Preparation method and product of heteroatom-doped graphene/carbon-based material with core-shell structure

A carbon-based material, core-shell structure technology, applied in the field of materials, can solve the problems of graphene oxide structure collapse, reduce material catalytic performance, complicated steps, etc., achieve high oxygen reduction catalytic activity, improve oxygen reduction performance, and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

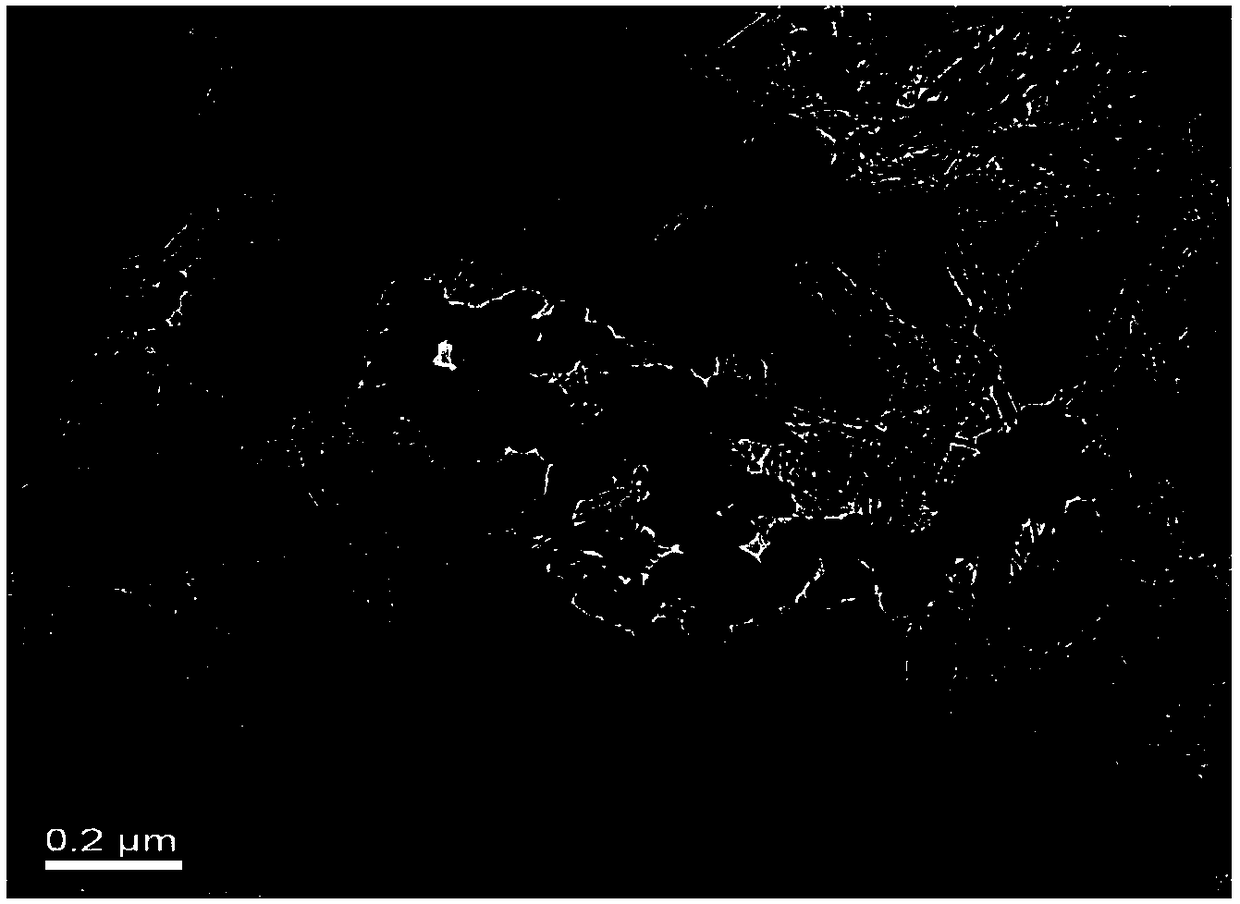

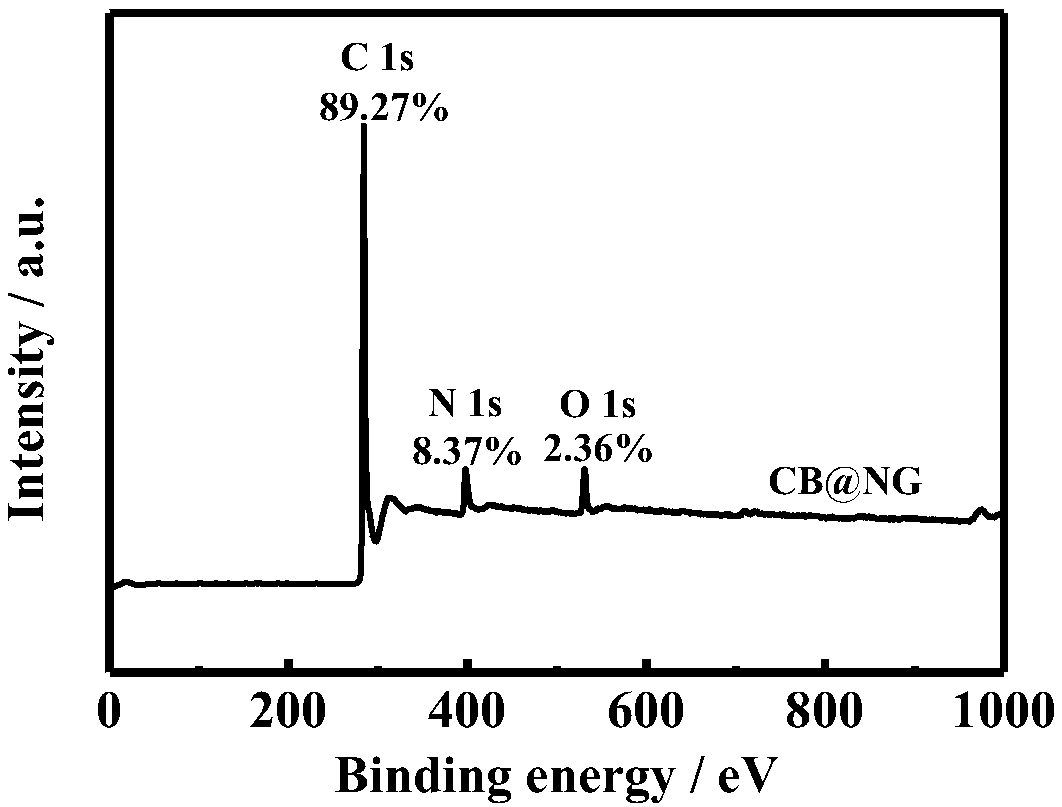

[0052] Preparation of heteroatom-doped graphene / carbon-based materials with core-shell structure

[0053] (1) Ultrasonic dispersion of conductive carbon black in cetyltrimethylammonium bromide solution to obtain conductive carbon black dispersion, wherein, cetyltrimethylammonium bromide solution The massfraction of ammonium bromide is 0.005%;

[0054] (2) graphene oxide is ultrasonically dispersed in water to obtain a graphene oxide dispersion;

[0055] (3) After the conductive carbon black dispersion obtained in step (1) is mixed with the graphene oxide dispersion obtained in step (2), a mixed solution is obtained, and the mass ratio of graphene oxide and conductive carbon black in the mixed solution 10:1;

[0056] (4) Add mass fraction to the mixed solution obtained in step (3) and be 50% cyanamide aqueous solution, after stirring evenly, be 60-110mbar in space, the temperature is rotary evaporation under the condition of 60 ℃, finally at 95 ℃ Under drying 8h, make cyanam...

Embodiment 2

[0066] Preparation of heteroatom-doped graphene / carbon-based materials with core-shell structure

[0067] (1) Ultrasonic dispersion of acetylene black in the benzalkonium bromide solution to obtain the acetylene black dispersion, wherein the mass fraction of benzalkonium bromide in the benzalkonium bromide solution is 0.002%;

