Polymer cement waterproof paint and preparing method thereof

A waterproof coating and polymer technology, applied in the direction of coating, can solve the problems of low emulsion stability and phase separation, and achieve excellent low-temperature flexibility, waterproof performance, and good mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

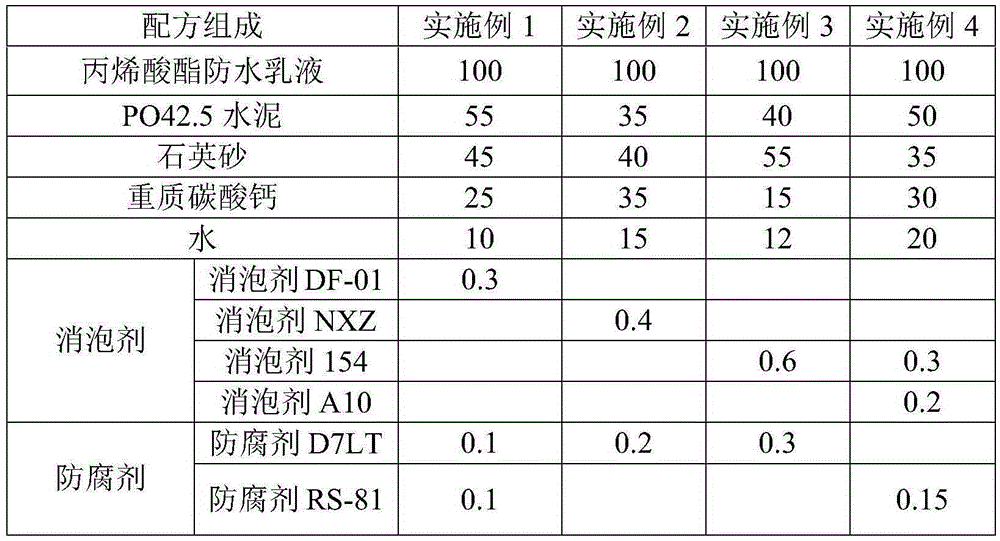

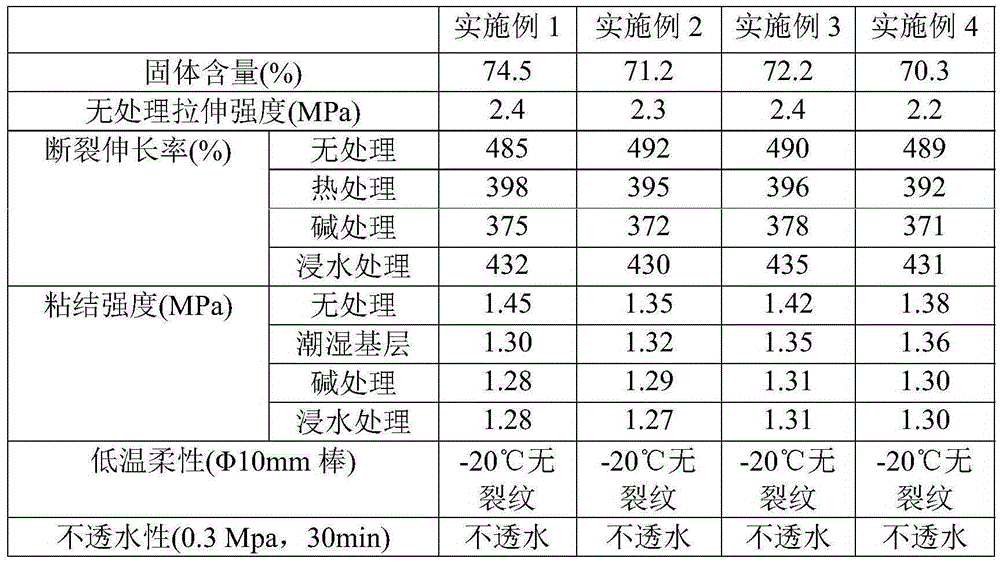

Examples

Embodiment 1

[0028] 1) Preparation of acrylate waterproof emulsion:

[0029] 1.1) In parts by weight, take 2 parts of emulsifier (DSB) and 50 parts of water in an emulsification kettle, stir, and add 15 parts of acrylic acid monomer after the emulsifier dissolves (from 10 parts of butyl acrylate and 5 parts of propylene isooctyl ester) to carry out emulsion polymerization, the reaction temperature is 80 ℃, and the reaction time is 30min to obtain a pre-emulsion;

[0030] 1.2) Take 0.2 parts of emulsifier (DSB) and 9 parts of water in the reaction kettle, raise the temperature to 90°C, add 60 parts of pre-emulsion, 0.5 parts of initiator (sodium persulfate) and 2 parts of silane Combined agent KBM-503, heat preservation reaction for 2 hours, then lower the temperature to 75°C and heat preservation reaction for 30 minutes, then lower to room temperature, adjust the pH value of the reactant to 8 with disodium hydrogen phosphate, and filter to obtain an acrylate waterproof emulsion;

[0031] ...

Embodiment 2

[0033] 1) Preparation of acrylate waterproof emulsion:

[0034] 1.1) In parts by weight, take 5 parts of emulsifier (0.5 part of emulsifier OP-10 and 0.5 part of emulsifier DSB) and 70 parts of water in the emulsification kettle, stir, and add after the emulsifier is dissolved 25 parts of acrylic acid monomers (composed of 10 parts of butyl acrylate, 5 parts of propylene isooctyl and 10 parts of methacrylic acid) were emulsion polymerized at a reaction temperature of 65°C and a reaction time of 60 minutes to obtain a pre-emulsion;

[0035] 1.2) Take 1.0 parts of emulsifier (from 0.5 parts of emulsifier OP-10 and 0.5 parts of emulsifier DSB) and 8 parts of water into the reaction kettle, heat up to 85 ° C, add 55 parts of pre-emulsion, 0.3 1 part of initiator (sodium persulfate) and 4 parts of silane coupling agent KBM-503, heat preservation reaction for 2 hours, then lower the temperature to 70°C and heat preservation reaction for 40 minutes, then lower to room temperature, ad...

Embodiment 3

[0038] 1) Preparation of acrylate waterproof emulsion:

[0039] 1.1) By weight, take 8 parts of emulsifier (emulsifier OP-10) and 60 parts of water in the emulsification tank, stir, and add 10 parts of acrylic acid monomer (butyl acrylate) after the emulsifier is dissolved Perform emulsion polymerization, the reaction temperature is 75°C, and the reaction time is 40min to obtain a pre-emulsion;

[0040] 1.2) Take 0.5 parts of emulsifier (emulsifier OP-10) and 10 parts of water in the reactor, heat up to 88 ° C, add 50 parts of pre-emulsion, 0.3 parts of initiator (ammonium persulfate) and 4 1 part of silane coupling agent KBM-503, heat preservation reaction for 1.5h, then lower the temperature to 65°C and heat preservation reaction for 30min, then lower to room temperature, adjust the pH value of the reactant to 8.5 with sodium dihydrogen phosphate, filter to obtain acrylate waterproof emulsion ;

[0041] 2) Take by weighing 100 parts of acrylate waterproof emulsion, 40 part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com