A paper honeycomb composite panel with expandable strong bonding and high sound absorption and its manufacturing method

A manufacturing method and technology of paper honeycomb, which is applied in the field of expandable paper honeycomb composite board and its manufacture, can solve the problems of uneven product skin, insufficient plumpness of molded parts, exposed glass fiber, etc. Effect of sound absorption and peel strength increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

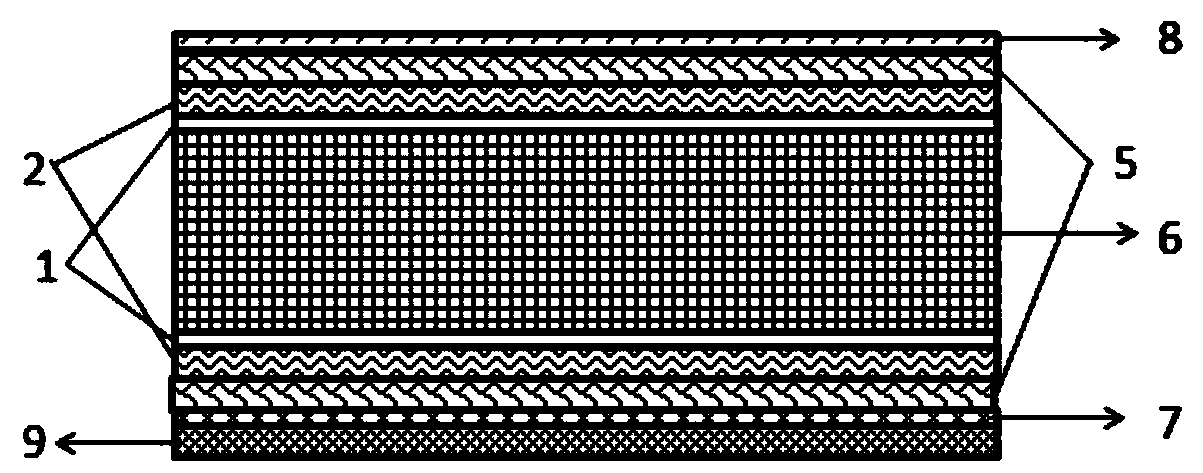

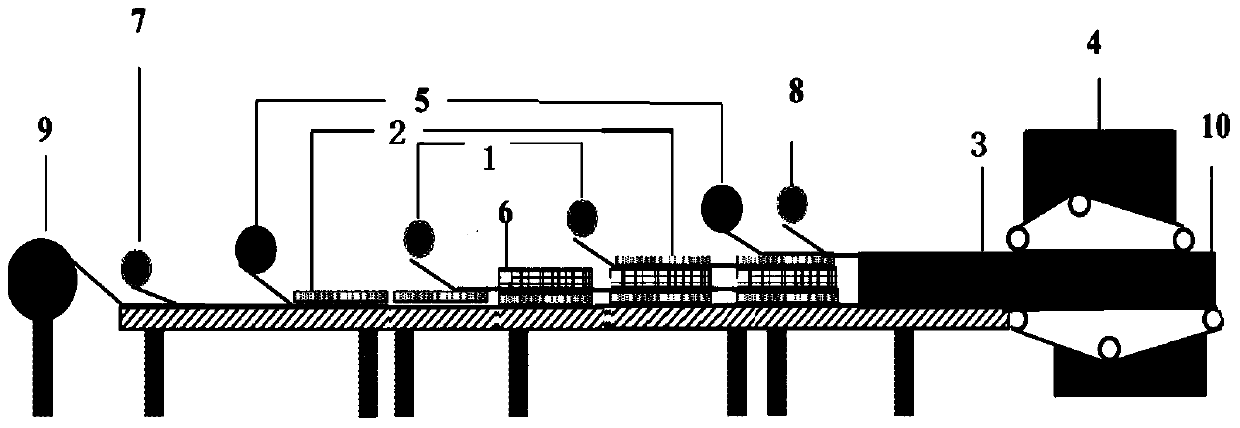

[0032] figure 1 It is a schematic diagram of the structure of the paper honeycomb composite board;

[0033] A kind of paper honeycomb composite panel with strong bonding and high sound absorption, which can be unwound by 50g / m from bottom to top 2 Black spunlace fabric, 10g / 10min modified polyethylene film A7, place prepreg 5, then unwind glass fiber reinforced polypropylene fiber composite material GMT2, 20g / 10min modified polyethylene film B1, place 5mm thick The regular hexagonal honeycomb core material is compounded by unwinding 20g / 10min modified polyethylene film B1, glass fiber reinforced polypropylene fiber composite material GMT2, placing prepreg 5, and finally unwinding 30g / 10min polyethylene film C8 .

[0034] The structure of prepreg 5 is as follows:

[0035] It is composed of modified polypropylene film with a melt index of 50g / 10min and glass fibers with a linear density of 2280-2520tex, 8 beams, and a length of 5mm at a ratio of 5:5.

