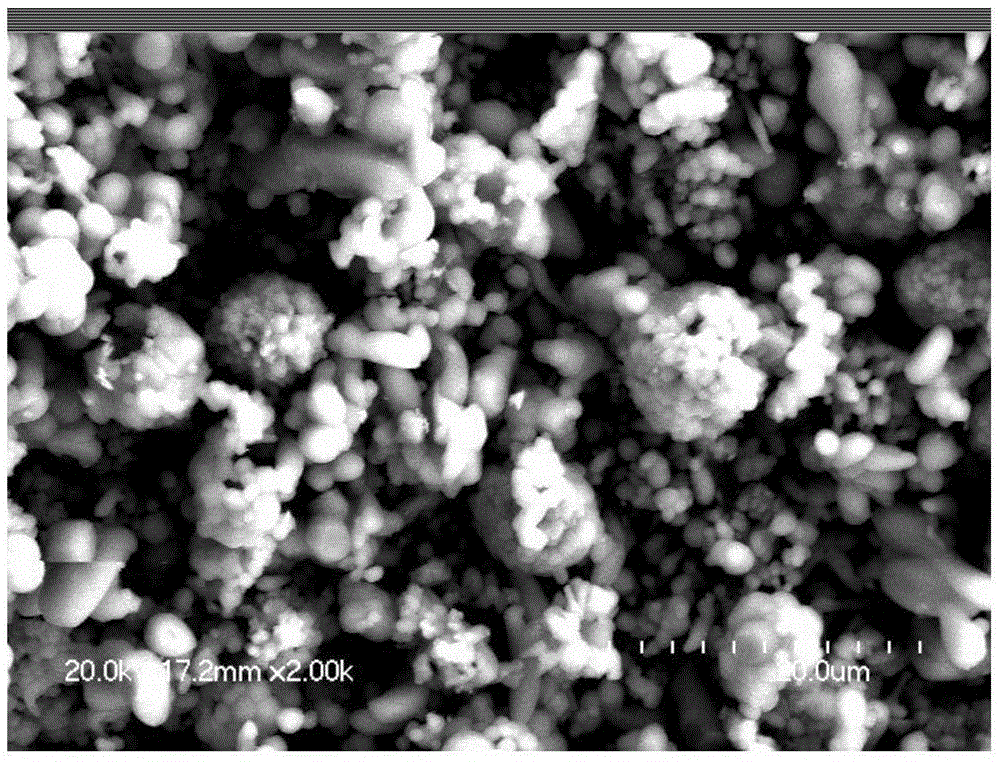

Method for compounding high-quality low-oxygen low-iron aluminium nitride powder

A synthesis method and technology of aluminum nitride, applied in nitrogen compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of short reaction time and high cost, and achieve the effects of short reaction time, low cost and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Use aluminum powder with a particle size of D50 of 10 μm and a purity greater than 99.9% as raw material, mix 2000g of aluminum powder with 5000g of aluminum nitride and 240g of ammonium chloride evenly, and sprinkle it on aluminum nitride with a length of 1 meter, a width of 0.2 meters, and a groove depth of 0.2 meters. In the ceramic sagger, then evenly sprinkle 20g of carbon powder with a purity greater than 99.9% on the surface of the mixed powder, place the aluminum nitride ceramic sagger in a high-pressure industrial reactor, and then vacuumize the high-pressure industrial reactor to 1 ×10-4MPa, after the vacuuming is completed, let the pretreated nitrogen gas (the pretreated nitrogen gas refers to the nitrogen gas whose purity is greater than 99.999% to remove oxygen, carbon dioxide, carbon monoxide and water vapor), the pressure is 5MPa, keep for 5min, ignite, Carry out self-propagating high-temperature synthesis, the synthesis temperature is greater than 2000°C,...

Embodiment 2

[0039] Use aluminum powder with a particle size of D50 of 10 μm and a purity greater than 99.9% as raw material, mix 2000g of aluminum powder with 5000g of aluminum nitride and 240g of ammonium chloride evenly, and sprinkle it on aluminum nitride with a length of 1 meter, a width of 0.2 meters, and a groove depth of 0.2 meters. In the ceramic sagger, the aluminum nitride ceramic sagger was placed in a high-pressure industrial reactor, and then the high-pressure industrial reactor was vacuumed to 1×10-4MPa, and after the vacuuming was completed, the pretreated nitrogen gas (pre- The treated nitrogen refers to nitrogen with a purity greater than 99.999% except oxygen, carbon dioxide, carbon monoxide and water vapor), the pressure is 5 MPa, kept for 5 minutes, ignited, and self-propagating high-temperature synthesis is carried out. The synthesis temperature is greater than 2000 ° C and the synthesis time is 10 to 12 minutes. , After the resulting composition is cooled to 20°C by a...

Embodiment 3

[0041] Use aluminum powder with a particle size of D50 of 10 μm and a purity greater than 99.9% as raw material, mix 2000g of aluminum powder with 5000g of aluminum nitride and 240g of ammonium chloride evenly, and sprinkle it on aluminum nitride with a length of 1 meter, a width of 0.2 meters, and a groove depth of 0.2 meters. In the ceramic sagger, the aluminum nitride ceramic sagger was placed in a high-pressure industrial reactor, and then the high-pressure industrial reactor was vacuumed to 1×10-4MPa, and after the vacuuming was completed, the pretreated nitrogen gas (pre- The treated nitrogen refers to nitrogen with a purity greater than 99.999% except oxygen, carbon dioxide, carbon monoxide and water vapor), the pressure is 5.5 MPa, kept for 5 minutes, ignited, and self-propagating high-temperature synthesis is carried out. The synthesis temperature is greater than 2000 ° C and the synthesis time is 10 ~ After 12 minutes, the obtained composite was cooled to 20°C by a wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com