Processing method of whole potato flour and nutrient vegetable crackers

A kind of technology of potato flour and processing method, which is applied in the direction of dough processing, baking, baked food, etc., to achieve the effect of easy industrial production, simple operation, and strong potato flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1. Raw material processing:

[0029] 1.1 Preparation of whole potato powder: fresh potato→wash, peel, slice→protect color→soak calcium→vacuum drying (4-6h)→hot air drying→add emulsifier (glyceryl monostearate)→crush, pass 60 mesh Sieve → whole potato powder;

[0030] 1.2 Weigh 30 portions of fresh eggs, remove the shells, take the whole egg liquid, 10 portions of white sugar, 50 portions of potato powder, and 5 portions of oat bran, crush them through a 60-mesh sieve, and set aside;

[0031] 1.3 Heat 30 parts of milk to boiling, then cool to room temperature, set aside;

[0032] 1.4: Preparation of dehydrated vegetables

[0033] Choose fresh and high-quality cabbage, carrots, and spinach that are free of mechanical damage and disease and insect pests, and then cut the cleanly selected cabbage and carrots into 1cm×1cm squares, and cut the spinach to 2-4cm short sections; cut the processed cabbage ,carrot. Spinach was blanched in boiling water at 100°C for 2 minutes. After takin...

Embodiment 2

[0041] A processing method of potato full-powder nutritious vegetable shortbread specifically includes the following steps:

[0042] A: Raw material processing

[0043] A1: Weigh 25 portions of fresh eggs, remove the shells and take the whole egg liquid, 7 portions of white sugar, 80 portions of potato powder, and 8 portions of oat bran, respectively, crush them through a 60-mesh sieve for use;

[0044] A2: Heat 40 parts of milk to boiling, then cool to room temperature, set aside;

[0045] A3: Preparation of dehydrated vegetables

[0046] Mix the dehydrated cabbage, carrots, and spinach, crush them at room temperature, pass through a 60-mesh sieve, and set aside;

[0047] B: Mixing of ingredients

[0048] Mix the prepared white sugar with 7 parts of water and stir until the sugar melts. Add the whole potato powder, 8 parts salt, 6 parts vegetable oil, and then add 50 parts dehydrated vegetable powder, and stir slowly while adding the whole egg liquid. Then evenly sprinkle 25 parts of bl...

Embodiment 3

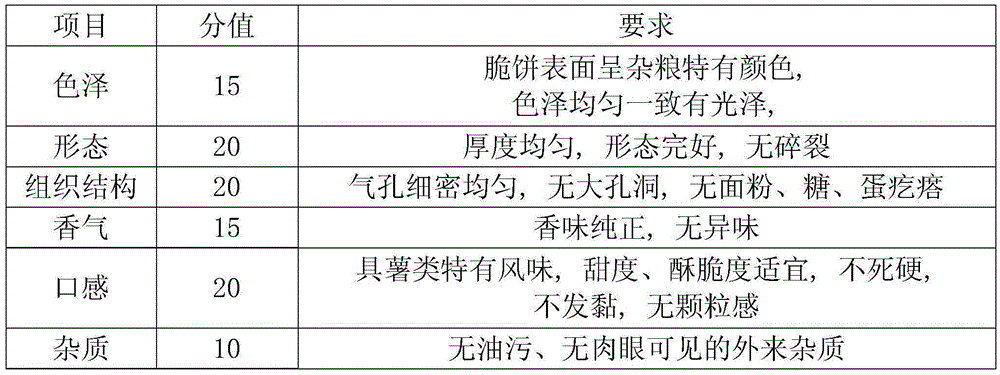

[0054] Sensory evaluation test of a kind of nutritious vegetable shortbread with potato flour

[0055] The sensory evaluation indicators of multi-grain shortbread include six aspects of color, shape, tissue structure, aroma, taste and impurities. The potato full-powder nutritious vegetable shortbread prepared in Example 1 and Example 2 of the present invention is selected for comparison with commercially available traditional shortbread. For evaluation, see Table 1 for specific scoring standards.

[0056] Table 1 Sensory evaluation standards for multigrain shortbread

[0057]

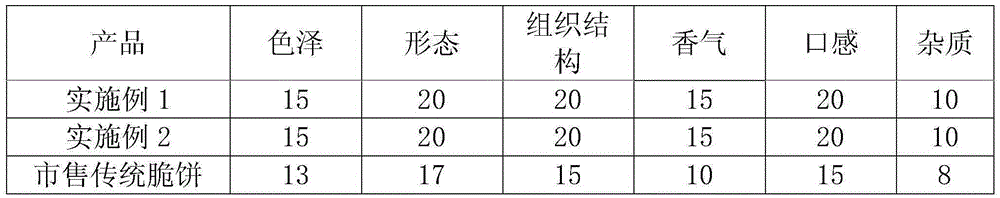

[0058] Table 2 Specific scoring results

[0059]

[0060] It can be seen from Table 1 that the potato full-powder nutritious vegetable shortbread prepared in Example 1 and Example 2 of the present invention has a golden yellow surface, uniform color, shiny, potato-specific flavor, pure fragrance, no peculiar smell, suitable crispness and shape It is relatively round, with fine and uniform pores and no large ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com