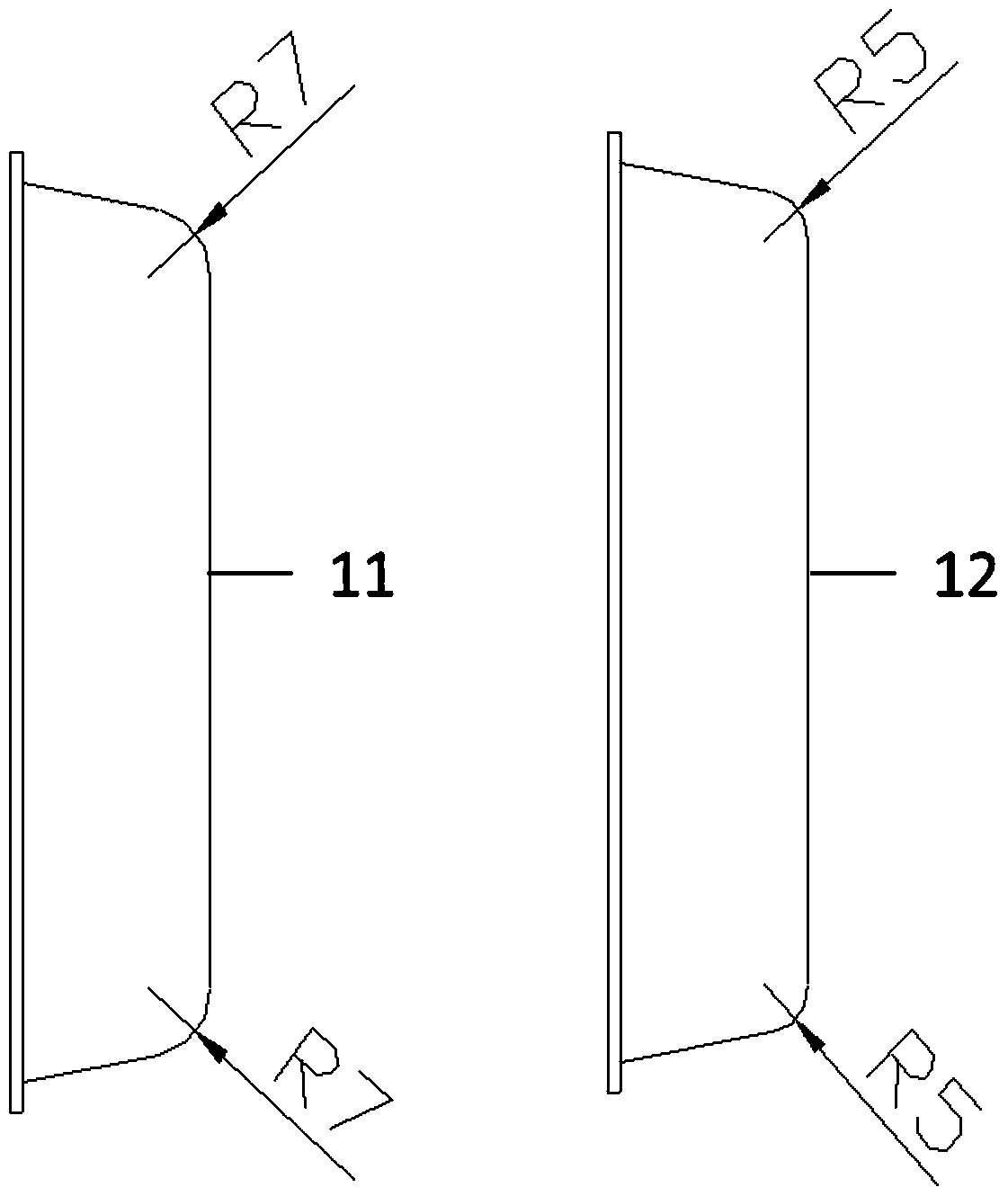

[0036] The structure o...

Embodiment 2

[0043] A kind of paper honeycomb composite board with strong bonding and high sound absorption, which can be unwound by 120g / m from bottom to top 2 Black hot-rolled polyethylene terephthalate non-woven fabric, 10g / 10min modified polypropylene film A7, place prepreg 5, and then unwind glass fiber reinforced polypropylene fiber composite material GMT2, 40g / 10min modified polypropylene film B1, place 25mm thick triangular honeycomb core material 6, unwind 40g / 10min modified polypropylene film B1, glass fiber reinforced polypropylene fiber composite material GMT2, place prepreg 5, and finally put Roll 50g / m 2 Composite polypropylene film C8.

[0044] The structure of prepreg 5 is as follows:

[0045] It is made of modified polypropylene film with a melt index of 100g / 10min and glass fibers with a linear density of 2280-2520tex, 8 beams, and a length of 5mm at a ratio of 5:5.

[0046] The structure of glass fiber reinforced polypropylene fiber composite GMT2 is as follows:

[...

Embodiment 3

[0053] A kind of paper honeycomb composite board with strong bonding and high sound absorption, which can be unwound by 100g / m from bottom to top 2 Black hot-rolled polyethylene terephthalate non-woven fabric, 5 / min modified ethylene-acrylic acid copolymer film A7, place prepreg 5, and then unwind glass fiber reinforced polypropylene fiber composite material GMT2 , 50g / 10min modified ethylene-acrylic acid copolymer film B1, place corrugated honeycomb core material 6 with a thickness of 15mm, unwind 50g / 10min modified ethylene-acrylic acid copolymer film B1, glass fiber reinforced polypropylene fiber composite material GMT2, place prepreg 5, and finally unwind 50g / m 2 Modified polyethylene film C8 composite.

[0054] The structure of prepreg 5 is as follows:

[0055] Modified polypropylene film with a melt index of 75g / 10min and glass fiber with a linear density of 2280-2520tex, 8 beams, and a length of 5mm in a ratio of 5:5.

[0056] The structure of glass fiber reinforced ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com