Mineral sorting device, mineral processing production system and mineral sorting method

A mineral separation and mineral technology, applied in chemical instruments and methods, solid separation, separating solids from solids with airflow, etc., can solve the problem of unsatisfactory separation effect of mineral separation devices, inability to achieve effective mineral dispersion, Reduce the service life of the screening mechanism and other problems, to improve the effect of mineral separation, improve the quality of mineral separation, and ensure the effect of decentralization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

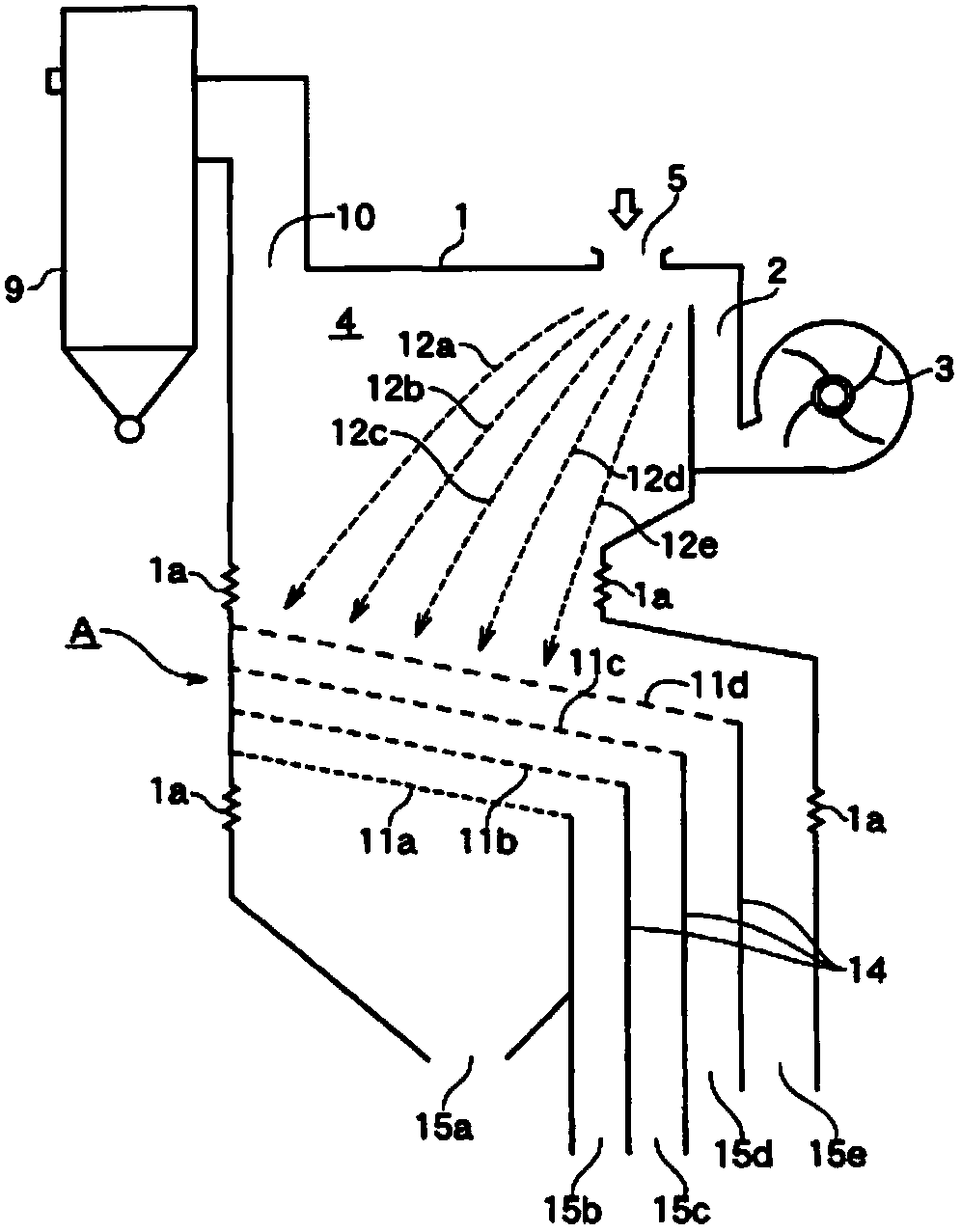

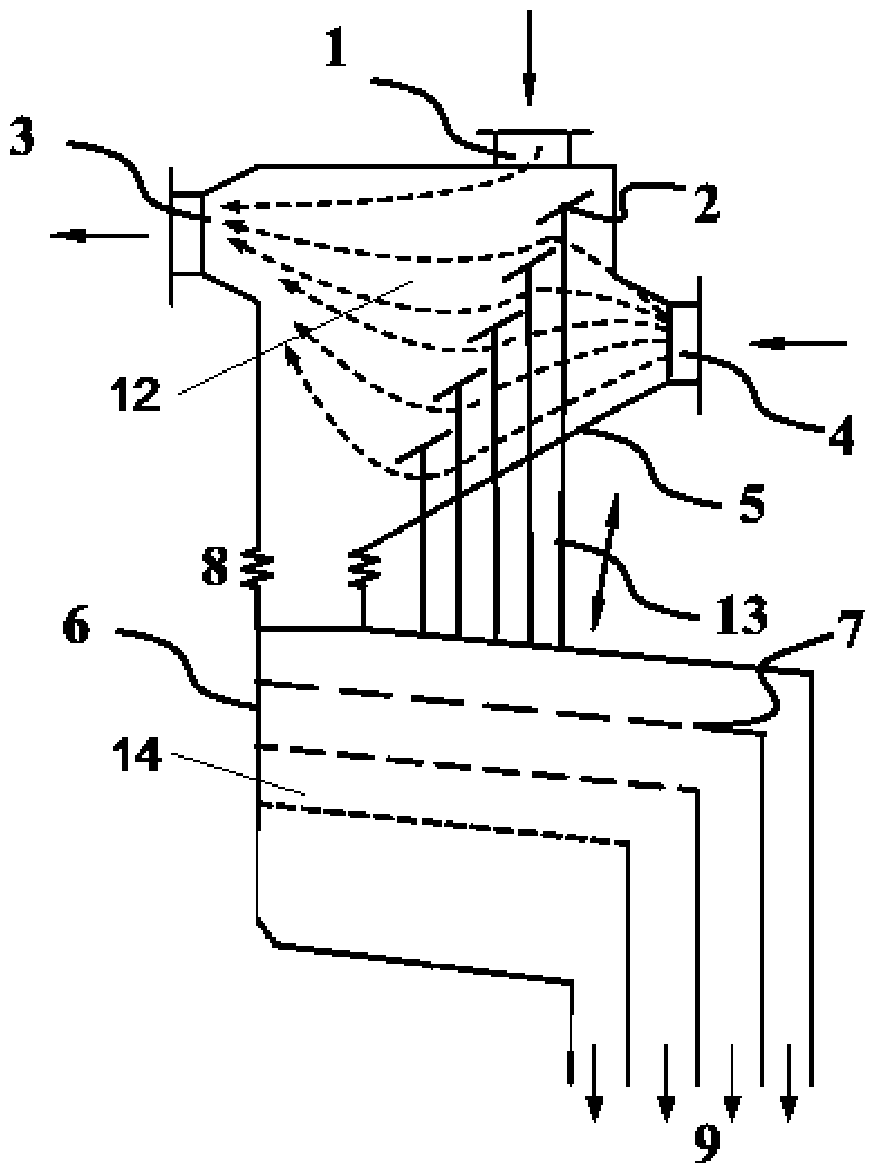

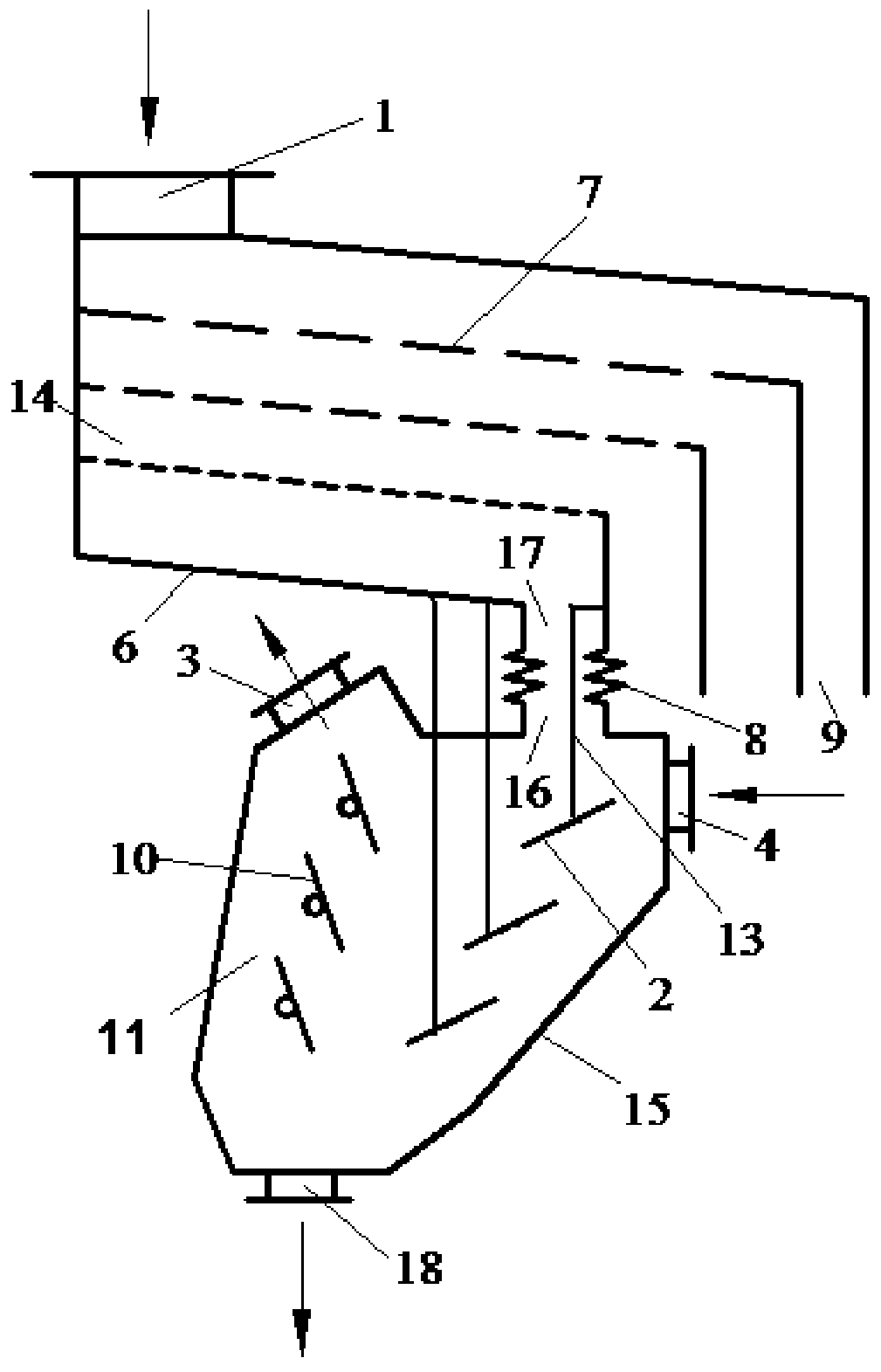

[0046] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and the protection scope of the present invention is not limited to the following specific embodiments. .

[0047] In the following description, in order to more clearly describe some orientation words involved in the technical solution of the present invention or technical features containing orientation, such as "falling", "upper", "upper", "lower", "lower", etc. , are all technical meanings according to the orientation of the mineral sorting device of the present invention during use. No matter how the orientation of the mineral sorting device is placed during production and transportation, as long as it is equivalent to the technical features of the present invention according to the installation orientation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com