Carbon tubular oxygen reduction cathode microbial fuel cell and preparation method thereof

A technology of fuel cells and microorganisms, applied in biochemical fuel cells, battery electrodes, circuits, etc., can solve the problems of secondary pollution costs of chemical cathodes, high cost of metal cathode catalysts, unsuitable for large-scale practical application, etc., and achieve good application prospects, Low cost, the effect of reducing production and processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

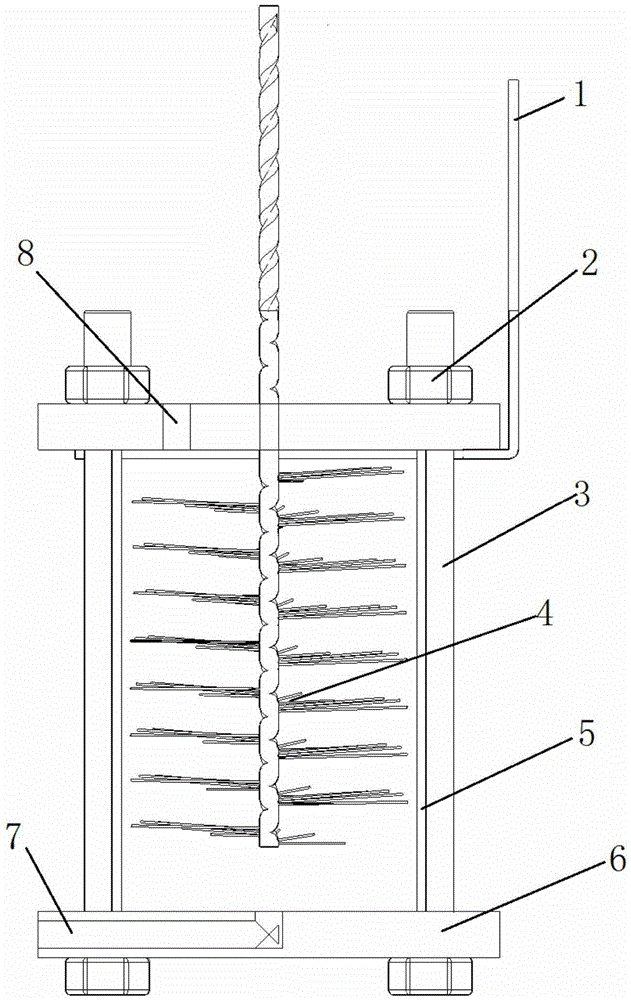

[0024] Embodiment 1: The preparation method of carbonaceous tubular oxygen reduction cathode microbial fuel cell, comprising the following steps:

[0025] A. Carbonization of cathode material: Place the prepared fresh bamboo tube in an oven and bake it at 80°C for 7 days to ensure that the bamboo tube has been completely dehydrated; then place the dried bamboo charcoal in a high-temperature atmosphere furnace and vacuumize , After filling with nitrogen, heat up to 900°C at a heating rate of 1-3°C / min. 3 / min carbonization for 2 hours, lower the furnace temperature to below 100°C and take out the bamboo tube; then place the bamboo tube in the air environment, and carry out heat treatment in a 350°C oven for 2 hours, and then heat-treated the inner surface of the bamboo tube Polish the outer surface to obtain a bamboo charcoal tube with a wall thickness of about 2 to 3 mm and a certain length.

[0026] B. Preparation of cathode: After cleaning and drying the bamboo charcoal tub...

Embodiment 2

[0029] A carbonaceous tubular oxygen reduction cathode microbial fuel cell preparation method, comprising the following steps:

