Multi-direction current collecting system applied to electric field fingerprint technique

An electric field fingerprint and collection system technology, which is applied in material analysis, measurement devices, instruments, etc. by electromagnetic means, can solve the problem of uneven distribution of electric field lines, and achieve the effect of improving safety and accurate detection results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

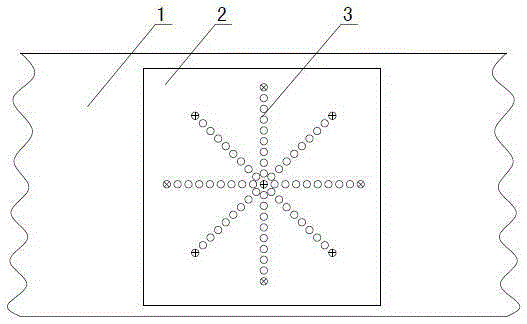

[0037] Such as figure 1 As shown, a multi-directional current collection system applied to the electric field fingerprint method includes a pipeline to be tested 1, a voltage collection area 2 is set on the outer surface of the corrosion-prone part of the pipeline to be tested 1, and a current collection area 2 is set in the current collection area 2 Acquisition array 3.

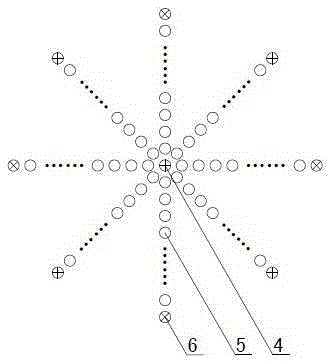

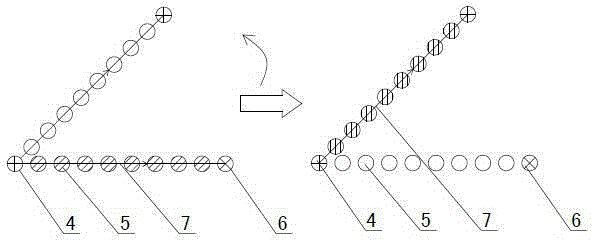

[0038] Such as figure 2 As shown, the acquisition array 3 is radial, including the current feed point 4 located at the center of the acquisition array 3, with the current feed point 4 as the center of a circle, there are multiple circles, and the radii of all the circles are from the inside to the outside with equal difference mode settings. The same number of capture electrodes 5 are evenly distributed on each circumference, and the corresponding capture electrodes 5 on each circumference are located on the same collection ray starting from the current feeding point 4, and the outer end of each collecti...

Embodiment 2

[0047] The difference between embodiment 2 and embodiment 1 is: the acquisition array 3 in embodiment 2 does not adopt the regular radial pattern in embodiment 1, but adopts an irregular radial design, such as the direction of each acquisition ray is set arbitrarily, At the same time, the number and / or spacing of the capture electrodes 5 on each collection ray can be set arbitrarily.

[0048] At the same time, since the setting direction of each collection ray and the setting number of capture electrodes 5 in it can be set arbitrarily, the tester can set some directions individually according to needs, and focus on detection, and the setting method is more flexible and reliable.

Embodiment 3

[0050] Such as Figure 4 As shown, in the multi-directional current collection system applied to the electric field fingerprint method in this embodiment, the pipeline to be tested is included 1, and a voltage collection area 2 is arranged on the outer surface of the corrosion-prone part of the pipeline to be tested 1, and in the current collection area 2 is provided with an acquisition matrix 9 .

[0051] In this field, a matrix means a rectangular array formed by several rows and columns of capturing electrodes 5 . In this embodiment, the acquisition matrix 9 adopts a composite matrix composed of two sets of matrices, and adopts a square design. The composite acquisition matrix 9 includes an m*m square matrix in the outer circle, where m is the number of first capture electrodes 501 (indicated by white circles in the figure), and m is a natural number not less than 3. In a matrix composed of m*m first capture electrodes 501, a second capture electrode 502 (represented by I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com