Manufacturing method of Zener diode and LED packaging device

A technology of Zener diodes and manufacturing methods, which is applied in the manufacture of electric solid-state devices, semiconductor devices, semiconductor/solid-state devices, etc., can solve the problems of complicated manufacturing process, high Zener cost, affecting production capacity and yield rate, etc., to reduce light absorption effect, good controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

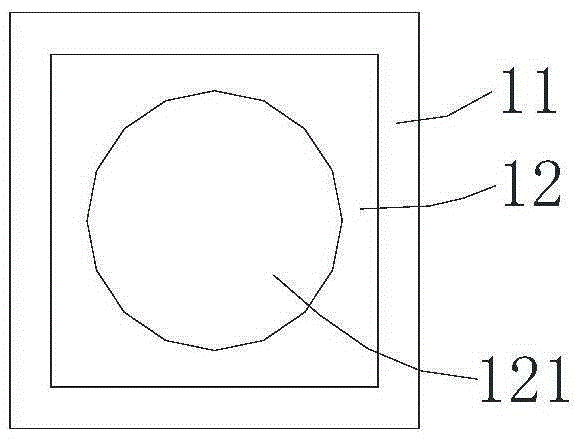

[0032] Such as figure 1 As shown, the fabrication method of the Zener diode includes:

[0033] Firstly, a temporary carrier is mounted on an ultraviolet light-permeable substrate, and the temporary carrier includes a first contact layer in contact with the substrate and a second contact layer in contact with the Zener diode.

[0034] The first contact layer has viscosity to facilitate bonding the temporary carrier on the substrate; the second contact layer has viscosity to facilitate bonding the Zener diode to the temporary carrier. Preferably, the viscosity of the first contact layer is greater than the viscosity of the second contact layer.

[0035] Then, Zener diodes 12 are evenly arranged on the second contact layer of the temporary carrier.

[0036] White reflective glue is coated on the temporary carrier evenly arranged with Zener diodes 12 and cured by heating, so that a white reflective glue layer 11 is formed on the surface of Zener diodes 12; wherein, the surface i...

Embodiment 2

[0044] The technical scheme of embodiment 2 is basically the same as embodiment 1, and its difference mainly lies in:

[0045] In this embodiment, a temporary carrier is mounted on a substrate, and the temporary carrier includes a first contact layer in contact with the substrate and a second contact layer in contact with the Zener diode. Wherein, the substrate is not limited to an ultraviolet light-permeable substrate.

[0046] In this embodiment, the viscosity of the first and second contact layers is reduced or eliminated by heating, preferably, the viscosity of the first and second contact layers is reduced to 80% of the initial viscosity by heating to above 180°C.

[0047] Among them, the hardness of the white reflective adhesive is Shore 50D, and the reflectivity is 90%.

Embodiment 3

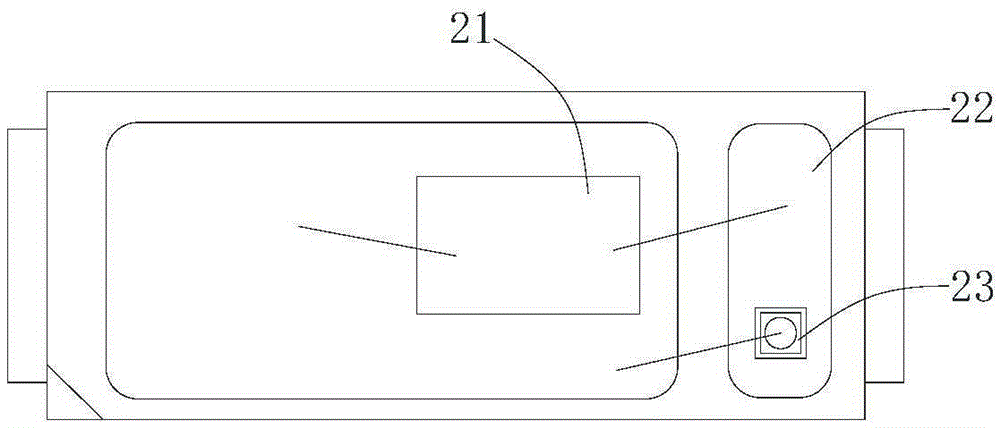

[0049] Such as figure 2 Shown is an LED packaging device of the present invention, which includes Zener diodes manufactured by the methods described in Embodiment 1 and Embodiment 2.

[0050] Specifically, in the support 22, the light-emitting diode 21 and the zener diode 23 with a reflective adhesive layer prepared by the manufacturing method of the present invention are fixed; It is electrically connected to the positive and negative poles of the bracket 22; finally, the packaging is completed through the steps of dispensing, baking, testing, and binning.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com