Non-noble metal oxide combustion catalyst, and preparation method and use thereof

A technology for burning catalysts and non-precious metals, which is used in catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc. Harsh and other problems, to achieve good catalytic activity and hydrothermal stability, high catalytic activity and hydrothermal stability, beneficial to large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

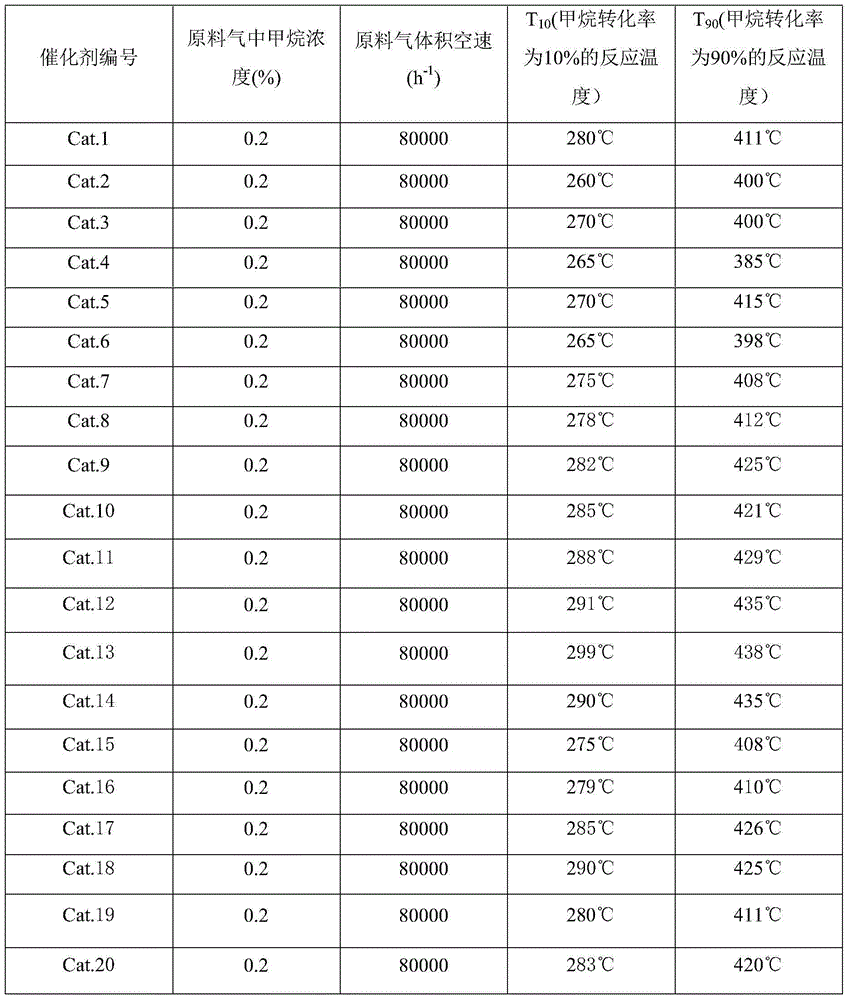

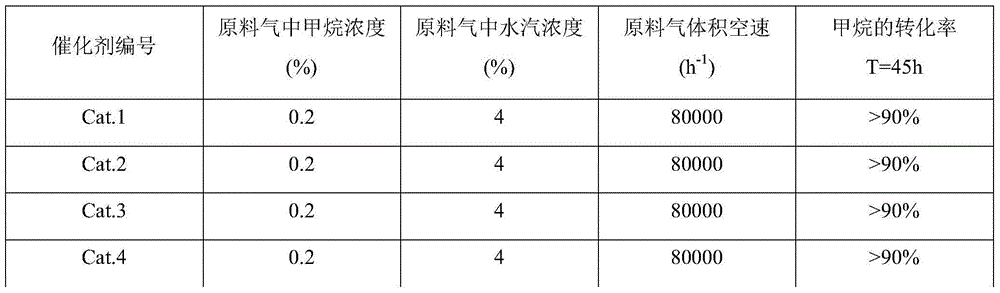

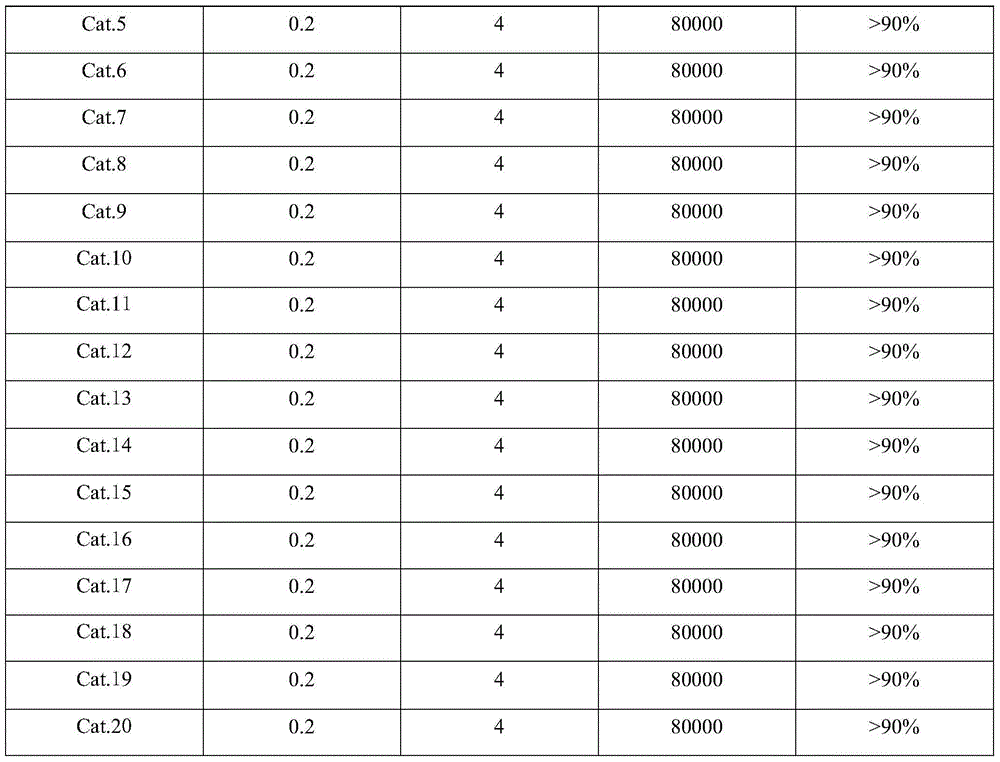

Embodiment 1

[0041] Take 15mmol of cobalt nitrate hexahydrate, 1g of polyvinylpyrrolidone (PVP), 80ml of ammonia water (mass concentration is 30%), stir magnetically at room temperature for half an hour, and place this mixture in a 120ml internally agglomerated polytetrafluoroethylene stainless steel for reaction. Seal the kettle and place it in an oven at 80°C for 8h. Then, the reacted sample was subjected to suction filtration, washed with deionized water until neutral, and a filter cake was obtained. The filter cake was placed in an oven at 110 °C and dried for 5 h. The dried sample was placed in a muffle furnace and calcined at 500°C for 2 hours to obtain a combustion catalyst of tricobalt tetroxide, numbered Cat.1.

Embodiment 2