[0068] (2) graphene oxide is ultrasonically dispersed in water to obtain a graphene oxide dispersion;

[0069] (3) After the acetylene black dispersion obtained in step (1) is mixed with the graphene oxide dispersion obtained in step (2), a mixed solution is obtained, and the mass ratio of graphene oxide and acetylene black in the mixed solution is 20 :1;

[0070] (4) adding mass fraction in the mixed liquor obtained in step (3) is the sodium sulfate solution of 40%, after stirring evenly, it is 60-110mbar at air space, and the temperature is rotary evaporation under the condition of 45 ℃, finally at 85 ℃ Drying at lower temperature for 10h makes sodi...

Embodiment 3

[0078] Preparation of heteroatom-doped graphene / carbon-based materials with core-shell structure

[0079] (1) Ultrasonic dispersion of activated carbon in octadecyl dimethyl benzyl quaternary ammonium chloride solution to obtain activated carbon dispersion, wherein, octadecyl dimethyl benzyl quaternary ammonium chloride solution The massfraction of dimethyl benzyl quaternary ammonium chloride is 0.01%;

[0080] (2) graphene oxide is ultrasonically dispersed in water to obtain a graphene oxide dispersion;

[0081] (3) after the activated carbon dispersion obtained in step (1) is mixed with the graphene oxide dispersion obtained in step (2), a mixed solution is obtained, and the mass ratio of graphene oxide and activated carbon in the mixed solution is 5:1 ;

[0082] (4) Adding mass fraction to the mixed solution obtained in step (3) is 30% potassium phosphate solution, after stirring evenly, the air space is 60-110mbar, and the temperature is rotary evaporation at 50°C, and fin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com