Method for preparing photochromic fiber and photochromic fabric

A technology of photosensitive discoloration and photosensitive discoloration fiber, which is applied in the field of photosensitive fiber and its application in home textile products. good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

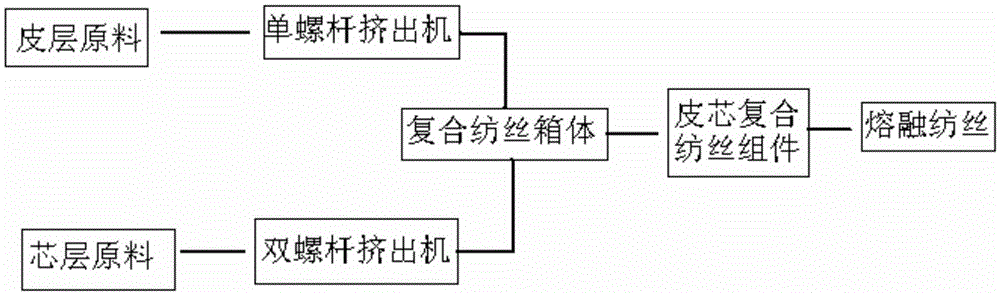

[0032] This embodiment discloses a method for preparing photochromic fibers, specifically:

[0033] The photochromic fiber is a fiber with a skin-core structure prepared by a blending melt spinning method, and the mass of the core layer is 35% by weight of the mass of the photochromic fiber, wherein the raw materials of the skin layer include polyester resin and polyester resin. Antioxidant with a resin mass percentage of 5%; the core layer raw materials include polyester resin, photochromic particles with a mass percentage of 3% of the polyester resin, and an oxidant with a mass percentage of 8% of the polyester resin . The antioxidant is antioxidant 1010.

[0034] Specifically, the photochromic particles are indoline spiropyran.

[0035] Specifically, the blending melt spinning method comprises the following steps:

[0036] 1) Add the raw material of the skin layer to the single-screw extruder for extrusion; the temperature of each zone of the single-screw extruder is: 12...

Embodiment 2

[0045] This embodiment discloses a method for preparing photochromic fibers, specifically:

[0046] The photochromic fiber is a fiber with a skin-core structure prepared by a blending melt spinning method, and the mass of the core layer is 40 wt% of the mass of the photochromic fiber, wherein the raw materials of the skin layer include polyester resin and polyester resin. Antioxidant with a resin mass percentage of 5%; the core layer raw materials include polyester resin, photochromic particles with a mass percentage of 7% of the polyester resin, and an oxidant with a mass percentage of the polyester resin of 6% . The photochromic particles are indoline spiropyran. The antioxidant is antioxidant 1010.

[0047]Specifically, the blending melt spinning method comprises the following steps:

[0048] a) Add the raw material of the skin layer into the single-screw extruder for extrusion; in step a), the temperature of each zone of the single-screw extruder is: 123°C in zone I, 12...

Embodiment 3

[0057] This embodiment discloses a method for preparing photochromic fibers, specifically:

[0058] The photochromic fiber is a fiber with a skin-core structure prepared by a blending melt spinning method, and the mass of the core layer is 45 wt% of the mass of the photochromic fiber, wherein the raw materials of the skin layer include polyester resin and polyester resin. Antioxidant with a resin mass percentage of 6%; the core layer raw materials include polyester resin, photochromic particles with a mass percentage of 8% of the polyester resin, and an oxidant with a mass percentage of 7% of the polyester resin . The photochromic particles are indoline spiropyran. The antioxidant is antioxidant 1010.

[0059] The blended melt spinning method comprises the following steps:

[0060] 1) The skin layer raw material is added to the single-screw extruder for extrusion; the temperature of each zone of the single-screw extruder in step 1) is: 121°C in zone I, 125°C in zone II, 130...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com