Eddy current heating type pipeline defect infrared imaging testing device and test method

An infrared imaging and detection device technology, which is applied in measurement devices, electrical radiation detectors, material analysis by optical means, etc., can solve problems such as pipe magnetization, and achieve the effects of short heating time, easy hand-held operation, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

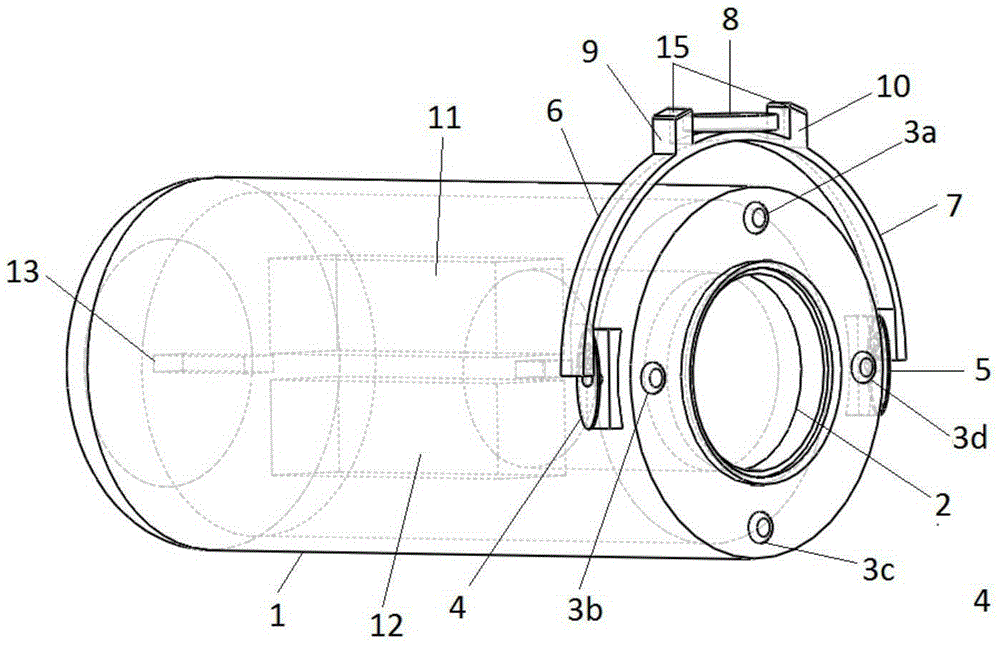

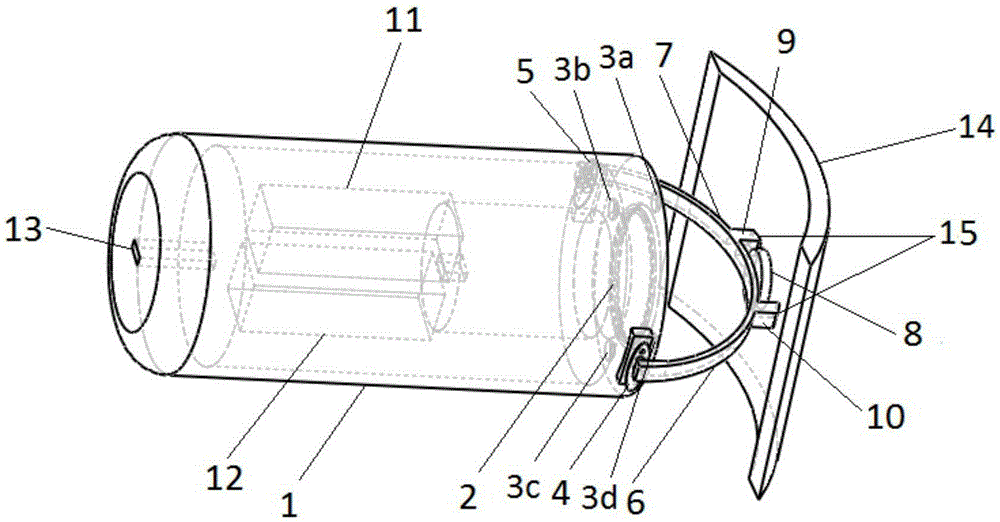

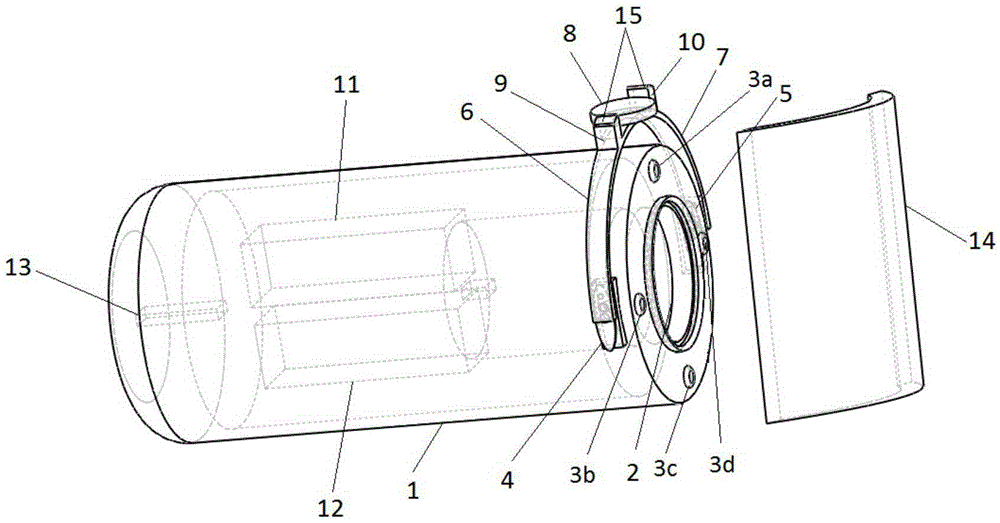

[0035] Embodiment: The present invention is funded by the National Natural Science Foundation of China (51365019), and the following eddy current heating type pipeline defect infrared imaging detection device has been designed, and the image of the buried pipeline is detected using this device and auxiliary laser point imaging technology For detection and calibration and its calibration method, the eddy current heating probe 8 is connected to the left and right steering gears 5, 4 through the left and right connecting rods 7, 6. When heating is required, the control module 12 controls the left and right steering gears 5, 4 4 drive the left and right connecting rods 7 and 6 to rotate clockwise 90 degrees, as figure 2 shown. At this time, the eddy current heating probe 8 is facing the measured object 14, and uses the principle of electromagnetic induction heating to heat the measured object 14 in a non-contact manner. When the measured object 14 is in this magnetic field, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com