Manufacturing method of pnbzt film

A manufacturing method and thin-film technology, which is applied in chemical instruments and methods, semiconductor/solid-state device manufacturing, niobium compounds, etc., can solve problems such as the decrease of piezoelectric properties of PNbZT thin films, and achieve a roughly uniform composition distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0042] Next, examples of the present invention will be described in detail together with comparative examples.

[0043]

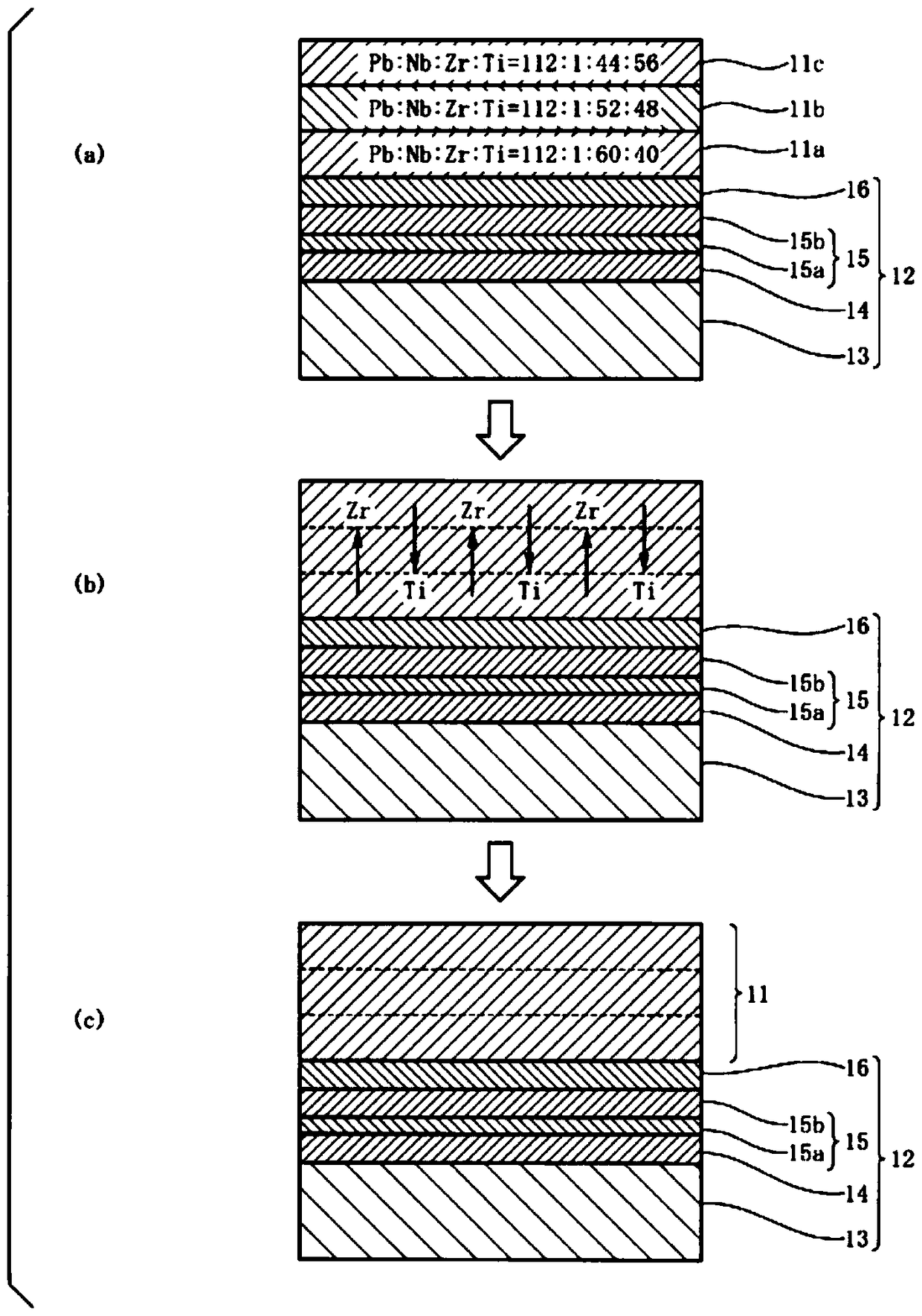

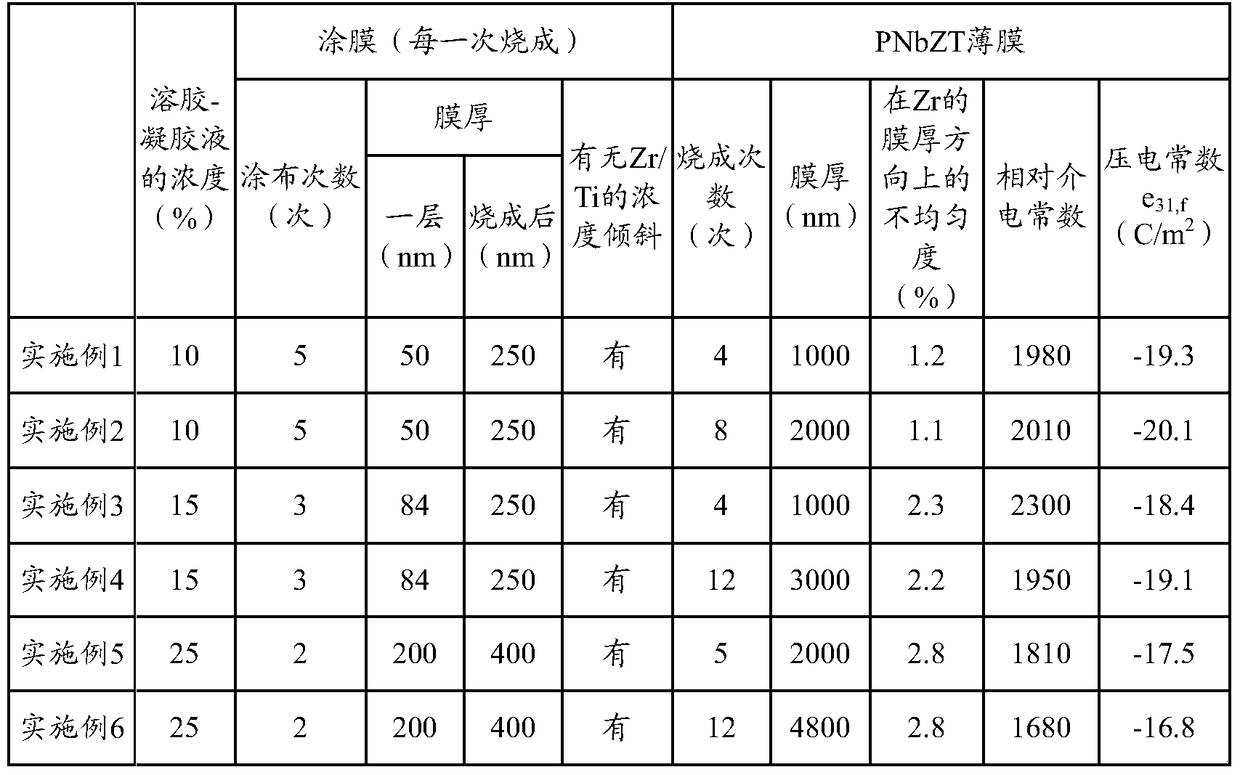

[0044] As the sol-gel solution used to form the PNbZT thin film, prepare a precursor concentration (Pb) with a metal composition ratio of 125 / 10 / 52 / 48 (Pb / Nb / Zr / Ti) and a solvent diluted with 1-butanol. The total of the source, the Nb source, the Zr source, and the Ti source) is a sol-gel solution (E1 solution manufactured by Mitsubishi Materials Corporation) adjusted to 15% by mass in terms of oxide. Here, let the ratio of Nb be higher than the composition formula Pb z Nb x Zr y Ti 1-y O 3 (02 Film and in the SiO 2 TiO x A lower electrode composed of a film and a Pt film, and a crystallization promoting layer is formed on the Pt film.

[0045] In addition, in this Comparative Example 1, and the following Examples 1 to 7 and Comparative Examples 2 to 6, if not particularly limited, a (100)-oriented PZT thin film was formed on the Pt film as a crystallization pro...

Embodiment 2

