A light-converting agricultural film and its preparation method and application

A technology of light-converting agricultural film and light-converting agent, which is applied in the field of agricultural light-light conversion functional materials, can solve the problems of poor absorption wavelength matching, slow attenuation of light-conversion intensity, and short fluorescence lifetime, etc., so as to reduce dust pollution and achieve excellent luminescence. Good performance and spectral matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

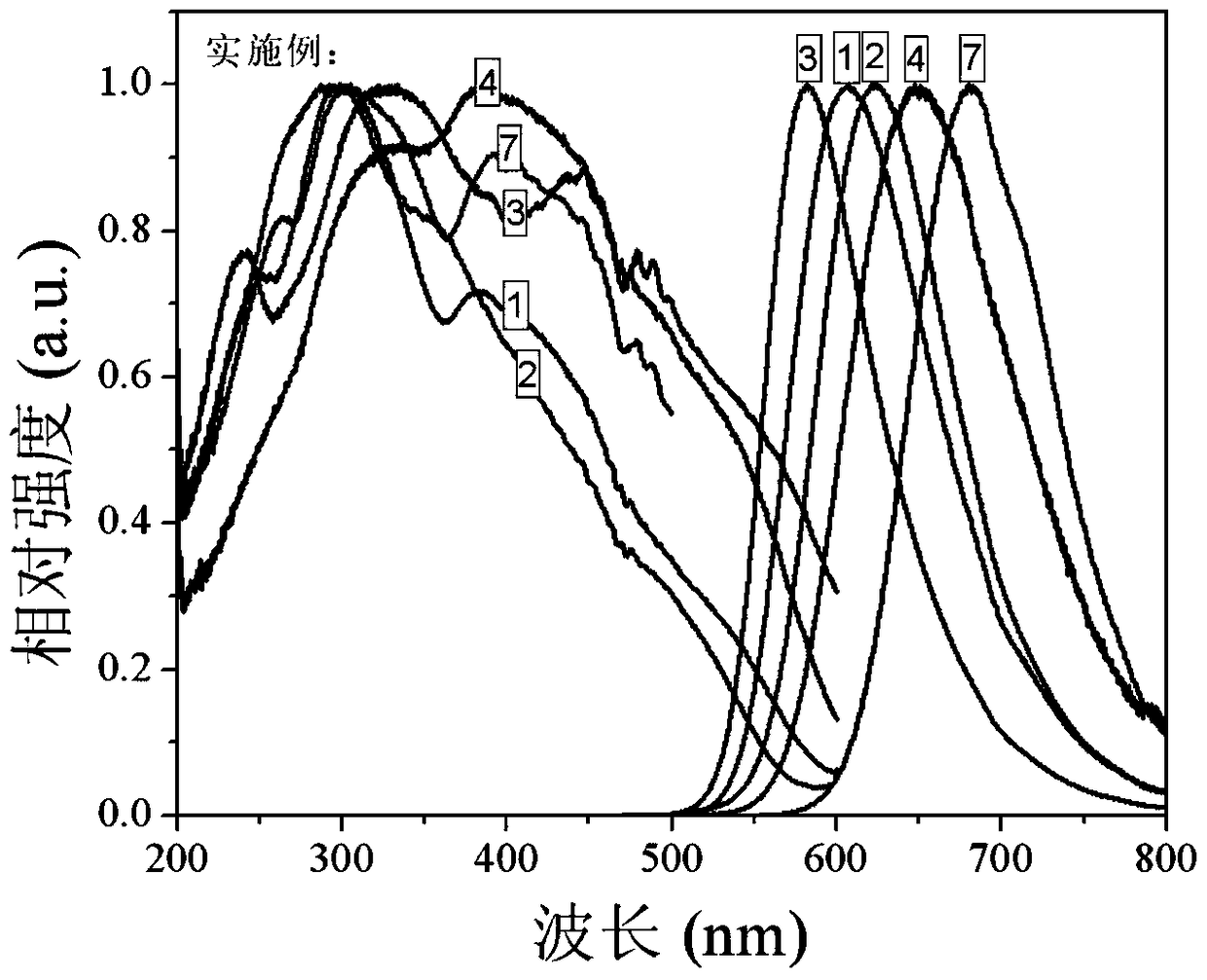

[0047] Embodiment 1: Nitride red light conversion agent Ca 1.96 Si 5 N 8 : Preparation of 0.04Eu

[0048] According to the stoichiometric ratio, accurately weigh 1.96mol calcium powder, 5mol silicon powder, and 0.04mol europium powder, and grind them in an agate mortar for 20 minutes; after mixing the raw materials evenly, put them into a boron nitride crucible and place them in a high-temperature furnace for melting ; In the melting stage, the inert atmosphere is argon atmosphere, the air flow rate is 100mL / min, the high temperature furnace is raised to 900°C at a rate of 50°C / min, and the temperature is kept for 1.5h. After natural cooling in the high-temperature furnace at room temperature, the obtained precursor was milled by a wet ball mill for 1 h, and the powder sample was transferred to a tube furnace for roasting; during the roasting stage, the protective atmosphere was nitrogen atmosphere, the air flow rate was 80 mL / min, and the tube furnace was heated at 5 °C. T...

Embodiment 2

[0049] Example 2: Nitride red light conversion agent Sr 1.96 Si 5 N 8 : Preparation of 0.04Eu

[0050] According to the stoichiometric ratio, accurately weigh 1.96mol strontium powder, 5mol silicon powder, and 0.04mol europium powder, and grind them in an agate mortar for 20 minutes; after mixing the raw materials evenly, put them into a boron nitride crucible and place them in a high-temperature furnace for melting ; In the melting stage, the inert atmosphere is argon atmosphere, the air flow rate is 100mL / min, the high temperature furnace is raised to 900°C at a rate of 50°C / min, and the temperature is kept for 1.5h. After natural cooling in the high-temperature furnace at room temperature, the obtained precursor was milled by a wet ball mill for 1 h, and the powder sample was transferred to a tube furnace for roasting; during the roasting stage, the protective atmosphere was nitrogen atmosphere, the air flow rate was 80 mL / min, and the tube furnace was heated at 5 °C. Th...

Embodiment 3

[0051] Example 3: Nitride red light conversion agent Ba 1.96 Si 5 N 8 : Preparation of 0.04Eu

[0052] According to the stoichiometric ratio, accurately weigh 1.96mol of barium powder, 5mol of silicon powder, and 0.04mol of europium powder, and grind them in an agate mortar for 20 minutes; after mixing the raw materials evenly, put them into a boron nitride crucible and place them in a high-temperature furnace for melting ; In the melting stage, the inert atmosphere is argon atmosphere, the air flow rate is 100mL / min, the high temperature furnace is raised to 900°C at a rate of 50°C / min, and the temperature is kept for 1.5h. After natural cooling in the high-temperature furnace at room temperature, the obtained precursor was milled by a wet ball mill for 1 h, and the powder sample was transferred to a tube furnace for roasting; during the roasting stage, the protective atmosphere was nitrogen atmosphere, the air flow rate was 80 mL / min, and the tube furnace was heated at 5 °...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com