A kind of stainless steel microbial electrode and its preparation method and application

A microbial electrode and stainless steel technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of poor microbial adhesion on stainless steel surfaces, reduced corrosion resistance of stainless steel substrates, and difficulty in obtaining high-performance bio-electrodes, and achieve excellent corrosion resistance. high stability and microbial adhesion, easy to scale production and application, excellent electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The stainless steel microbial electrode is prepared by the following method:

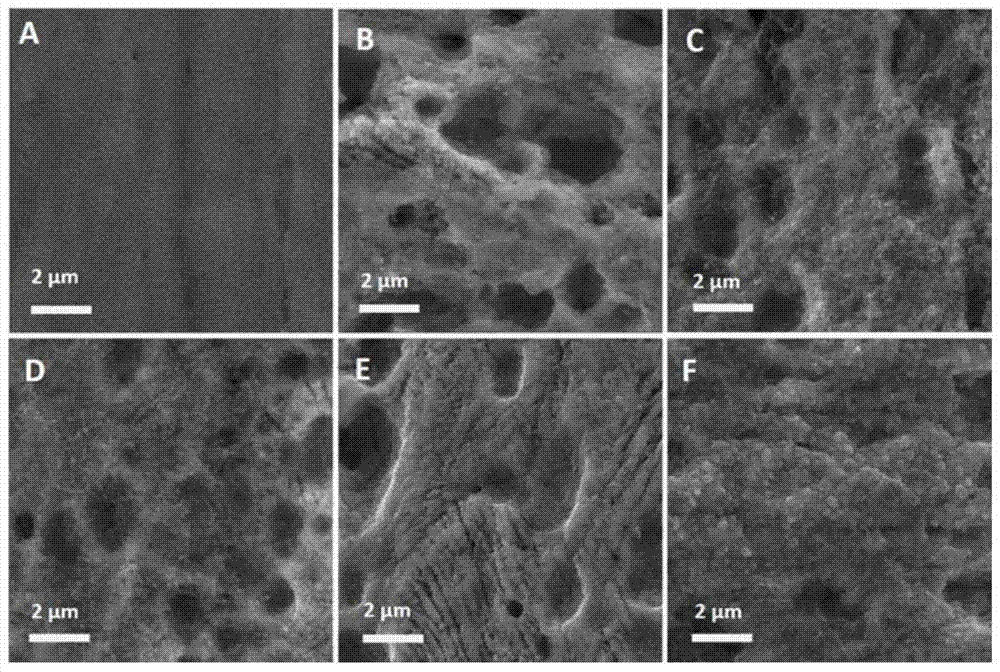

[0037] (1) Stainless steel material (scanning electron microscope picture as figure 1 -As shown in -A) surface acid treatment: put the stainless steel material into the sulfuric acid aqueous solution with a concentration of 1mol / L and soak it for 6h for surface treatment. The treated stainless steel material has a rough surface, as shown in the scanning electron microscope figure 1 -B shown;

[0038] (2) Preparation of nano-carbon material dispersion: uniformly disperse carbon black nanoparticles in ethanol to form a uniform nano-carbon material dispersion; uniformly disperse carbon black 5g in every liter of dispersion medium;

[0039] (3) Preparation of nano-carbon-stainless steel composite material: soak the stainless steel material obtained after acid treatment in step (1) in the nano-carbon material dispersion obtained in step (2), take it out after soaking for 5min, and store it under ...

Embodiment 2

[0042] The operation method of Example 2 is the same as that of Example 1, except that the heat treatment temperature in step 4 is 300° C. for 30 minutes, and the stainless steel microbial electrode is marked as electrode B.

Embodiment 3

[0044] The operation method of Example 3 is the same as that of Example 1, except that the temperature of the heat treatment in step 4 is 450° C. and the treatment time is 5 minutes. The stainless steel microbial electrode is marked as electrode C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com