[0054] Except for the step of forming the PNbZT thin film that is fired once and repeated five times from the application of the first to fifth sol-gel solutions to the temporary firing, the total thickness is approximately An eight-layer PNbZT thin film of 2 μm (about 2000 nm) was formed on the crystallization promoting layer of the substrate. In the same manner as in Example 1, the PNbZT thin film was formed on the crystallization promoting layer of the substrate. The substrate on which the PNbZT thin film was formed was used as Example 2.

Embodiment 3、4 and 7

[0056] In addition to the concentration of the sol-gel solution, the number of coatings of the coating film per firing, the film thickness of one layer, the film thickness after firing, the Pt / Nb concentration ratio, and the Zr / Ti per coating film The PNbZT film was formed in the same manner as in Example 1, except that the concentration ratio of PNbZT film, the number of firing of the PNbZT film, and the film thickness of the PNbZT film (hereinafter referred to as various conditions) were changed as described in Tables 1 and 2.

[0057] The substrates on which the PNbZT thin film was formed in this manner were used as Examples 3, 4, and 7.

[0058] In addition, in Examples 3, 4, and 7, only three types of the first to third sol-gel solutions were prepared, and each sol-gel solution was used until the first to third coating films were formed, and then firing was performed. In this regard, in the following examples, in the same manner, a plurality of sol-gel liquids described in Tab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com