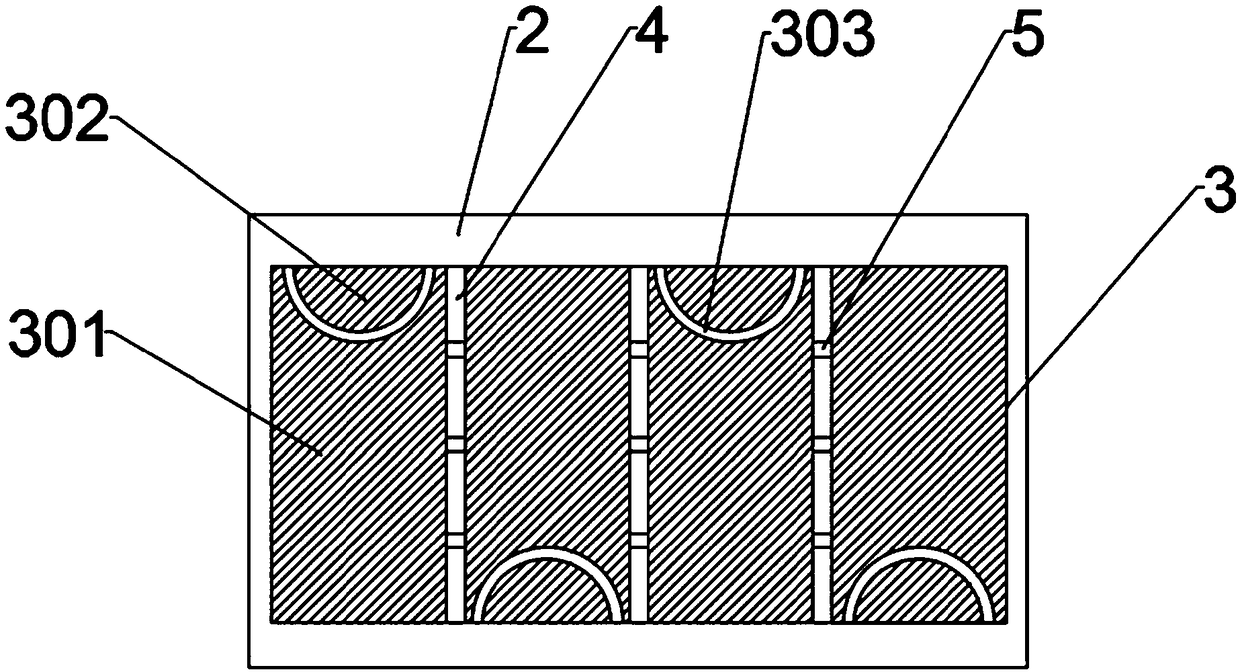

Semiconductor diode chip structure and lamp illumination component thereof

A chip structure and semiconductor technology, applied in the direction of semiconductor devices, electrical components, cooling/heating devices of lighting devices, etc., can solve the problems of chip short circuit, affecting the accuracy of packaging, solder overflow, etc., and achieve the effect of improving luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

