Ultraviolet light-cured glass decorative sheet, and preparation method and applications thereof

A technology of ultraviolet light and decorative boards, applied in coatings, epoxy resin coatings, polyester coatings, etc., can solve the problems of low bonding strength, cumbersome grid making, and glass separation, and achieve low price and good bonding The effect of high strength and fast curing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1. Imitation wood grain glass decorative board

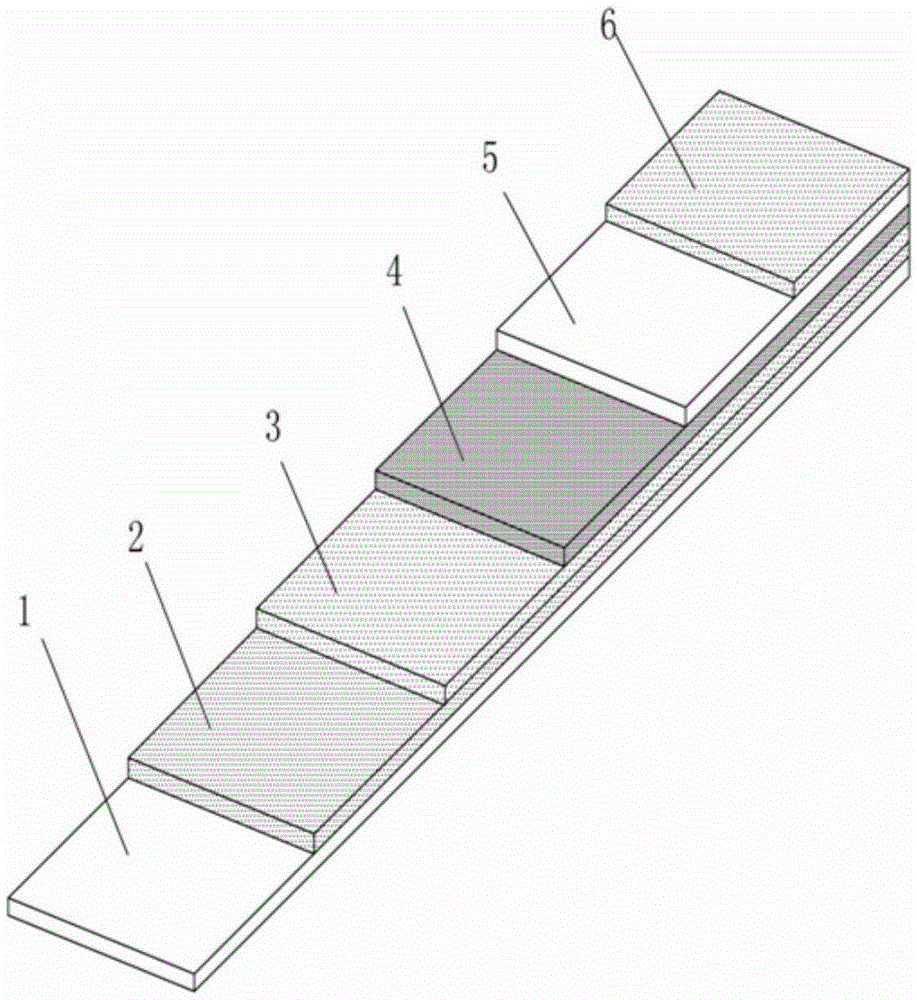

[0042] See figure 1. Choose ordinary glass with a thickness of 5mm, first remove the oil stain on the surface of the ordinary glass 1, and then roll-coat a layer of UV-curable adhesion primer 2 on the surface of the ordinary glass, with a thickness of 30um, and enter it with two 11kw ultraviolet light (high-pressure mercury lamps) , a photocuring machine with an irradiation speed of 8 m / min. After curing, a layer of UV-curable film primer 3 with a thickness of 10um is rolled on the surface of the UV-curable adhesion primer. Level off the line for 1 minute, and then transfer a layer of UV-curable transfer film 4 with wood grain on the glue under the UV-curable film. kw metal halide lamp (iodine gallium lamp), light curing machine with an irradiation speed of 8 m / min, after curing, remove the base carrier film, and then roll-coat a layer of UV curing film with a thickness of 10um on the UV curing transfer film ...

Embodiment 2

[0050] Example 2 .Imitation granite stone glass decorative panel

[0051] See figure 1 . Select toughened glass with a thickness of 5mm, first remove the oil stains on the surface of toughened glass 1, and then roll-coat a layer of UV-curable adhesion primer 2 on the surface of the toughened glass, with a thickness of 45um, and enter it with two 13kw ultraviolet light (high-pressure mercury lamps) , with a photocuring machine with an irradiation speed of 15 m / min. After curing, a layer of UV-curable film primer 3 with a thickness of 50um is rolled on the surface of the UV-curable adhesion primer, and the infrared leveling at a temperature of 80°C Level off the line for 1 minute, and then transfer a layer of UV-curable transfer film 4 printed with granite patterns on the UV-curable film under glue, and enter with two 16.8kw UV (high-pressure mercury lamps) and one 16.8 kw metal halide lamp (iron lamp), light curing machine with an irradiation speed of 15 m / min, after curing...

Embodiment 3

[0060] Example 3 .Imitation metal laser effect glass decorative panel

[0061] See figure 1 . The thickness of the plexiglass is 5mm, first remove the surface of the plexiglass 1

[0062] Oil stains, and then roll-coat a layer of UV-curable adhesion primer 2 on the surface of the plexiglass, with a thickness of 30um, and enter a light-curing machine equipped with two 9.6kw ultraviolet lights (high-pressure mercury lamps) and an irradiation speed of 20 m / min. After curing, roll-coat a layer of 15um thick UV-curable film primer 3 on the surface of the UV-curable adhesive primer, level it under the infrared leveling line at a temperature of 80°C for 1 minute, and then apply it under the UV-curable film A layer of UV-curable transfer film 4 printed with metal laser is transferred on the glue, and it is equipped with two 16.8kw ultraviolet light (high pressure mercury lamp) and one 16.8kw metal halide lamp (iron lamp), and the irradiation speed is 20 m / min light curing machine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com