A processing method for a multi-capacitance comb-tooth micro-accelerometer

A micro-accelerometer and processing method technology, applied in the direction of measurement of acceleration, speed/acceleration/impact measurement, and processes for producing decorative surface effects, etc., can solve the problem of poor control accuracy of wet corrosion, large detection capacitance area, detection capacitance Small area, etc., to meet the requirements of high-precision measurement, good size control, and large detection capacitance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The method of the present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0024] The following examples are only used to illustrate the present invention, but not to limit the present invention. Those skilled in the art may make various changes, substitutions and modifications without departing from the spirit and scope of the present invention, and therefore equivalent technical solutions also belong to the scope of the present invention.

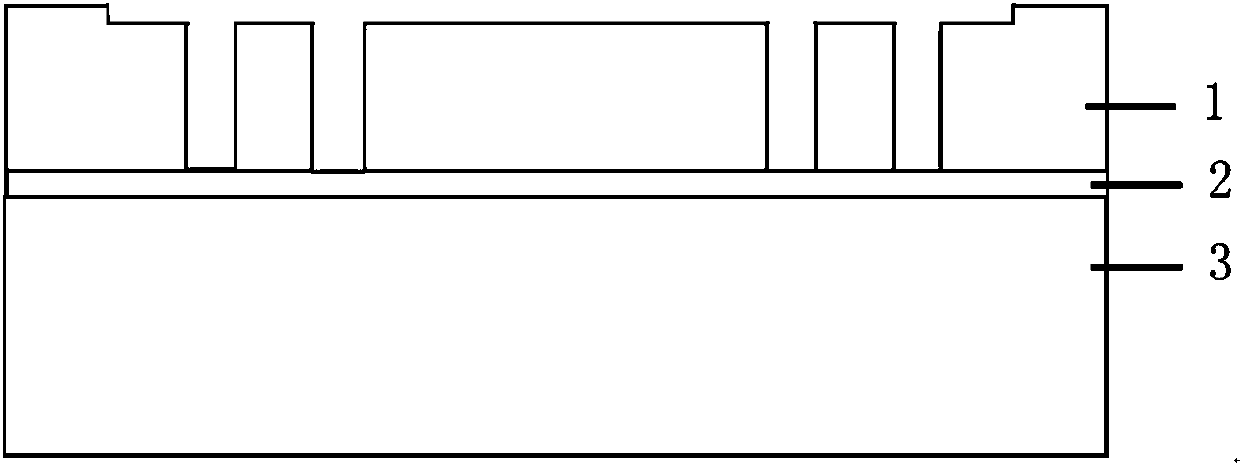

[0025] The raw material is SOI silicon wafer, and the SOI silicon wafer consists of structural layer 1, insulating layer 2 and substrate layer 3 from top to bottom; the thickness of structural layer 1 is 80 μm, N-type silicon, resistivity 0.01~0.1Ω / cm, crystal orientation; the thickness of the insulating layer 2 is 1 μm, and the material is silicon dioxide; the thickness of the substrate layer 3 is 450 μm, and it is N-type silicon.

[0026] The detection capacitance of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com