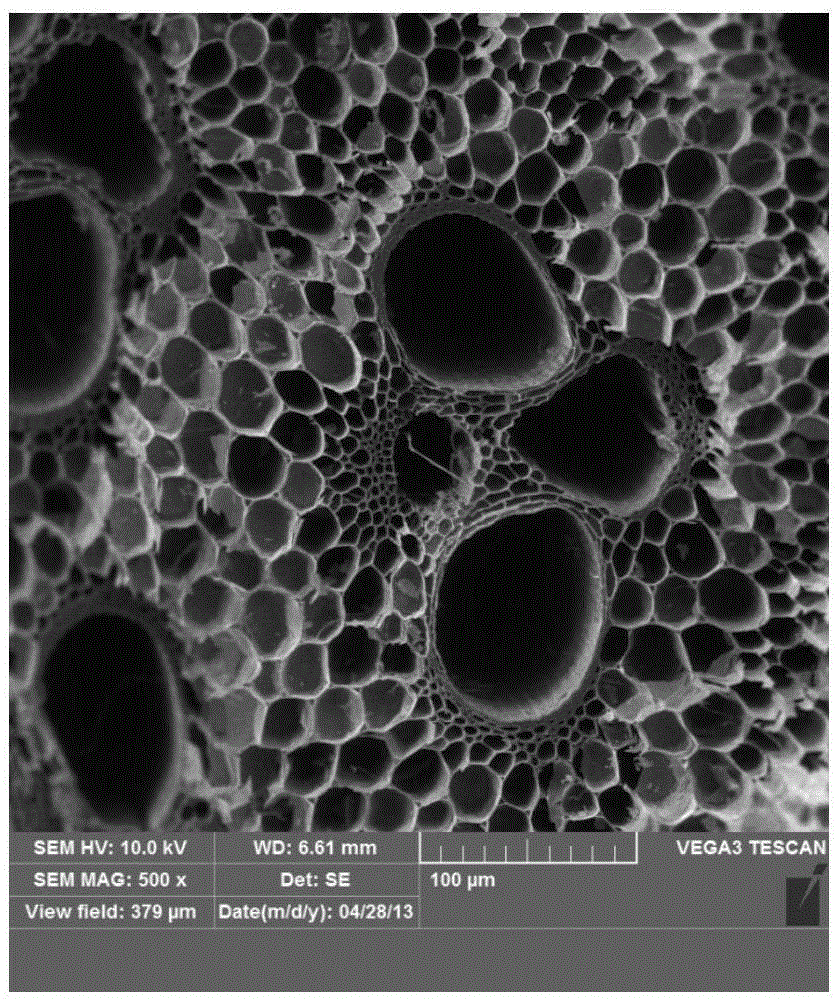

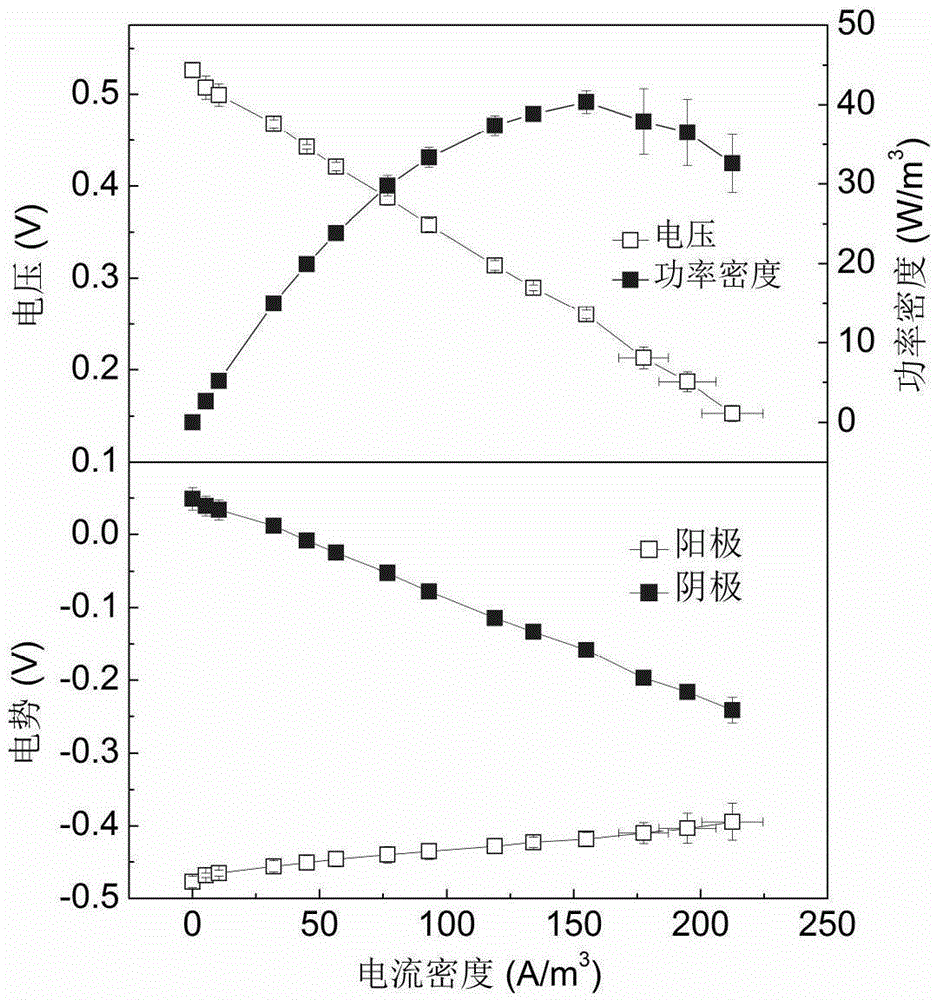

[0030] A. Carbonization of cathode materials: Fresh bamboo tubes were used as precursors. Place the prepared fresh bamboo tubes in an oven with an inner diameter of 5 cm and a length of 12 cm, and bake them at 40°C for 2 days and at 80°C for 3 days to ensure that the bamboo tubes are completely dehydrated. Place the dried bamboo charcoal in a high-temperature atmosphere furnace, vacuumize, fill with nitrogen, and then heat it to 1000°C at a rate of 1.5°C / min. Under nitrogen atmosphere, the nitrogen flow rate is 250cm 3 / min carbonization for 2.5 hours, take out the bamboo tube when the furnace temperature drops below 100°C; arrange the carbonized bamboo tube under a scanning electron microscope to observe its microscopic characteristics, and find that the carbonized bamboo charcoal can maintain rich porosity, which is a material Transmission provides...

Embodiment 3

[0034] Example 3: A method for preparing a carbonaceous tubular oxygen reduction cathode microbial fuel cell. The difference between this method and Example 2 is that the separation membrane is a polytetrafluoroethylene membrane. After the battery is prepared and assembled in this way, the waste water of 200COD, 500COD, 1000COD and 1500COD are treated respectively, and the COD removal efficiency and Coulombic efficiency are as follows: Figure 4 shown. In the case of COD, this carbon tubular oxygen reduction cathode microbial fuel cell can achieve a high COD removal rate and has a good wastewater treatment capacity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com