Screen-free type intelligent nanometer grinding system

A nano-grinding, screenless technology, applied in grain processing and other directions, can solve the problems of low separation efficiency, stable separation device and possible unfavorable operation, and can not solve the problem of secondary entrainment of powder, so as to achieve high output and excellent performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

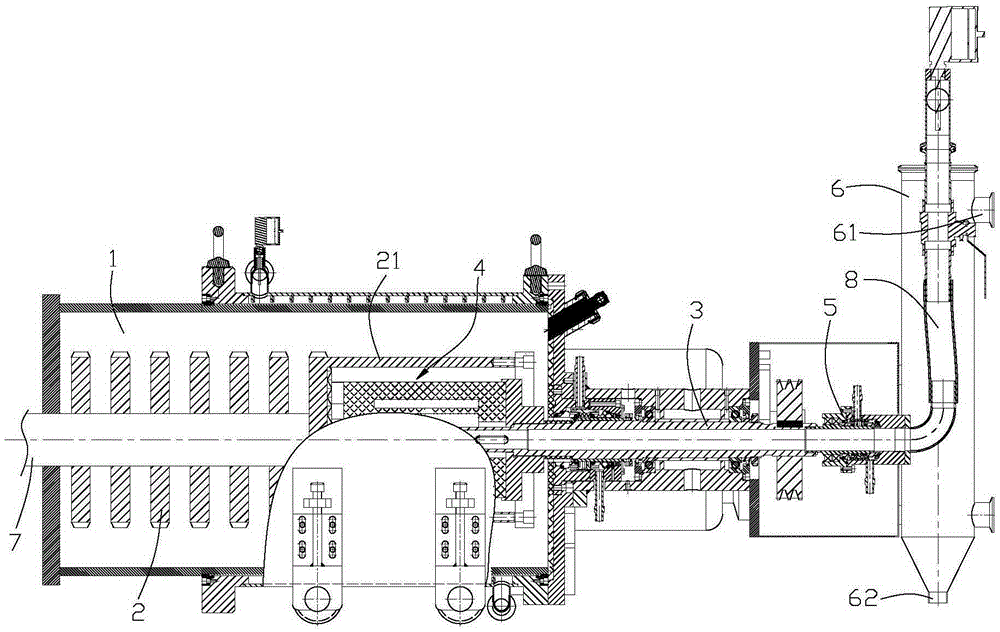

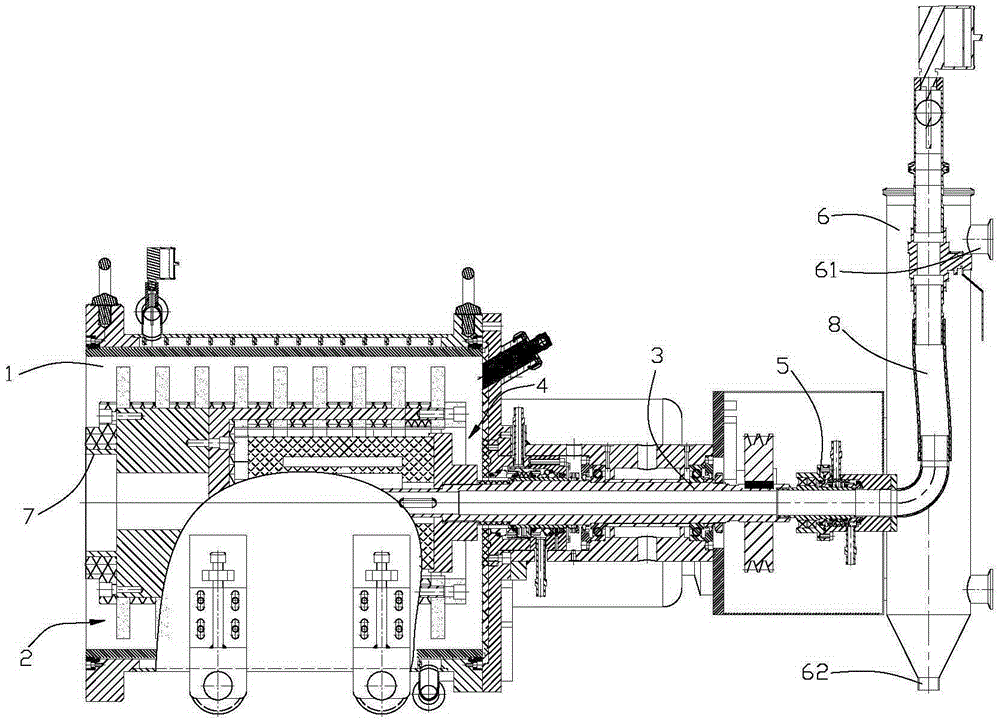

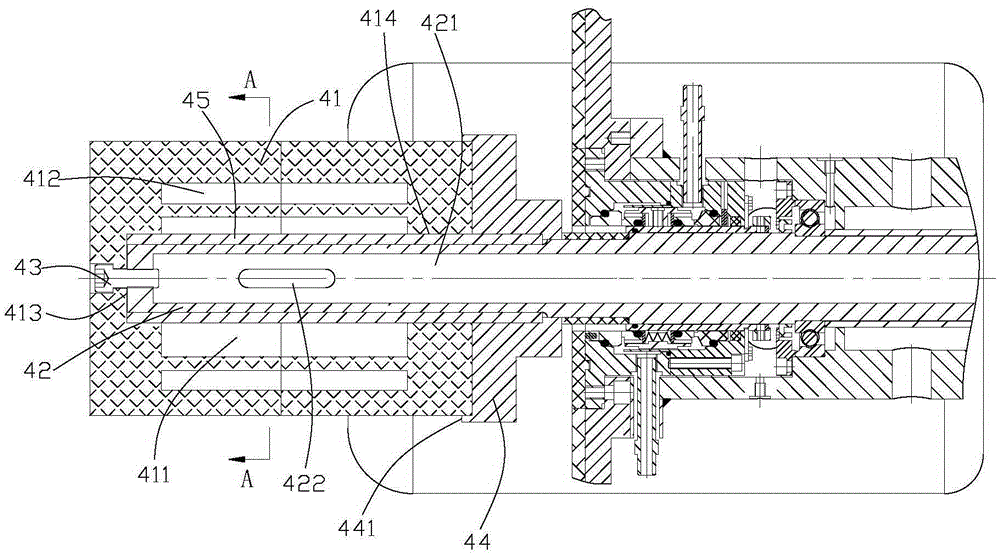

[0020] The following drawings introduce in detail the screenless intelligent nano-grinding system (PHNHonor) of the present invention, which includes a horizontally arranged grinding chamber 1 and a grinding rotor 2 arranged in the grinding chamber, and one end of a rotating hollow shaft 3 extends into the Grinding chamber, the hollow discharge shaft is equipped with a rotating separation device 4 driven by it, and the materials in the grinding chamber flow to the outer periphery of the rotating separation device after being hit by the grinding rotor and the grinding medium. Then, the grinding media and the large-grained materials after grinding are thrown out of the rotary separation device, and the materials with small particles after grinding overcome the centrifugal force and enter the rotary separation device under the action of feed pressure, and then flow into the discharge hollow shaft from the rotary separation device. , and then flow into the vertically set sedimentat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com