[0043] Take 22.5mmol of cobalt chloride hexahydrate, 60mmol of urea, 0.5000g of cetyl ammonium bromide, add 80ml of deionized water, and stir magnetically at room temperature for half an hour to form a homogeneous solution. Seal it in a tetrafluoroethylene stainless steel reaction kettle, place it in an oven, and keep it at 160°C for 12h. Then, the reacted sample was subjected to suction filtration, washed with deionized water and ethanol until neutral, and a filter cake was obtained. The filter cake was placed in an oven at 80 °C and dried for 8 h. The dried sample was placed in a muffle furnace and calcined at 350°C for 4 hours to obtain a combustion catalyst of tricobalt tetroxide, numbered Cat.2.

Embodiment 3

[0045] Take 20mmol of cobalt sulfate hexahydrate, 60mmol of hexamethylenetetramine, add 1.000g of cetyl ammonium bromide, add 60ml of ethanol, 15ml of deionized water, and stir magnetically at room temperature for half an hour to obtain a uniform solution. Put it in a polytetrafluoroethylene stainless steel reaction kettle with a volume of 120ml and seal it, put it in an oven, and keep it at 120°C for 18h. Then, the reacted sample was subjected to suction filtration, washed with deionized water and absolute ethanol until neutral to obtain a filter cake, which was placed in a vacuum oven at 60° C. and dried for 10 h. Finally, the dried sample was placed in a muffle furnace and calcined at 400°C for 3 hours to obtain a combustion catalyst of tricobalt tetroxide, numbered Cat.3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com