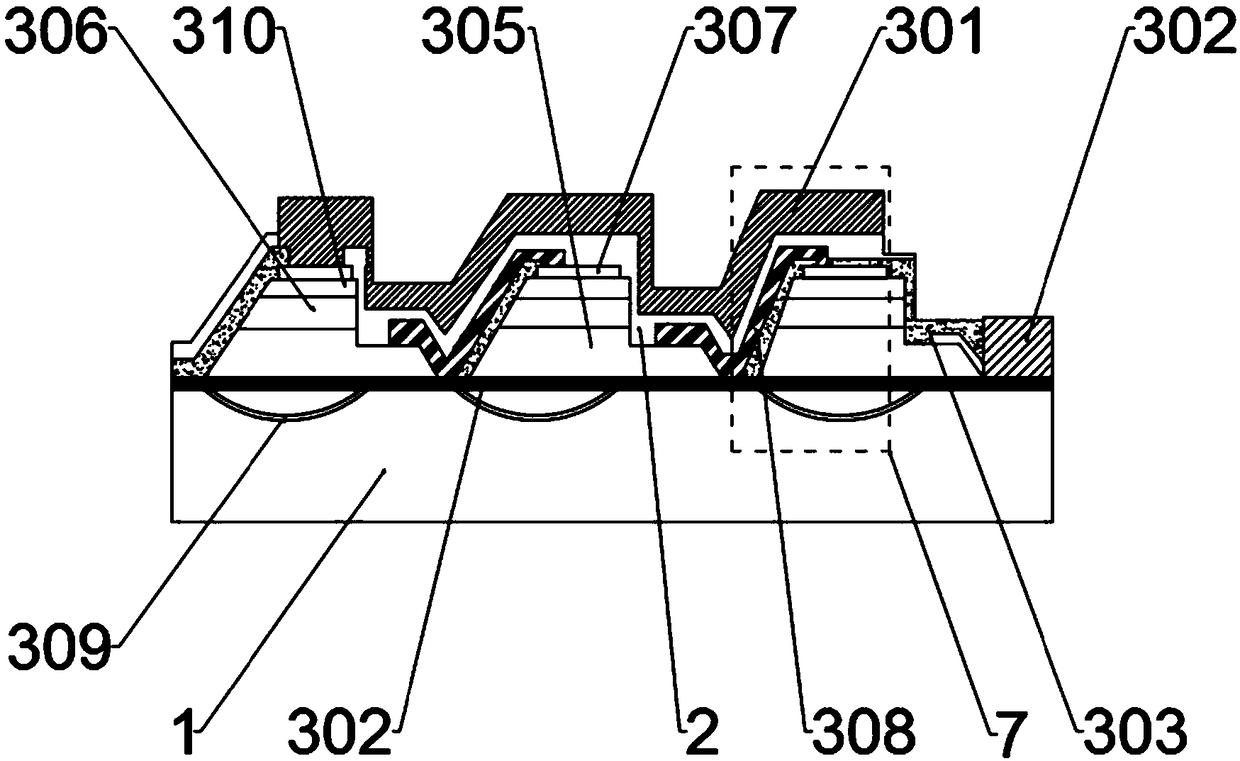

[0061] Such as Figure 10 As shown, the present invention also provides a semiconductor diode chip packaging manufacturing method, comprising the following steps:

[0062] S100, welding the metal heat sink to the package bracket, and fixing the chip position.

[0063] S200. The packaging bracket with the chip installed is sent to the reflow furnace for reflow soldering. During the reflow soldering, the temperature in the reflow furnace rises rapidly to the preheating temperature, and then continues to heat up to the melting temperature of the solder to produce a melting reaction. Finally, the temperature is rapidly lowered. .

[0064] S300. Connect the positive and negative poles of the chip with the metal pins on the package support, and weld the metal pins on the package support.

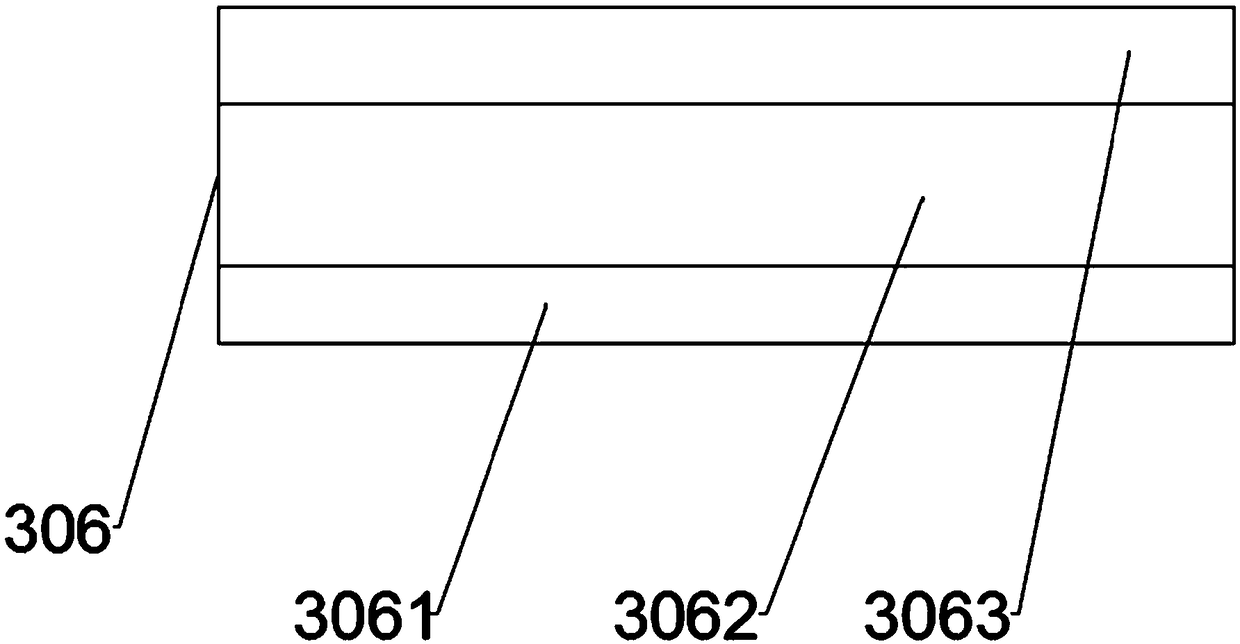

[0065] S400, dispensing the hemispherical silica gel on the surface of the chip, and installing the overall connection structure of the reflective cup and the negative lens.

[0066] Wherein st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com