Lithium battery negative electrode additive, lithium ion battery, preparation method and application

An additive, lithium battery technology, applied in battery electrodes, non-aqueous electrolyte battery electrodes, secondary batteries, etc., can solve problems such as single increase of gram capacity or first efficiency, and achieve the goal of reducing adverse effects, improving energy density, and easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

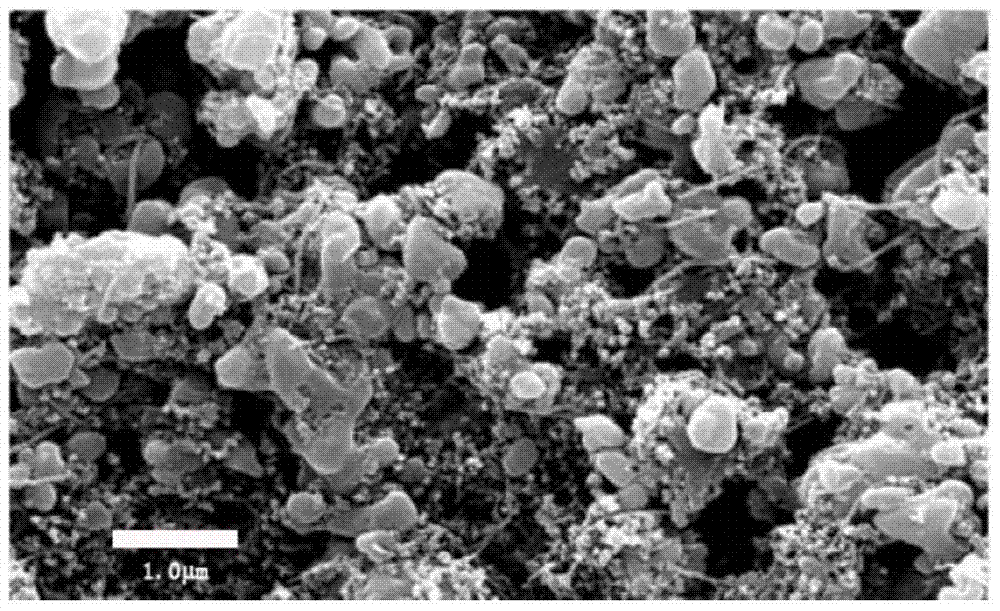

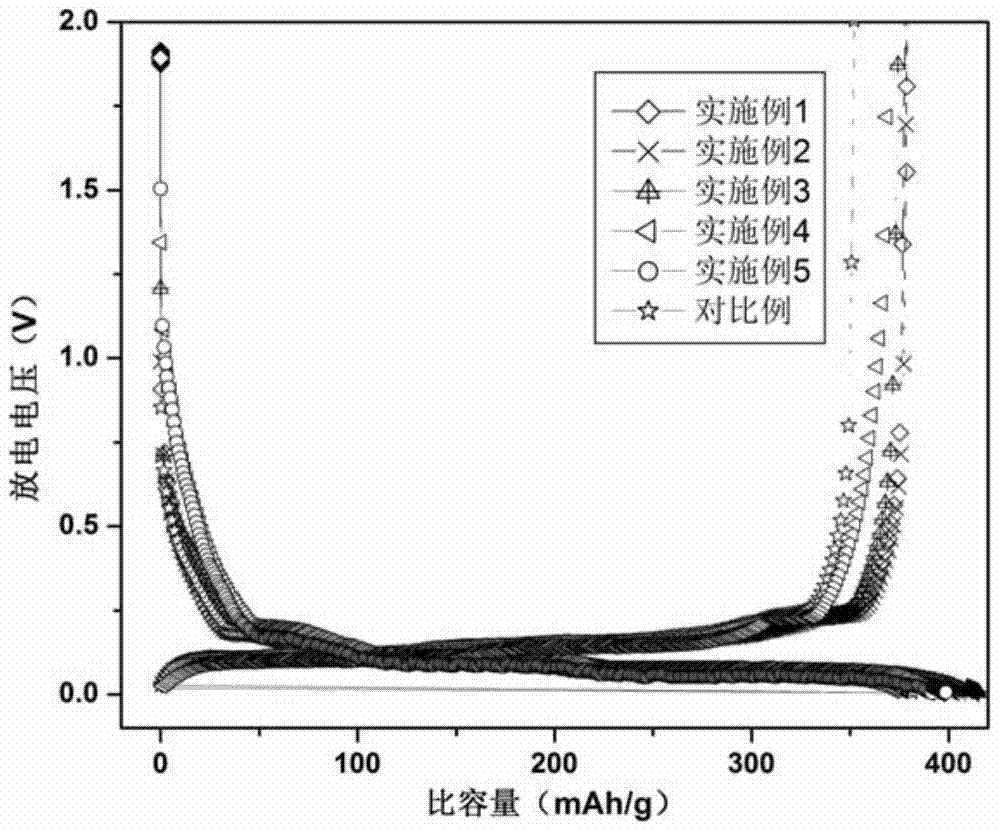

[0031] The lithium battery negative electrode additive in this embodiment has a core-shell structure, the inner core is composed of nano-silicon powder, lithium powder composite, and hollow carbon spheres, and the outer shell is mainly composed of carbon nanotubes, sodium dodecylbenzenesulfonate, and NaF; preparation Proceed as follows:

[0032] 1) First, use a three-dimensional mixer to mix 50g of nano-silicon powder, 5g of lithium powder composite (the inner core is 1g of lithium powder, and the outer core is 4g of polymethyl ethyl oxide, the preparation method is the same as that of Example 1 in patent CN103779572A), 60g of hollow carbon The balls were mixed uniformly at the dew point of -60°C to obtain mixture A for later use; at the same time, 10g of carbon nanotubes and 5g of sodium dodecylbenzenesulfonate were added to 100g of carbon tetrachloride solvent, and stirred to mix uniformly to obtain a mixture B standby;

[0033] 2) Add mixture A to mixture B at a dew point ...

Embodiment 2

[0035] The lithium battery negative electrode additive in this embodiment has a core-shell structure, the inner core is composed of nano-silicon powder, lithium powder composite, and hollow carbon spheres, and the outer shell is mainly composed of carbon nanotubes, sodium dodecylbenzenesulfonate, and NaCl; preparation Proceed as follows:

[0036] 1) First, use a three-dimensional mixer to mix 10g of nano silicon powder, 0.1g of lithium powder composite (the inner core is 0.01g of lithium powder, and the outer core is 0.09g of polymethyl methacrylate), and 20g of hollow carbon spheres at a dew point of -50°C Mix evenly under the conditions to obtain mixture A for later use; at the same time, add 20 g of carbon nanotubes and 10 g of sodium dodecylbenzenesulfonate to 100 g of toluene solvent, stir to make it evenly mixed, and obtain mixture B for later use;

[0037] 2) Add mixture A to mixture B at the dew point of -60°C, stir and mix for 3 hours, then heat-treat at 400°C for 1 h...

Embodiment 3

[0039] The lithium battery negative electrode additive in this embodiment has a core-shell structure, the inner core is composed of nano-silicon powder, lithium powder composite, and hollow carbon spheres, and the outer shell is mainly composed of carbon nanotubes, sodium dodecylbenzenesulfonate, and NaCl; preparation Proceed as follows:

[0040] 1) First, use a three-dimensional mixer to mix 70g of nano-silica powder, 10g of lithium powder composite (the inner core is 2g of lithium powder, and the outer core is 8g of polymethyl acrylate), and 80g of hollow carbon spheres at a dew point of -50°C. Obtain mixture A for later use; at the same time, add 5 g of carbon nanotubes and 2.5 g of sodium dodecylbenzenesulfonate to 100 g of tetrahydrofuran solvent, stir to make it evenly mixed, and obtain mixture B for later use;

[0041] 2) Add mixture A to mixture B at a dew point of -60°C, stir and mix for 5 hours, then heat-treat at a temperature of 500°C for 2 hours to evaporate the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com